Improved plastic film flattening device

A technology of plastic film and flattening device, which is applied in the direction of thin material processing, transportation and packaging, winding strips, etc., can solve the problems of waste of resources, increase of waste rate, becoming waste products, etc., to prevent static electricity from hurting hands and stop The effect of static electricity hurting hands and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

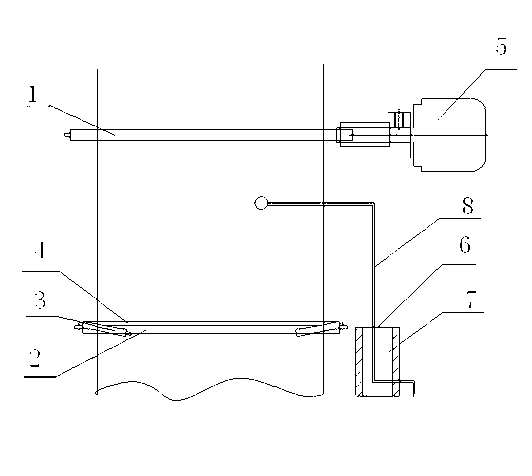

[0011] Such as figure 1 As shown, an improved plastic film flattening device of the present invention includes an upper film guide roller 1, a lower film guide roller 2, a flattening guide roller 3 and a flattening guide roller bracket 4, an upper film guide roller 1 and a stepping motor 5 connection, the flattening guide roller support 4 is installed in parallel on one side of the lower film guide roller 2, and the two ends of the flattening guide roller support 4 are respectively installed with a flattening guide roller 3, and the improved plastic film flattening device is also provided with Static eliminator 6, static eliminator 6 comprises base 7, is provided with static transmission bar 8 on base 7, and the lower end of static transmission bar 8 passes base 7 grounding, and the upper end of static transmission bar 8 extends to the surface of plastic film, and static transmission bar The upper end of 8 is spherical, and the flattening guide roller 3 is flexibly connected ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com