Transportation system, loading method and unloading method suitable for cold chain logistics container

A transportation system and cold chain logistics technology, which is applied in the transportation, transportation and packaging of refrigerated goods, and transported objects, etc., can solve the problems of difficulty in guaranteeing the quality of cold chain logistics items, large air area of refrigerated goods, and health hazards of workers, etc. To achieve the effect of reducing the damage of containers and commodities, thawing and refreezing problems, saving transportation time, and saving logistics costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

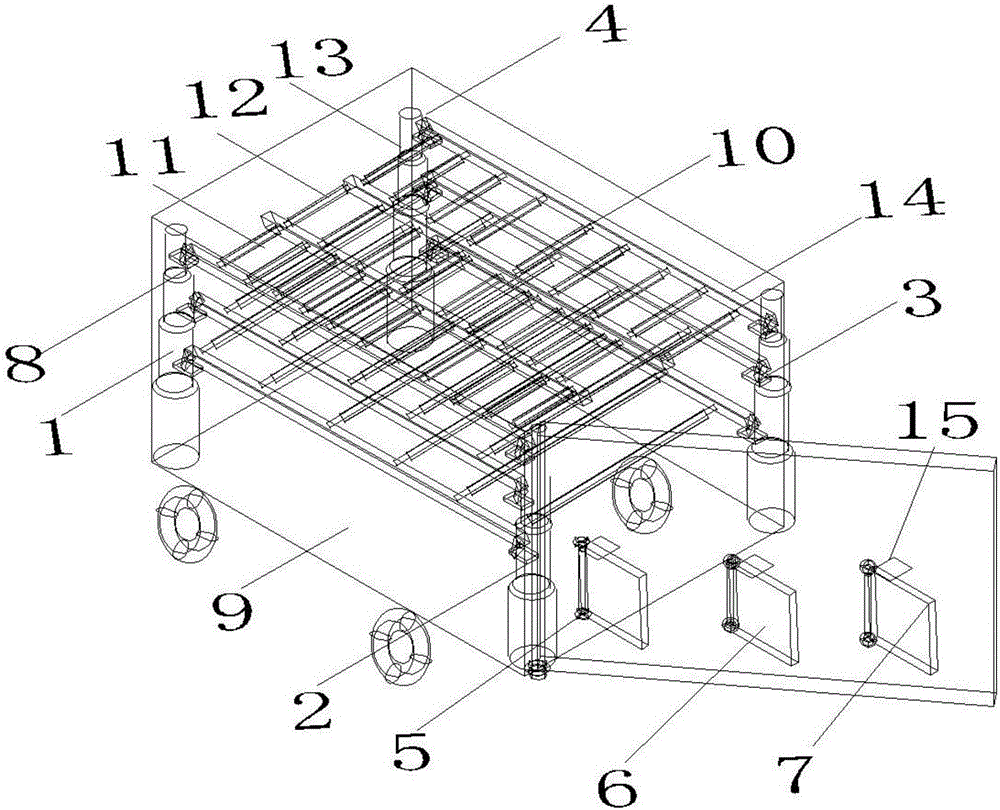

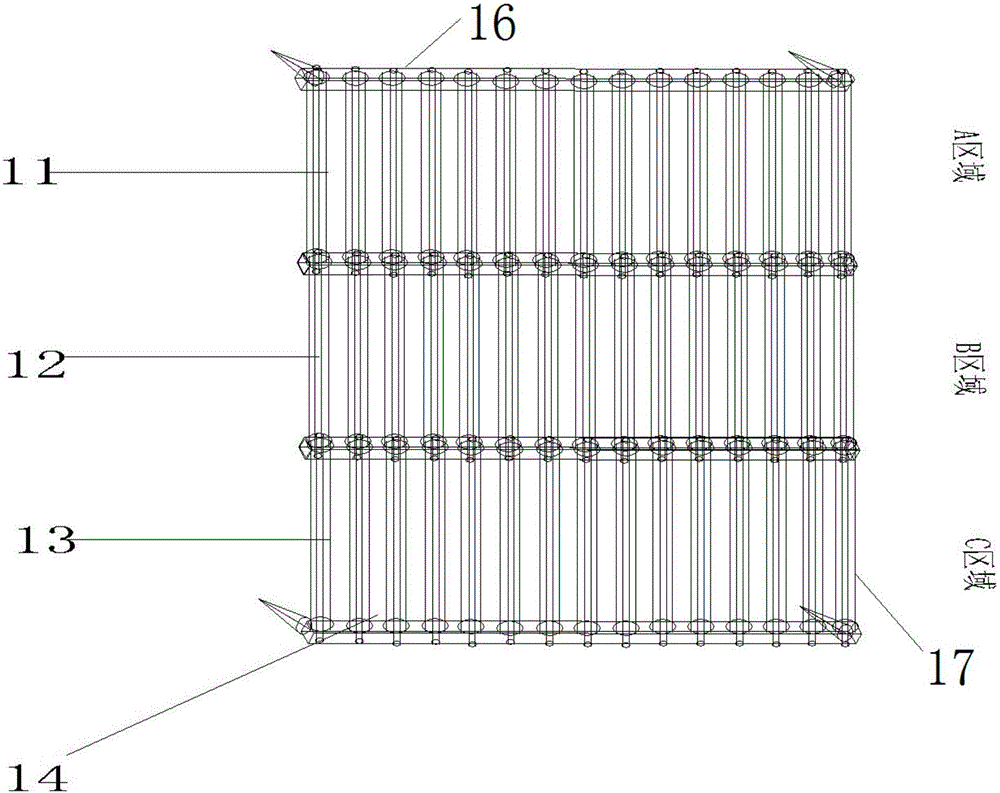

[0042] like figure 1 As shown in the figure, a transportation system suitable for cold chain logistics cargo boxes is mainly composed of a lifting device, a layered rolling rack, a small delivery door, a standard cargo box and a power system. Each of the four corners of the bottom 9 of the refrigerated compartment is erected with a hydraulic support, which is divided into a plurality of rectangular supports. The top of the refrigerated compartment is provided with a compartment roof 10, which protects the lifting device, the layered rolling rack, the small delivery door, the standard cargo box and the power system therein.

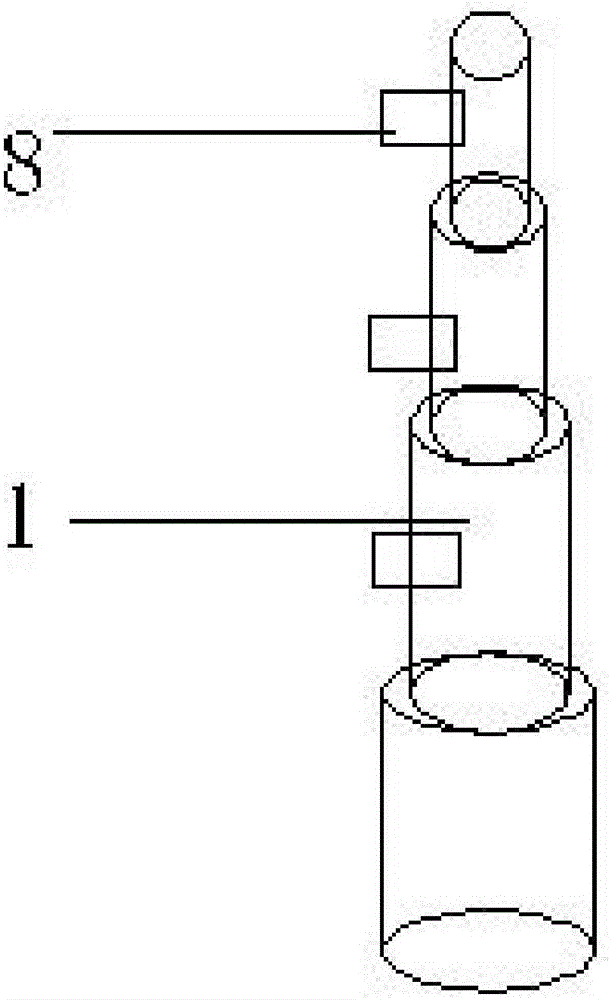

[0043] like figure 2 As shown in the figure, the lifting device is supported by the hydraulic pillars at the four corners of the carriage, including the rack hydraulic axis I1, the rack hydraulic axis I2, the rack hydraulic axis ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com