Sponge mattress winding type packaging system

A packaging system and mattress technology, applied in the field of sponge mattress roll-type packaging systems, can solve the problems of high labor intensity, low work efficiency, and difficulty in scaling up, so as to improve work efficiency, facilitate scale expansion, The effect of reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The following examples can enable those skilled in the art to understand the present invention more comprehensively, but the present invention is not limited to the scope of the described examples.

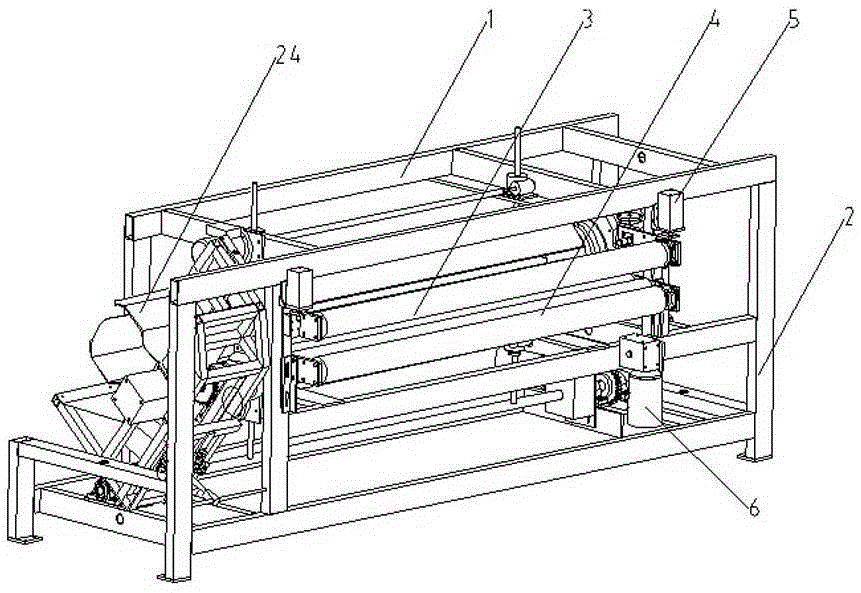

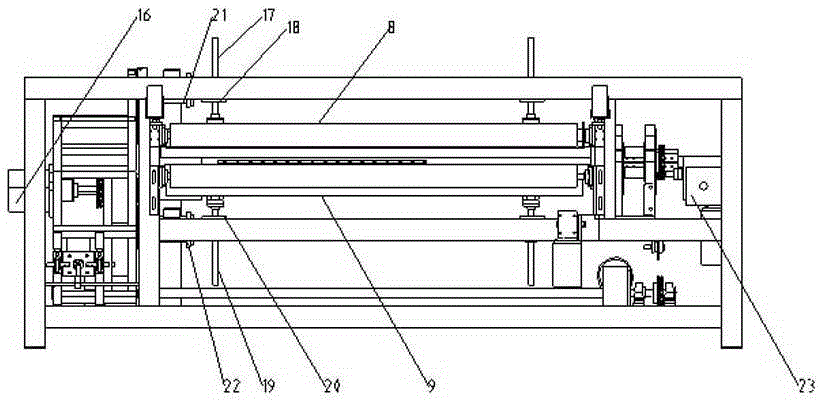

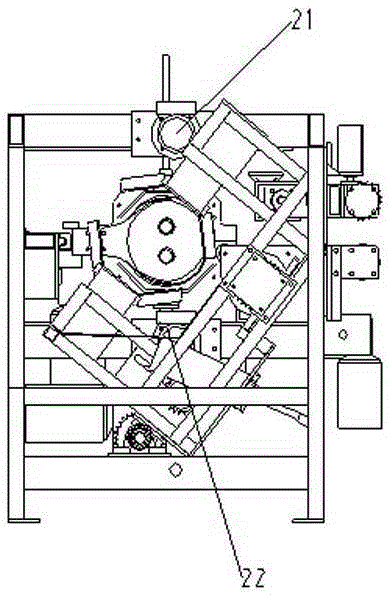

[0026] Such as figure 1 A roll-type packaging system for a sponge mattress is shown, including a winding support, a feeding mechanism, a winding mechanism and a discharging mechanism.

[0027] The winding support is a cuboid frame structure formed by several horizontal supports 1 and vertical supports 2 .

[0028] The feeding mechanism is installed on one side of the long axis direction of the winding support, including a pair of movable conveying rollers 3 and fixed conveying rollers 4 installed up and down on the side ends of the winding support. The movable conveying rollers 4 can be driven by the driving mechanism to move away from or close to the fixed conveying Roller 3, the driving mechanism includes a pair of driving cylinders A5 symmetrically arranged at both ends...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com