Anti-looseness metal hose winding method

A metal hose and anti-loosening technology, which is applied in the field of metal hose coiling of anti-loosening, can solve the problems of difficult contact and loosening of metal hoses, troublesome operation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further explained below in conjunction with the accompanying drawings and specific embodiments. It should be understood that the following specific embodiments are only used to illustrate the present invention but not to limit the scope of the present invention.

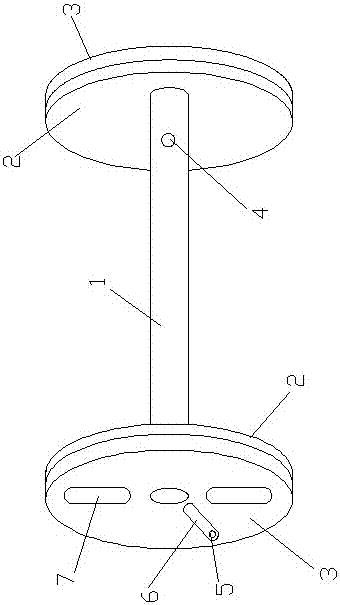

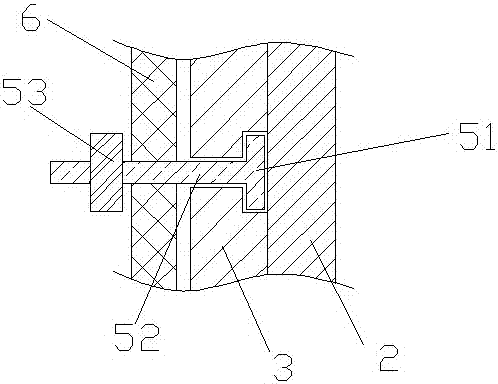

[0023] figure 1 It is a structural schematic diagram of the present invention, figure 2 It is a cross-sectional view of the connection between the positioning plate and the screw of the present invention. The label names in the accompanying drawings are: reel body 1, buffer gasket 2, end cap 3, round hole 4, screw 5, screw head 51, screw rod 52, Nut 53, positioning plate 6, strip hole 7.

[0024] The anti-loosening metal hose coiling method includes the following steps:

[0025] Step 1: Make the reel: select the hollow circular tube as the reel body, select two circular plates as the end caps, fix the two end caps on the two ends of the reel body respectively, the end caps are...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com