Fast quantitative loading station and method with super loading capacity

A loading station and capacity technology, applied in the directions of loading/unloading, transportation and packaging, conveyors, etc., can solve the problems that the volume cannot be increased without limit, cannot be increased at will, and cannot improve the loading capacity, etc., so as to improve the loading capacity. Efficiency, increased loading capacity, faster unloading effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

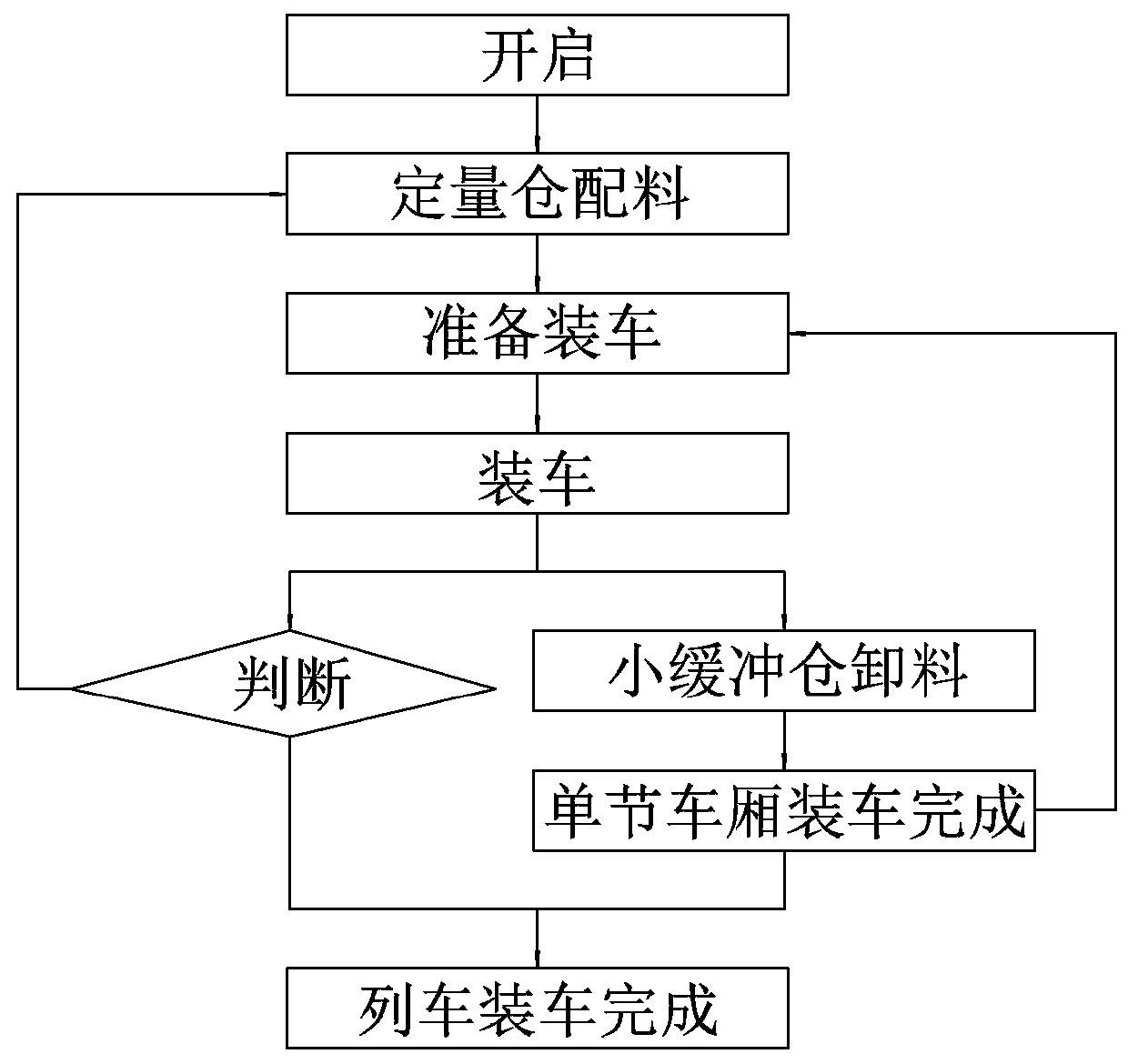

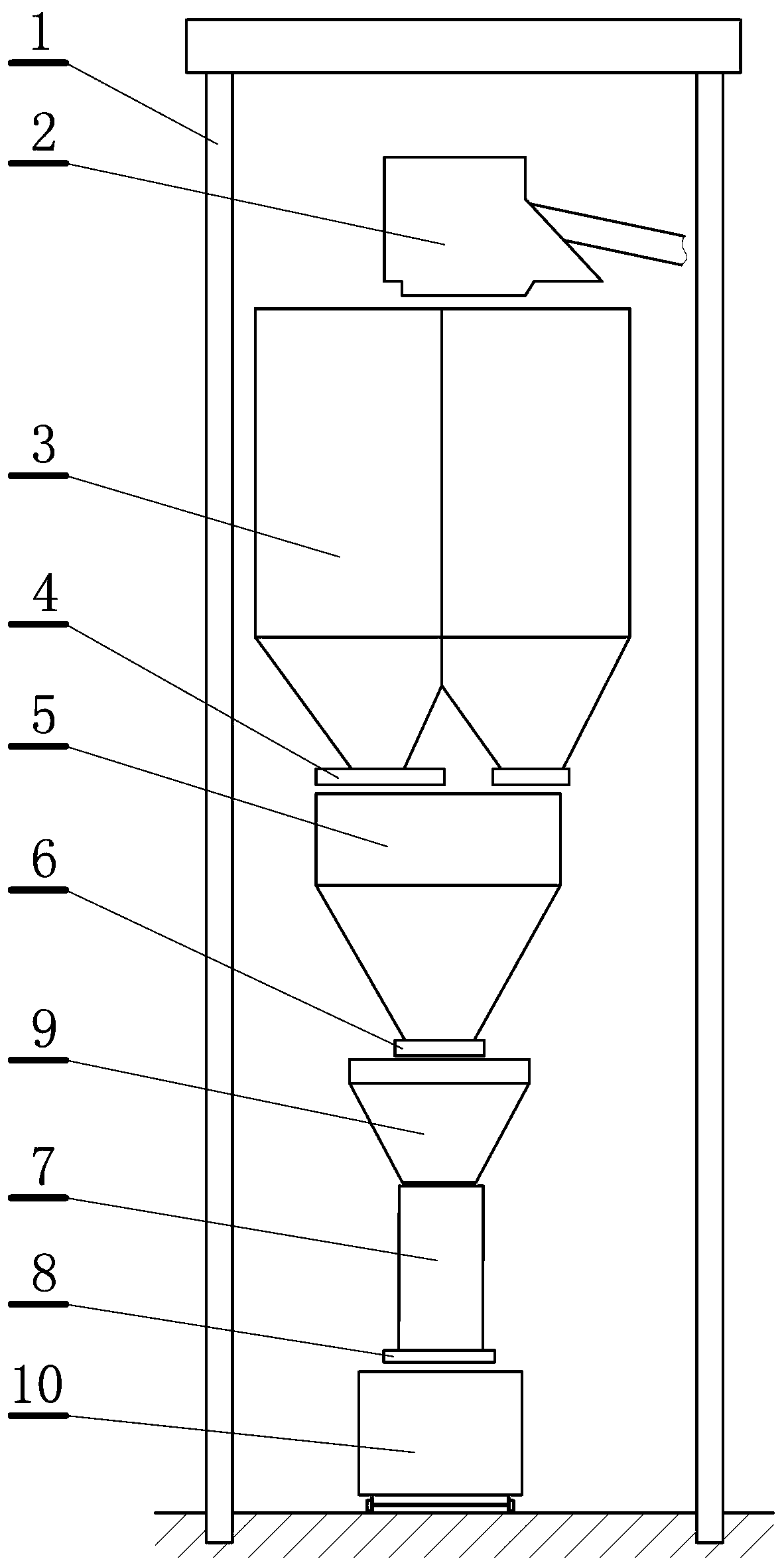

[0019] This embodiment is a fast and quantitative loading method with super large loading capacity. The loading station used in the method includes: a steel structure tower 1, and the steel structure tower is arranged sequentially from top to bottom: a belt conveyor Head 2, buffer bin 3, buffer bin batching gate 4, quantitative bin 5, quantitative bin unloading gate 6, loading chute 7, chute gate 8, a small buffer is set between the quantitative bin unloading gate and loading chute bin 9, such as figure 1 shown.

[0020] figure 1 Only a simple schematic diagram of the loading station is drawn in the paper. The actual situation is much more complicated, including hydraulic and electric control systems.

[0021] The steel structure tower is the main body of the loading station, straddles the rails, and the carriage 10 of the train passes through the bottom of the steel structure tower. The steel structure tower is fixedly installed on the ground with multiple vertical support...

Embodiment 2

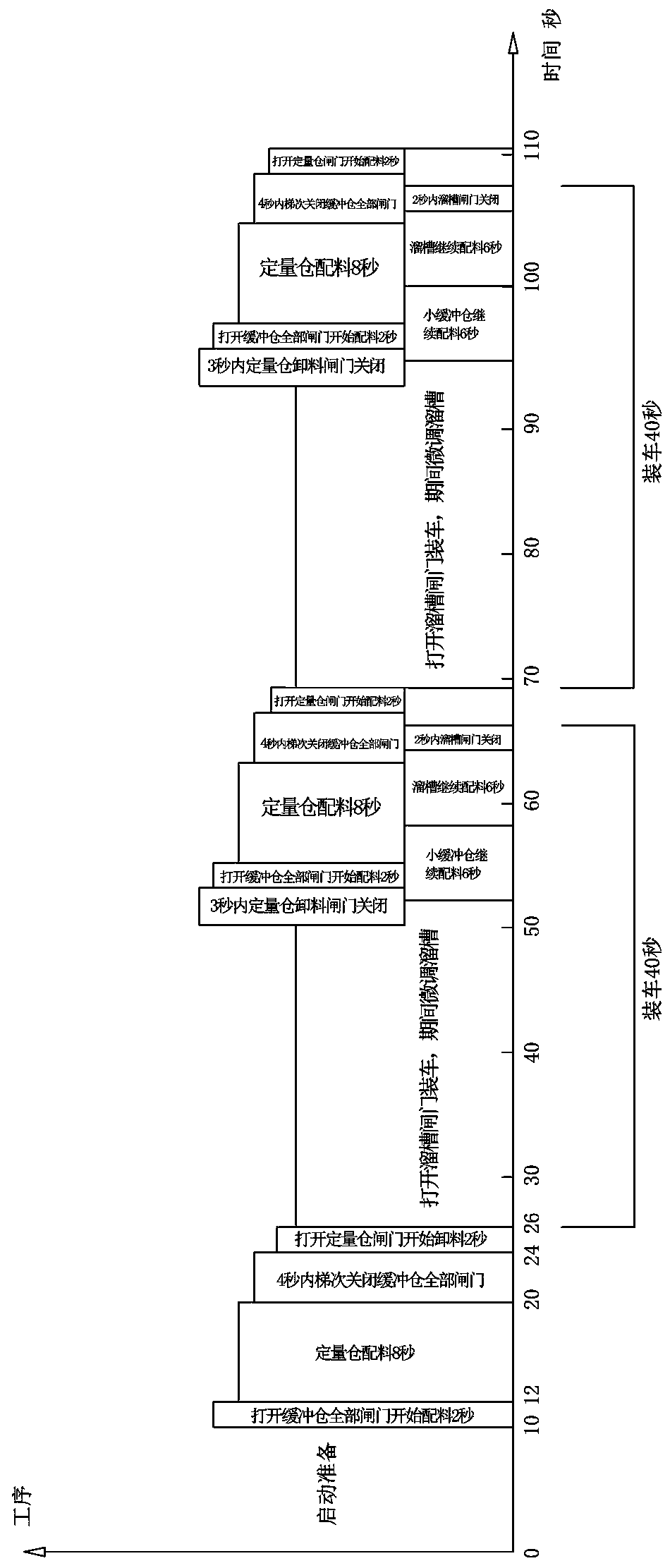

[0025] This embodiment is a loading method using the loading station. The concrete steps of described method are as follows, flow chart sees figure 2 :

[0026] Step 1: In the opening step, open the belt conveyor to continuously input bulk materials into the buffer bin, and accumulate materials in the buffer bin that exceed at least half of the volume of the quantitative bin.

[0027] This step is to batch ingredients into the buffer bin. When the belt conveyor is turned on, the batching gate of the buffer bin, the discharge gate of the quantitative bin, and the gate of the chute are all closed, which is self-evident. The capacity of the buffer bin is usually larger, generally about twice that of the quantitative bin, to ensure that sufficient materials are added to the quantitative bin without cutting off the flow.

[0028] Step 2: In the batching step of the quantitative warehouse, the batching gate of the buffer warehouse is opened to batch the ingredients in the quanti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com