Transferring device, robot, sorting system and sorting method

A technology of transfer device and sorting system, which is applied in the directions of sorting, storage, transportation and packaging, and can solve the problems of low working efficiency of robots

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

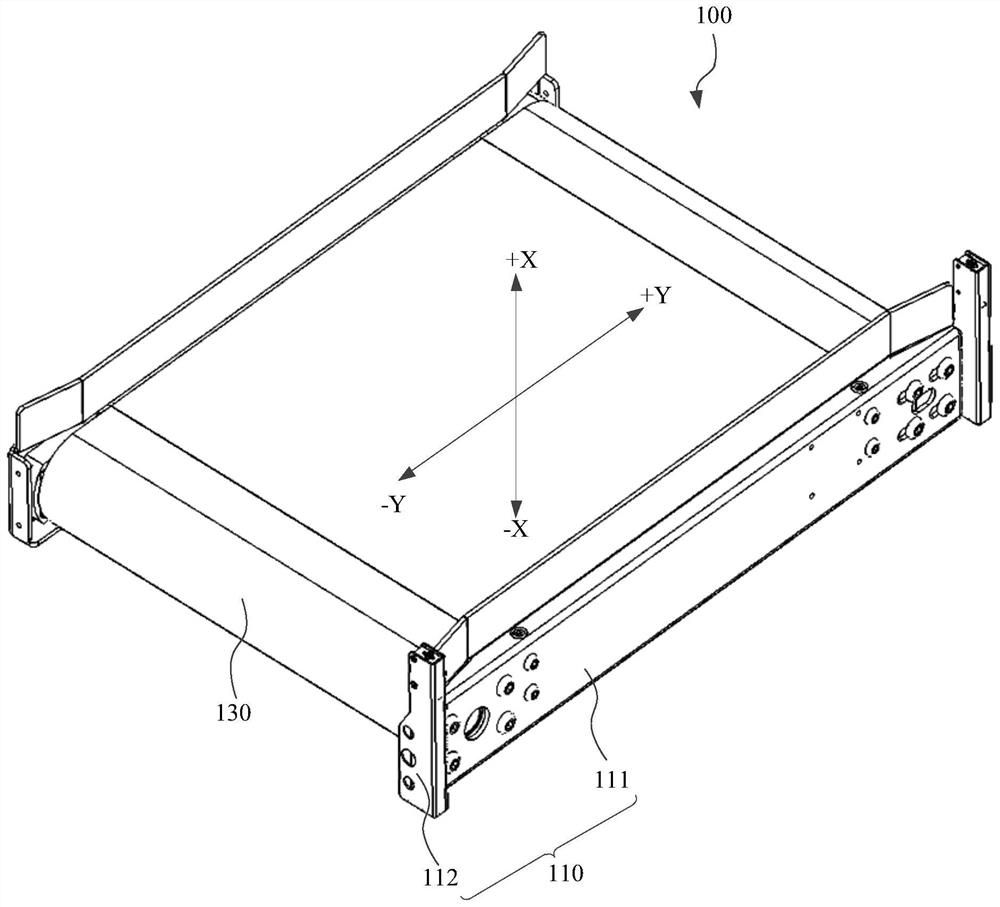

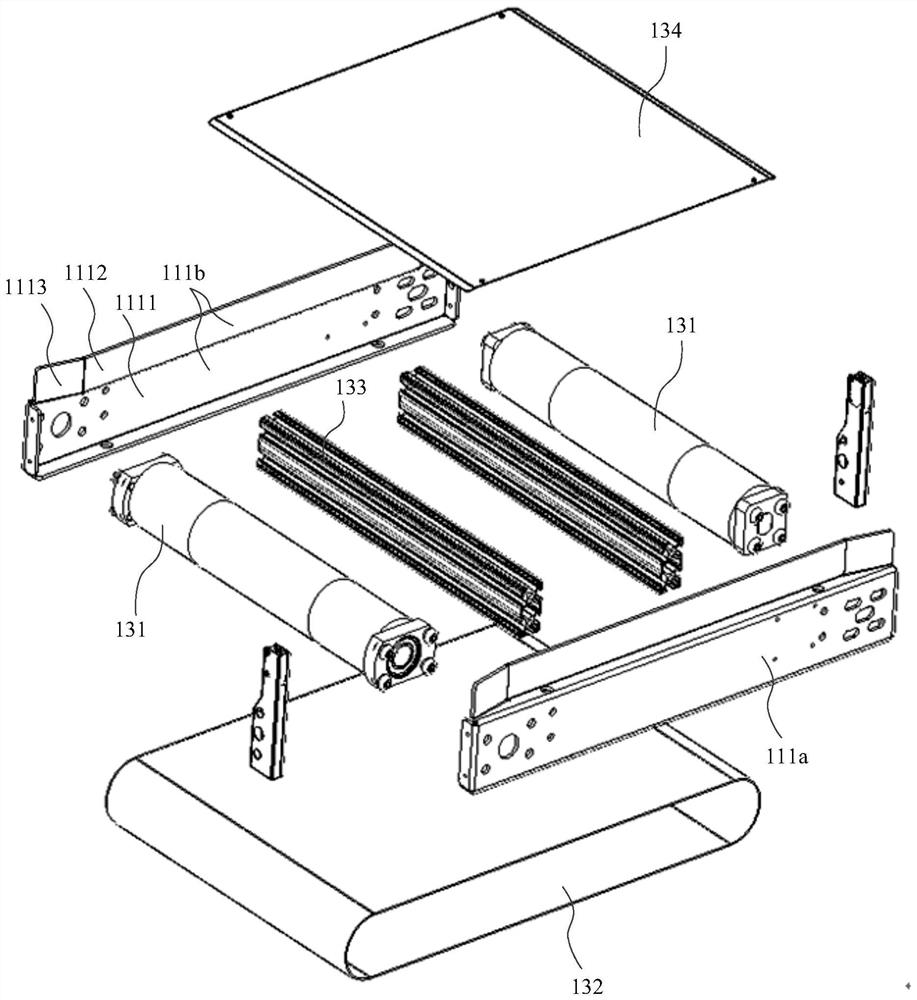

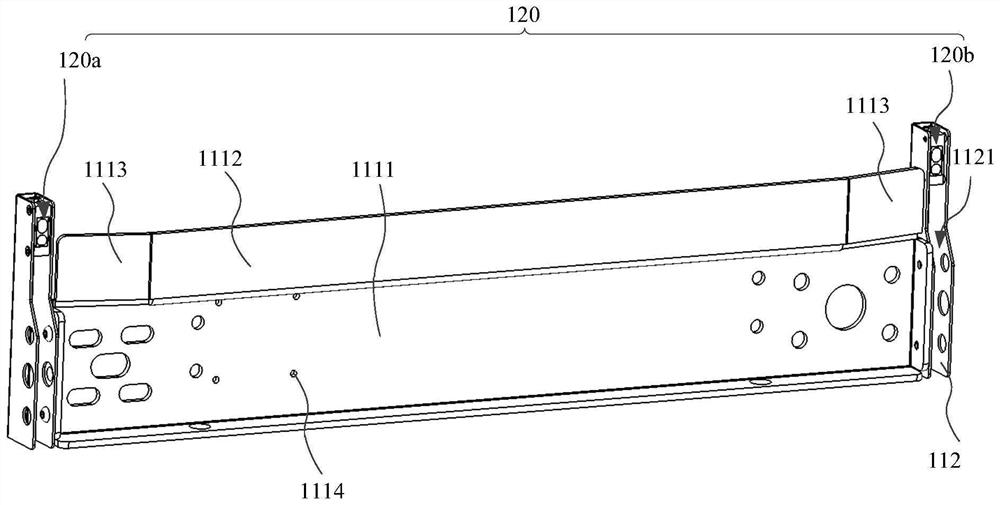

[0108] figure 1 A schematic structural diagram of the transport device provided in the embodiment of the present disclosure; figure 2 An exploded view of the transport device provided by the embodiment of the present disclosure; image 3 A schematic structural diagram of the stent and the detection assembly in the transport device provided in the embodiment of the present disclosure; Figure 4 A schematic structural diagram of a support rod in the transport device provided by the embodiment of the present disclosure; Figure 5 A use state diagram of the transport device provided by the embodiment of the present disclosure; Image 6 for Figure 5 top view of ; Figure 7 A schematic structural diagram of a robot provided by an embodiment of the present disclosure; Figure 8 for Figure 7 Partial enlarged view at A. see Figure 1 to Figure 8 As shown, the present disclosure provides a transfer device 100, which is applied to a device in which a multi-layer turnover box 2...

Embodiment 2

[0135] please continue Figure 1 to Figure 8 As shown, the present disclosure also provides a robot 300, including a body 310 and at least one transfer device 100 disposed on the body 310, where the transfer device 100 is the transfer device 100 provided in any of the above embodiments.

[0136] The structure of the transport device 100 has been described in detail in the above embodiments, and will not be repeated here.

[0137] A pick-up device may also be provided on the robot 300 , and the pick-up device is used to transport the turnover box 200 to the transfer device 100 . Wherein, the pickup device may be a commonly used pickup device, such as a robotic arm, a gripping fork, or a clamping claw, which is not limited in the present disclosure. of this embodiment Figure 7 In the description, the fork 313 is taken as the pickup device.

[0138] In order to facilitate the movement of the robot 300, in a specific implementation, the body 310 includes a first mobile chassis...

Embodiment 3

[0146] Figure 9 Schematic diagram of the structure of the sorting system provided by the embodiment of the present disclosure Figure 1 . see Figure 1 to Figure 9 As shown, the sorting system provided by the present disclosure includes at least one conveyor 400 and at least one robot 300 provided in the above-mentioned embodiments. The conveyor 400 is used to receive the turnover box 200 on the robot 300, or to transfer the turnover box 200 on the conveyor 400. The box 200 is transferred to the robot 300 .

[0147] The structure of the robot 300 has been described in detail in the above embodiments, and will not be repeated here.

[0148] In the following, possible implementation structures of the conveyor 400 will be described through different embodiments.

[0149] Figure 10 Schematic diagram of the structure of the conveyor in the sorting system provided by the embodiment of the present disclosure Figure 1 ; Figure 11 for Figure 10 Schematic diagram of the int...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com