Full-computerized double-side seamless casting-on circular weft knitting machine

A fully computerized and circular knitting machine technology, applied in the field of knitting machinery, can solve the problems of low weaving efficiency, high manufacturing cost, and fewer yarn feeding paths, and achieve the effects of saving processing costs, improving efficiency, and increasing varieties of designs and colors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Embodiments of the present invention will be further described in detail below in conjunction with the accompanying drawings.

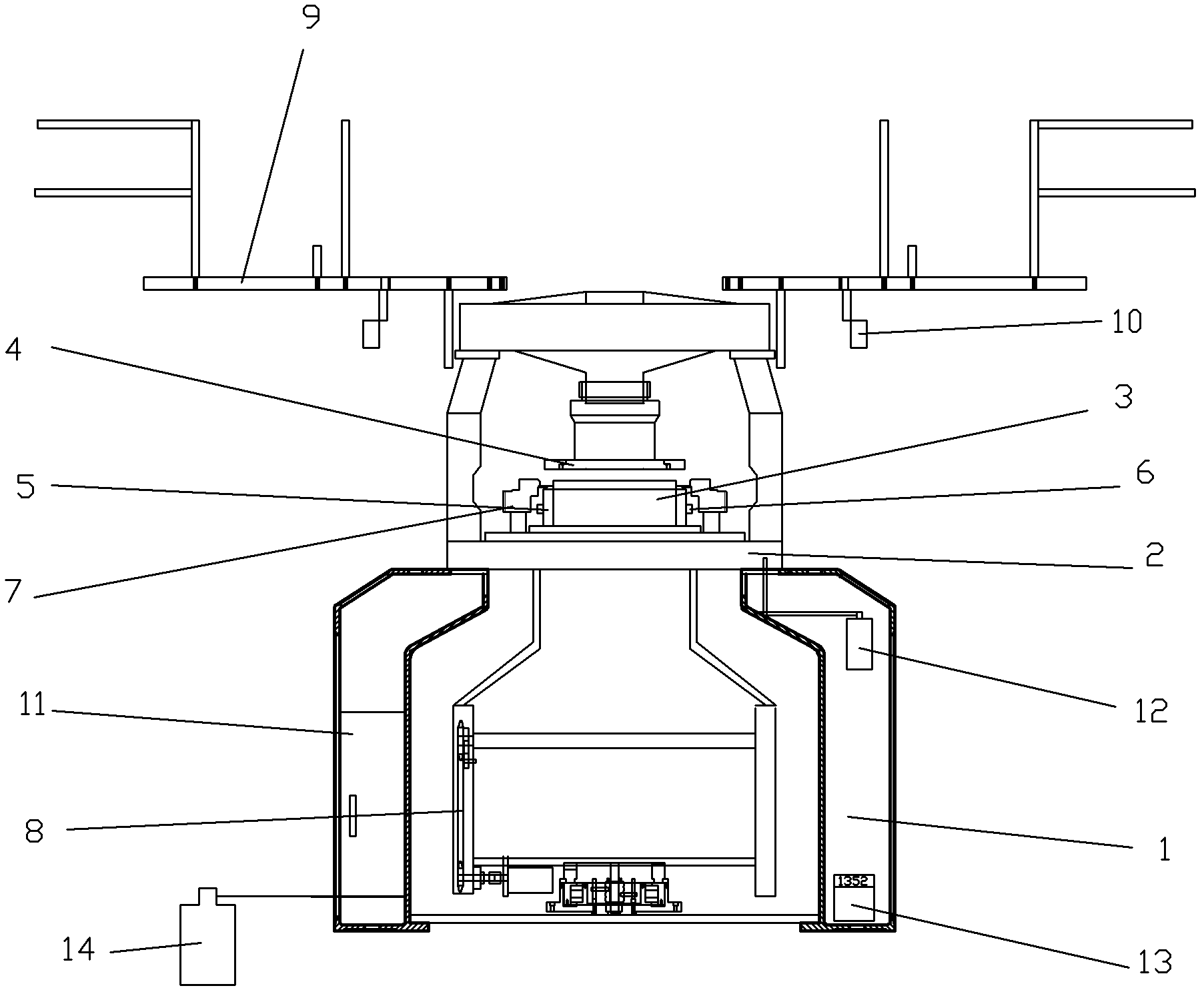

[0023] Such as figure 1 As shown, the fully computerized double-sided seamless starting circular weft machine includes a frame (1), a transmission mechanism (2), a weaving mechanism (5), an automatic density adjustment device (6), an automatic thread adjustment device (7), The motor controls the cloth rolling device (8), the creel (9), the fault alarm self-stop device (10), the computer control system (11), the main power motor (12), the frequency converter (13), and the air pump (14).

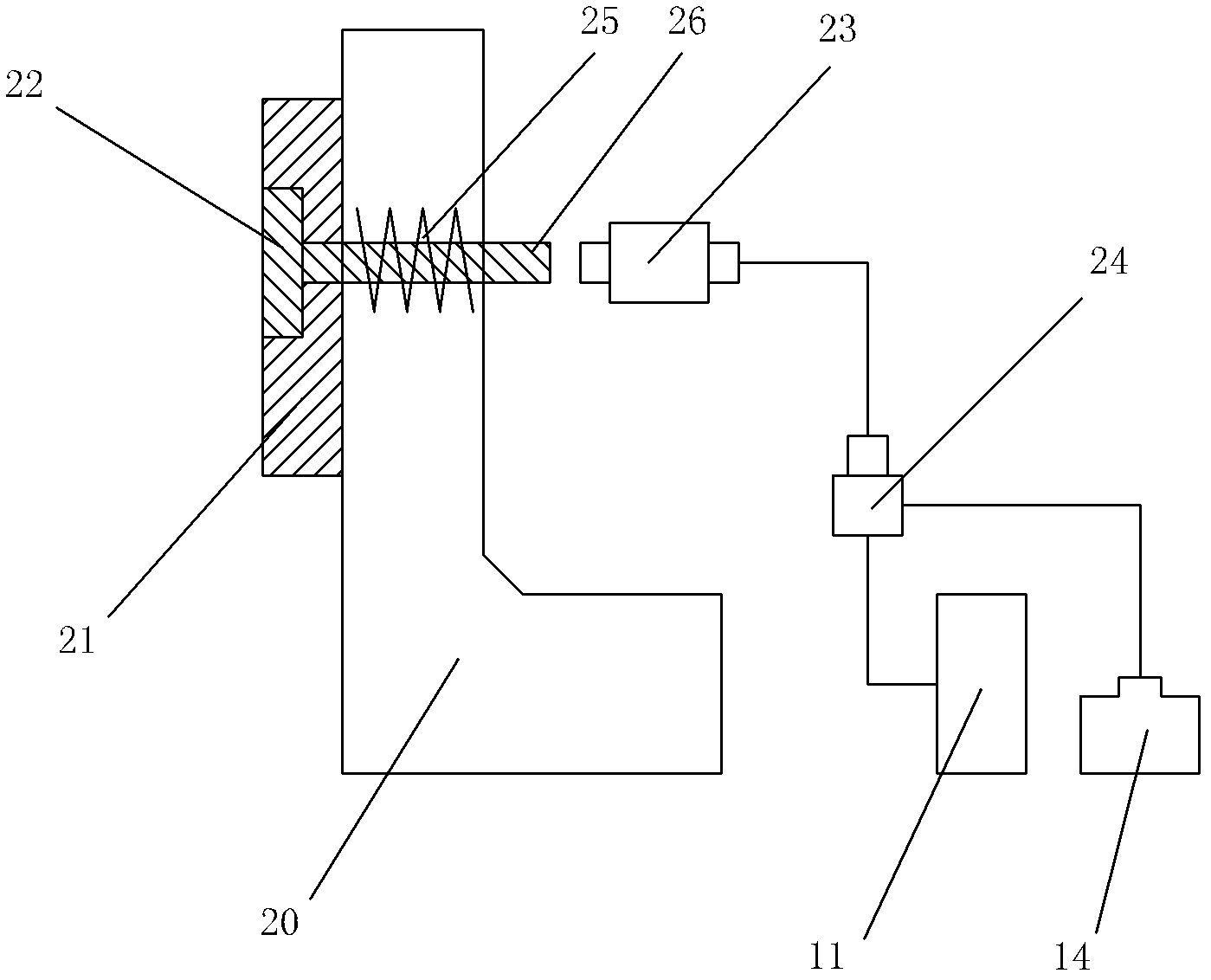

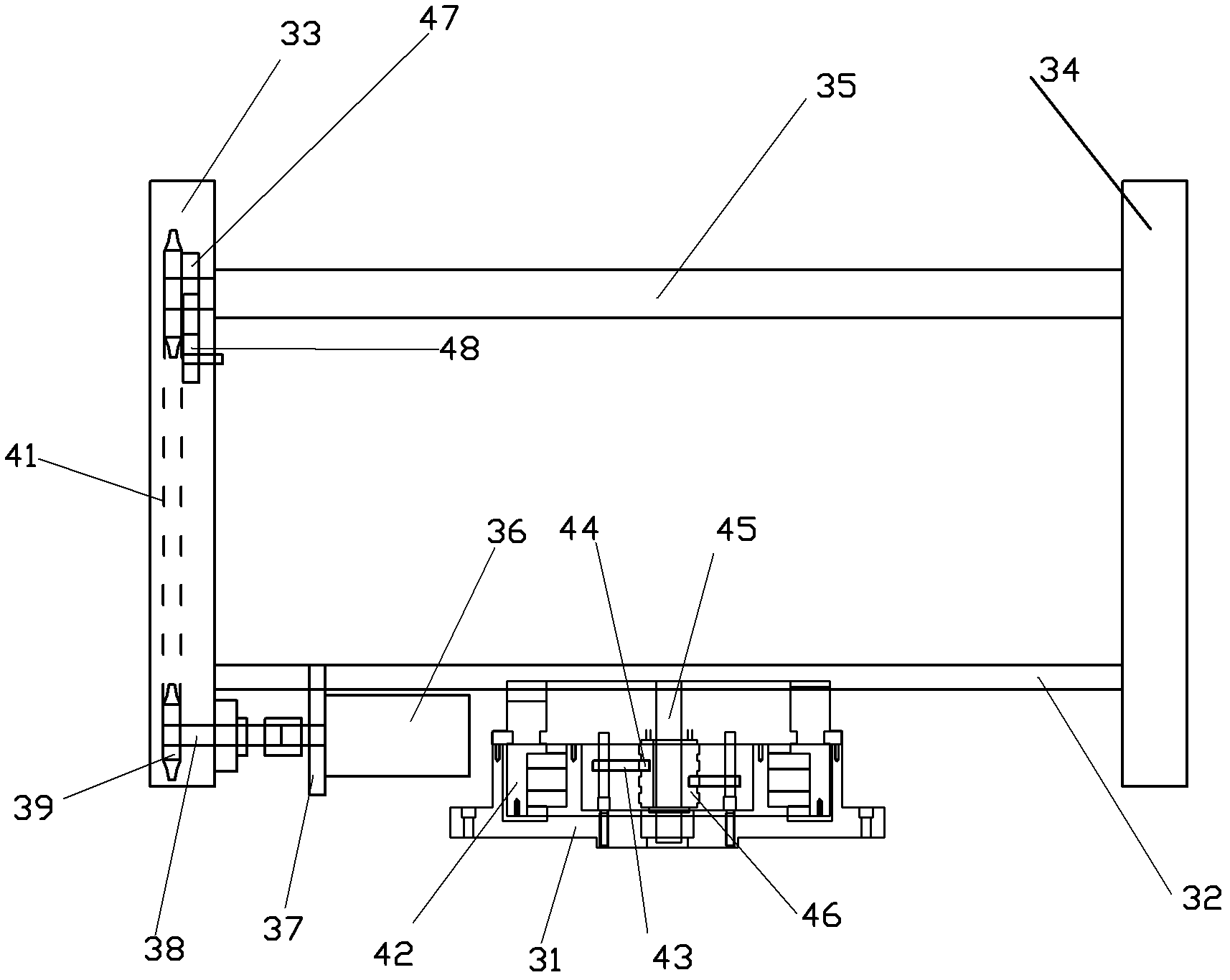

[0024] The knitting mechanism (5) comprises a needle cylinder (3), a needle cover (4), a cam assembly, and a yarn feeder, and the needle cylinder (3) and the needle cover (4) are fixed on the central part of the frame (1), The automatic density adjustment device (6) is connected in the knitting mechanism (5), and the automatic thread adjustment device (7) is i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com