Process for unloading of silver catalyst reactor and its apparatus

A silver catalyst and unloading device technology, applied in chemical instruments and methods, chemical/physical processes, etc., can solve problems such as low efficiency and poor effect, and achieve the effect of reducing unloading time, reducing losses, and facilitating recycling and reuse.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

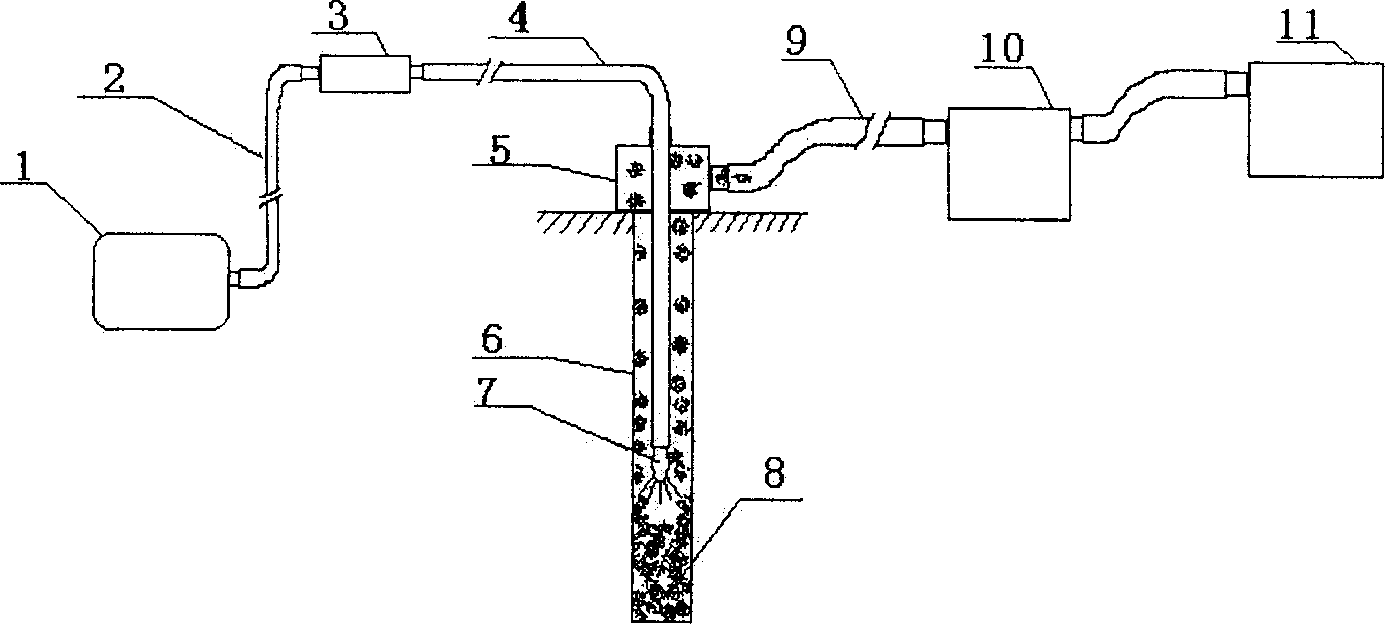

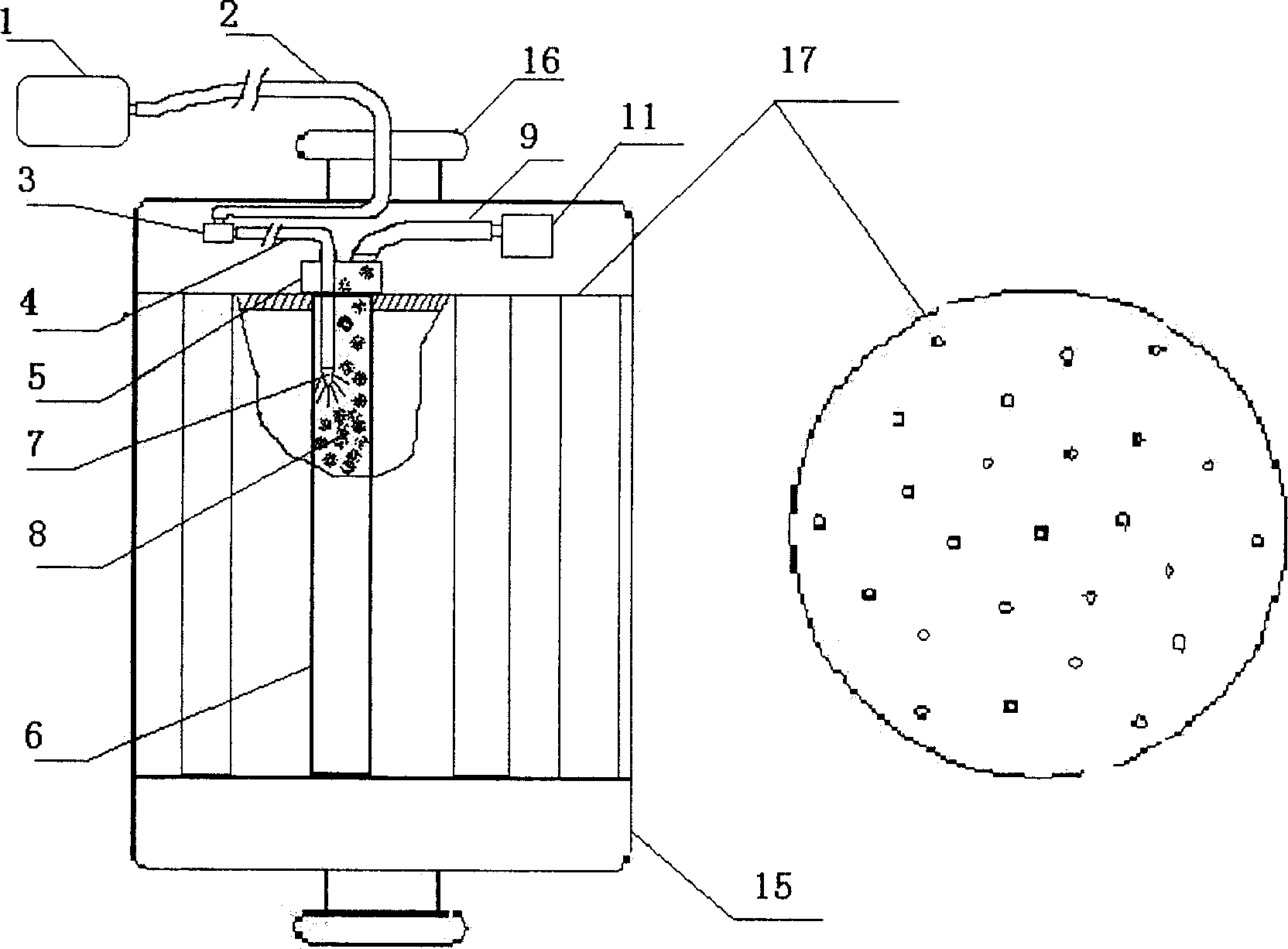

[0023] Below in conjunction with accompanying drawing, describe in detail an embodiment belonging to the present invention:

[0024] For the specific structure of this embodiment, see figure 2 , the device used is as follows:

[0025] 1. One high-pressure air pump, the maximum theoretical air flow is 0.25m 3 / min, the maximum outlet pressure is 8MPa, which provides continuous high-pressure gas;

[0026] 2. High-pressure gas delivery pipe 2 adopts Φ8×12mm polyethylene pipe, 20m long;

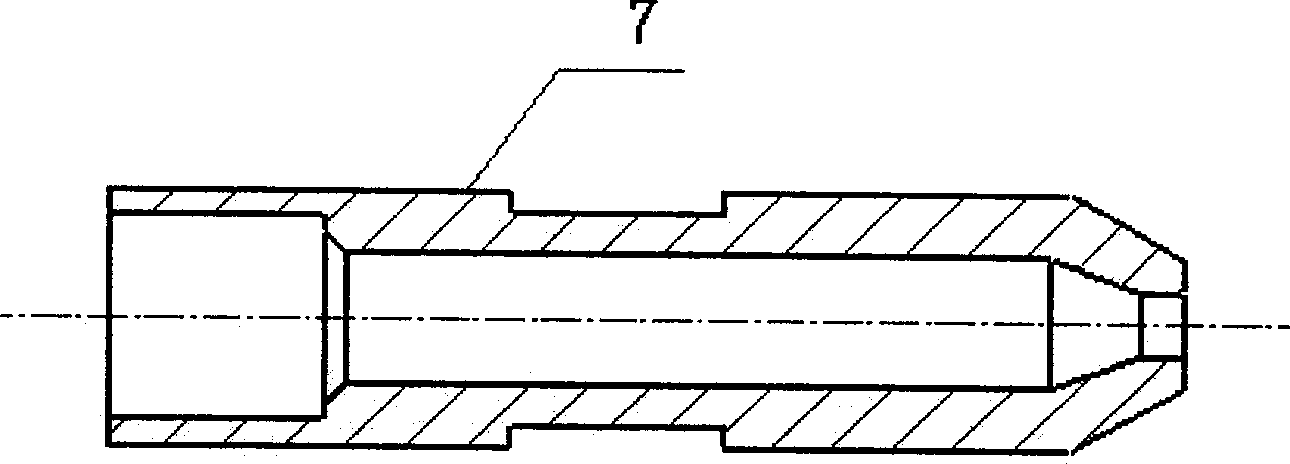

[0027] 3. The high-pressure gas pipe 4 inserted into the catalyst reaction tube adopts one Φ5×8mm polyethylene pipe, and the length is 10m;

[0028] 4. The silver catalyst reaction tube 6 is a steel pipe with an outer diameter of Φ34mm, an inner diameter of Φ28mm, and a length of 10m;

[0029] 5. A vacuum cleaner with two functions of suction and recovery, model CB60-2, is used as suction equipment and recovery filter device;

[0030] 6. One common air valve is used to control the on-off of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com