Wall-scrapping type high-speed disperse mixer

A high-speed dispersion and mixer technology, which is used in mixer accessories, mixers with rotary stirring devices, mixers, etc., can solve the problems of inability to quickly disperse solid-phase materials, long discharge time for large-volume stirring tanks, and achieve a simple structure. , fast speed, improve the effect of uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further elaborated below in conjunction with the accompanying drawings.

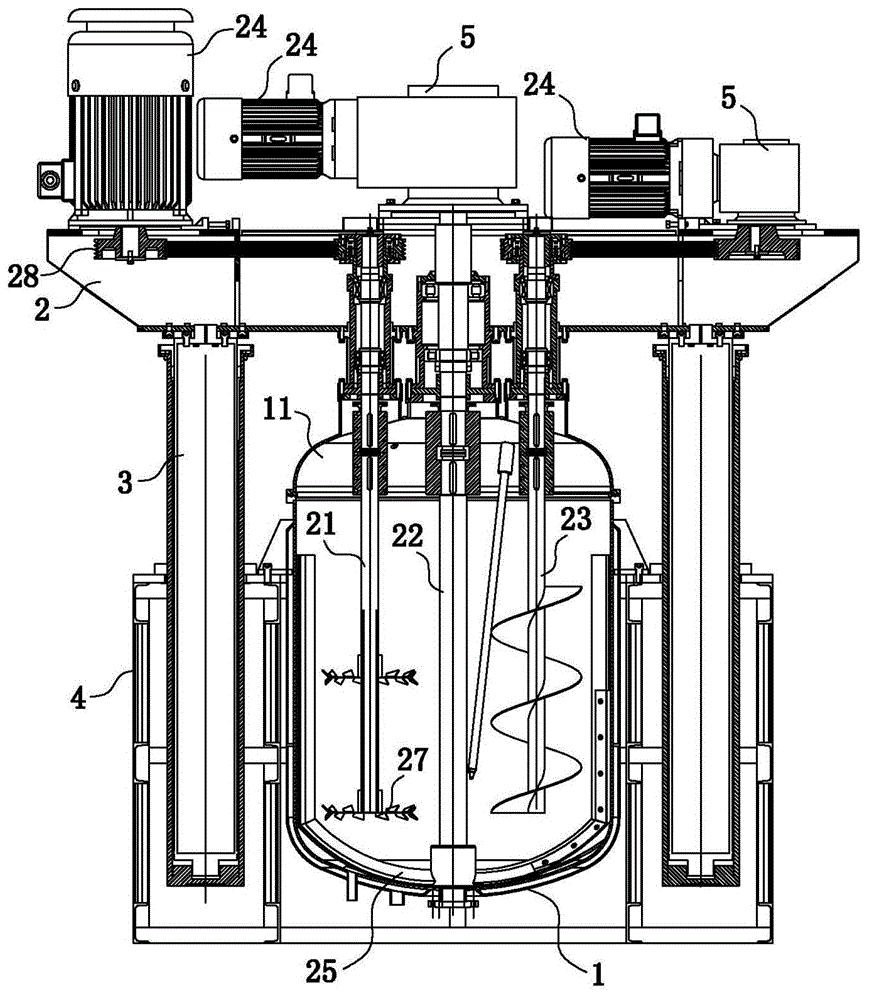

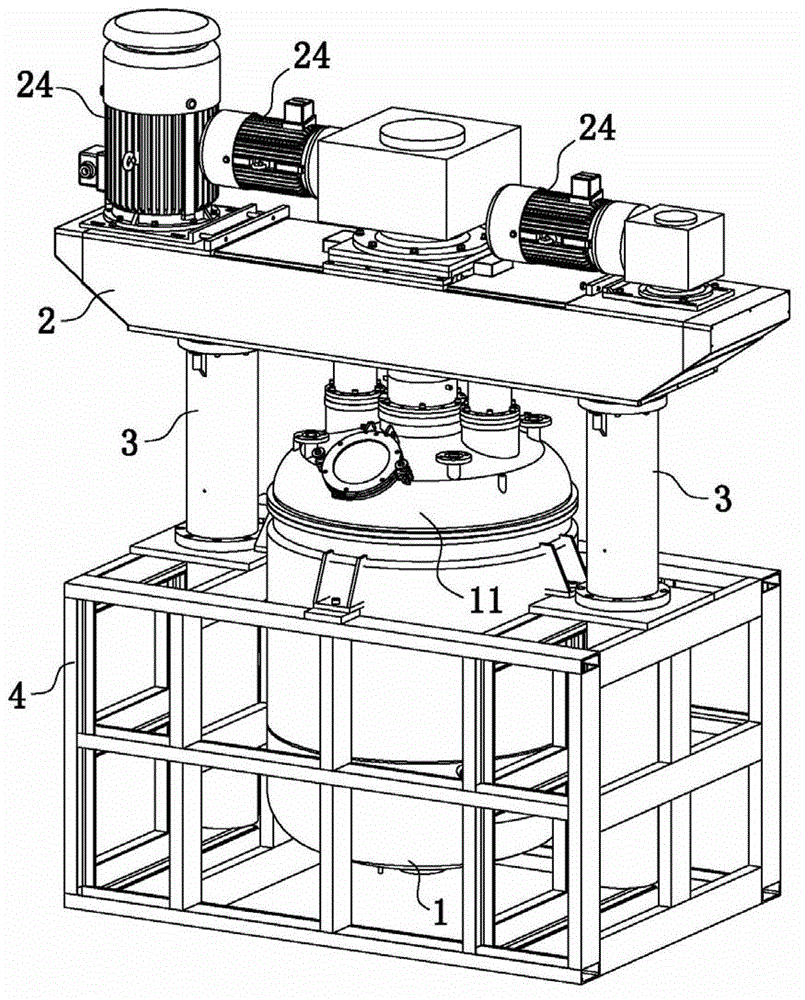

[0020] refer to figure 1 As shown, one embodiment of the present invention is a scraping-type high-speed dispersion mixer, comprising a kettle body 1 and a stirring device 2 installed above the kettle body 1, and the stirring device 2 includes a high-speed shaft 21 and a medium-speed shaft 22 , the low-speed shaft 23 and the motor 24, the tops of the high-speed shaft 21, the medium-speed shaft 22 and the low-speed shaft 23 are respectively connected with the motor 24 output shaft power, and the high-speed shaft 21, the medium-speed shaft 22 and the low-speed shaft 23 pass through the kettle cover 11 Extend into the inner cavity of the kettle body 1; and at least one tooth-shaped dispersing disc 27 needs to be installed on the high-speed shaft 21, and a frame-type agitator 25 needs to be installed on the lower end of the low-speed shaft 23. However, in this embodiment...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com