Method for operating a D.C. generator

A technology of DC motor and DC power supply, which is applied to the starter of a single DC motor, the deceleration device of an AC motor, and the motor start of an engine, etc. It can solve the problems of reduced efficiency, over-thick coating, damage, etc., and can improve the service life , easy-to-obtain effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

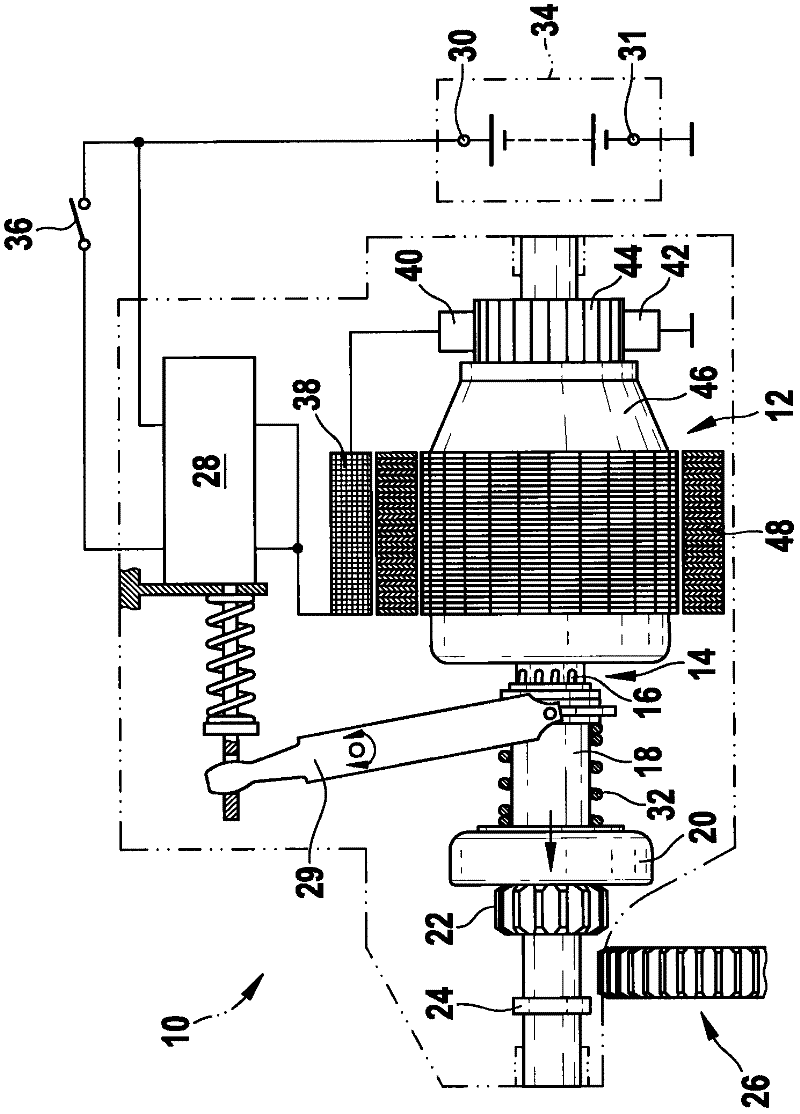

[0016] figure 1 The mechanical structure of a DC electric machine embodied as a displacement-screw starter for an internal combustion engine is schematically shown. The starter 10 has a starter motor 12 , the driven shaft 14 of which has a multi-start thread 16 which interacts with a corresponding nut thread in a drive rod 18 . Alternatively, the driven shaft 14 is driven via an interposed planetary gear, not shown. The driving rod 18 is fixedly connected with the outer ring of the free rolling ring 20 , the inner ring of which supports the pinion 22 . The pinion 22 and the free-running ring 20 are mounted on the output shaft 14 so as to be axially displaceable up to a stop 24 . The pinion 22 meshes here with a ring gear 26 of the internal combustion engine, not shown. by means of Figure 5 with 6 Axial movement is effected by a relay device 28 shown in detail in , which is engaged on the free-running ring 20 via a deflection rod 29 and an engaging spring 32 . A battery ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com