Continuous nut tapping device with function of bidirectional feeding

A technology of bidirectional feeding and tapping device, which is applied to positioning device, clamping device, thread tangent device, etc., can solve the problems of long time interval between continuous tapping, inability to realize continuous tapping, and time-consuming, etc. Feeding and tapping intervals, manufacturing cost savings, innovative design effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

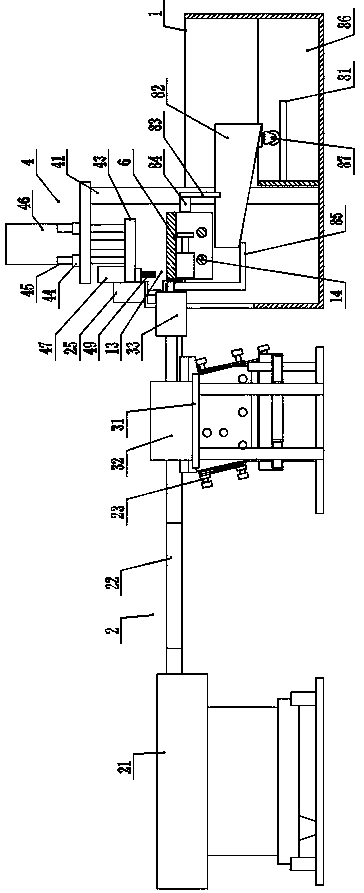

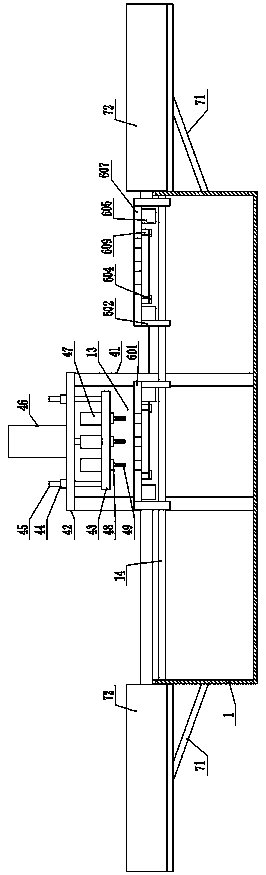

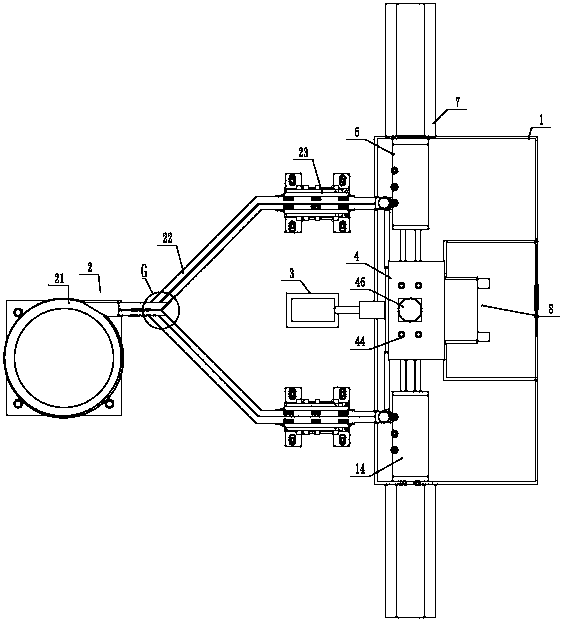

[0033] The present invention will be specifically described below in conjunction with the accompanying drawings, such as Figure 1-13Shown: a two-way feeding nut 5 continuous tapping device, comprising a frame 1, a double-track feeding mechanism 2, a nut pressing mechanism 3 and a tapping mechanism 4, and there are two feeding stations 11 in the frame 1, The two to-be-processed stations 12 located between the two loading stations 11 and the tapping station 13 located between the two to-be-processed stations 12, the two output ends of the dual-track feeding mechanism 2 extend to the two upper Material station 11, two horizontally arranged sliding rods 14 are fixed in the frame 1, and two nut carrying mechanisms 6 for carrying nuts 5 are slidably installed on the sliding rods 14, and each nut carrying mechanism 6 is in the same position. The feeding station 11 on the side, the station to be processed 12 on the same side and the tapping station 13 are active, and two linear drivi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com