Process optimization method improving rolling and threading of ultrathin strip steel

A process optimization, strip steel technology, applied in the direction of manufacturing tools, metal processing equipment, metal rolling, etc., can solve the difficulty of high-speed production in the acid rolling process of ultra-thin strip steel, affect the output, quality and efficiency of the unit, and stop the stacking of steel in the production line To improve the stability of coiling and threading, optimize the air purge pressure, and ensure the effect of coiling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

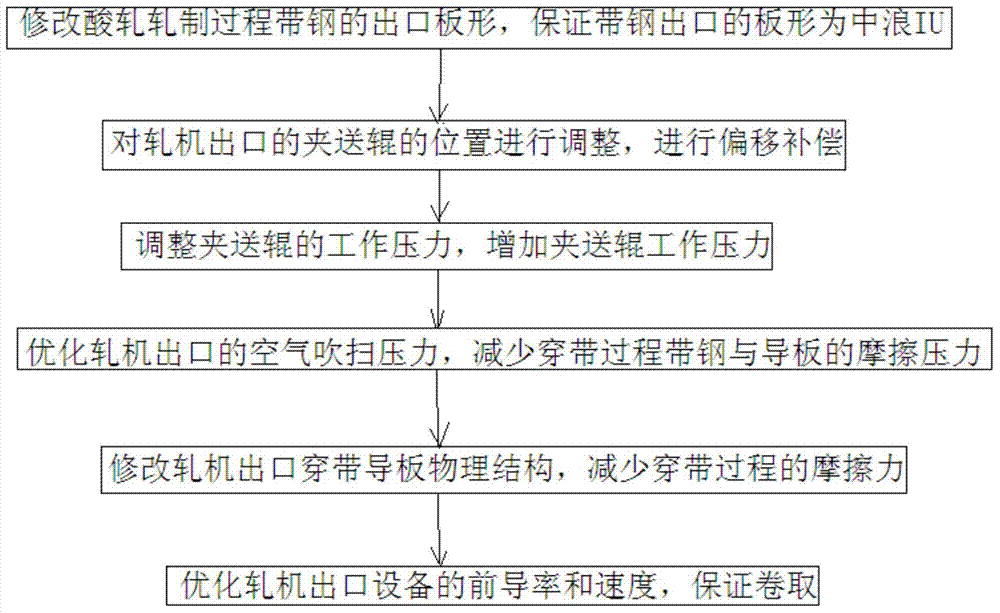

[0015] see figure 1 , an embodiment of the present invention provides a method for improving the process optimization of ultra-thin steel strip taking and threading, including

[0016] A process optimization method for improving the taking and threading of ultra-thin strip steel, characterized in that it includes:

[0017] Step 110: Modify the strip shape at the exit of the strip during the pickling rolling process to ensure that the strip exits at the strip exit as Zhonglang IU;

[0018] Step 120: Adjust the position of the pinch roll at the exit of the rolling mill, and perform offset compensation;

[0019] Step 130: Adjust the working pressure of the pinch roller, and increase the working pressure of the pinch roller;

[0020] Step 140: optimizing the air purge pressure at the exit of the rolling mill to reduce the frictional pressure between the strip steel and the guide plate during the strip threading process;

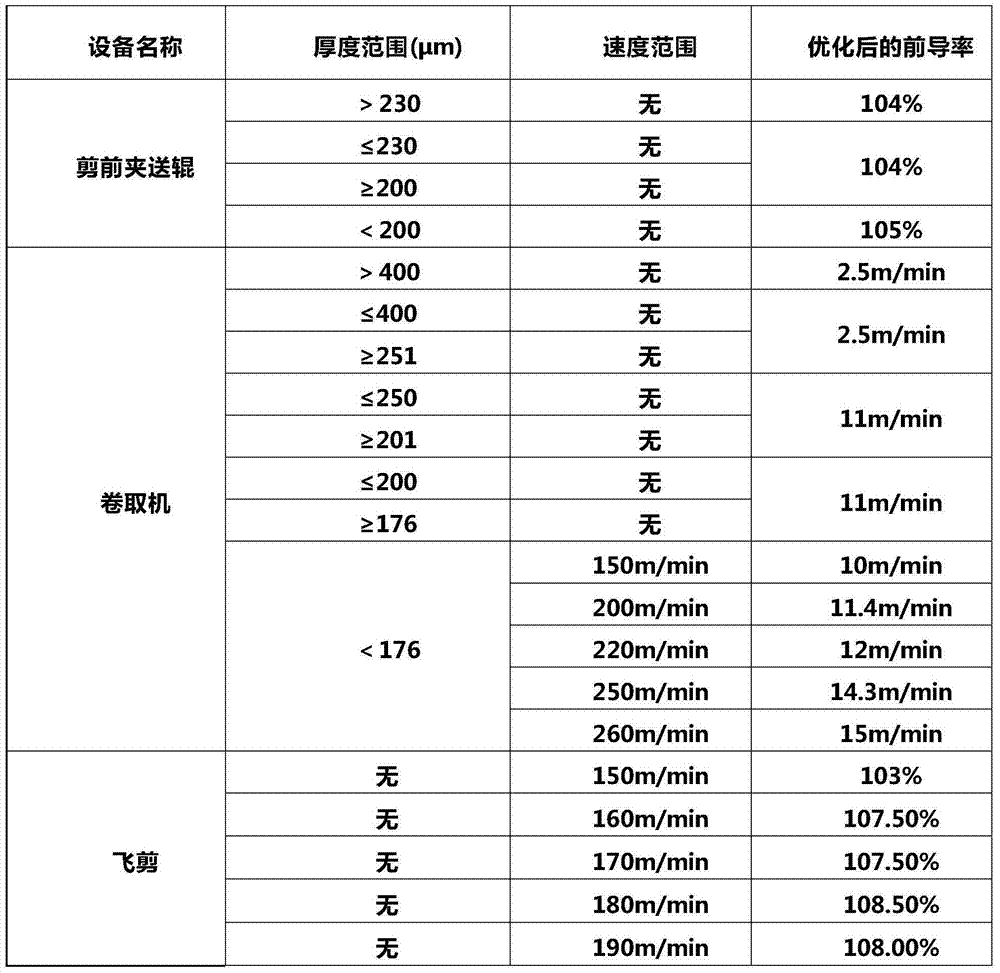

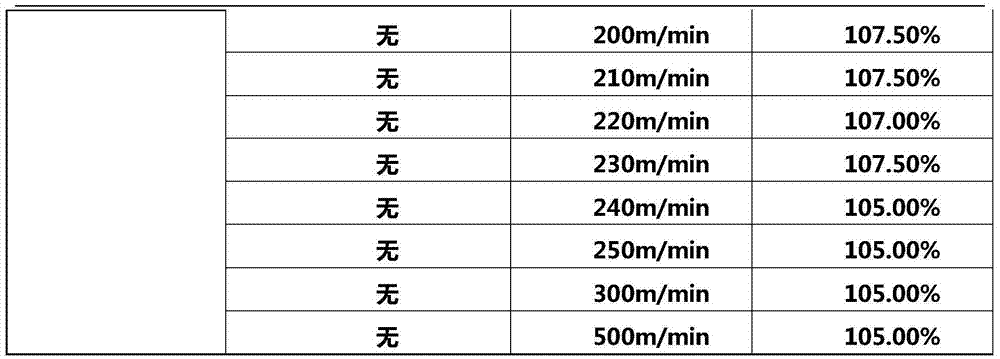

[0021] Step 150: Modify the physical structure of the st...

Embodiment 2

[0036] In order to introduce the embodiment of the present invention more clearly, the following will introduce it from the specific examples of the embodiment of the present invention.

[0037] When using the present invention to improve the process optimization method of ultra-thin strip steel taking and threading, when rolling ultra-thin strip steel, the plate shape during shearing is adjusted to 15IU of medium wave: the bending force of the work roll of the last stand is 18KN / chock, the bending force of the middle roll of the last stand is 20KN / chock, the shape of the strip is manually adjusted when the weld seam enters the rolling mill, the shape of the strip is detected by the shape detector, and the signal is fed back to the last stand, and the steel force of the last stand is Adjust and increase the bending force until the IU value of the middle wave is 15IU.

[0038] Move the upper roller of the pinch roller 2mm toward the entrance to ensure that the head of the stri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com