Slag-salvaging stirring machine

The technology of a mixer and a slag scoop is applied in the field of metal smelting auxiliary equipment, which can solve the problems of large metal loss, large amount of slag, low safety, etc., and achieve the effects of smooth automatic lifting, less metal entrained in the slag, and improved production efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with the accompanying drawings and embodiments. It should be noted that the specific embodiments of the present invention are only for the purpose of describing the technical solution more clearly, but not as a limitation of the protection scope of the present invention.

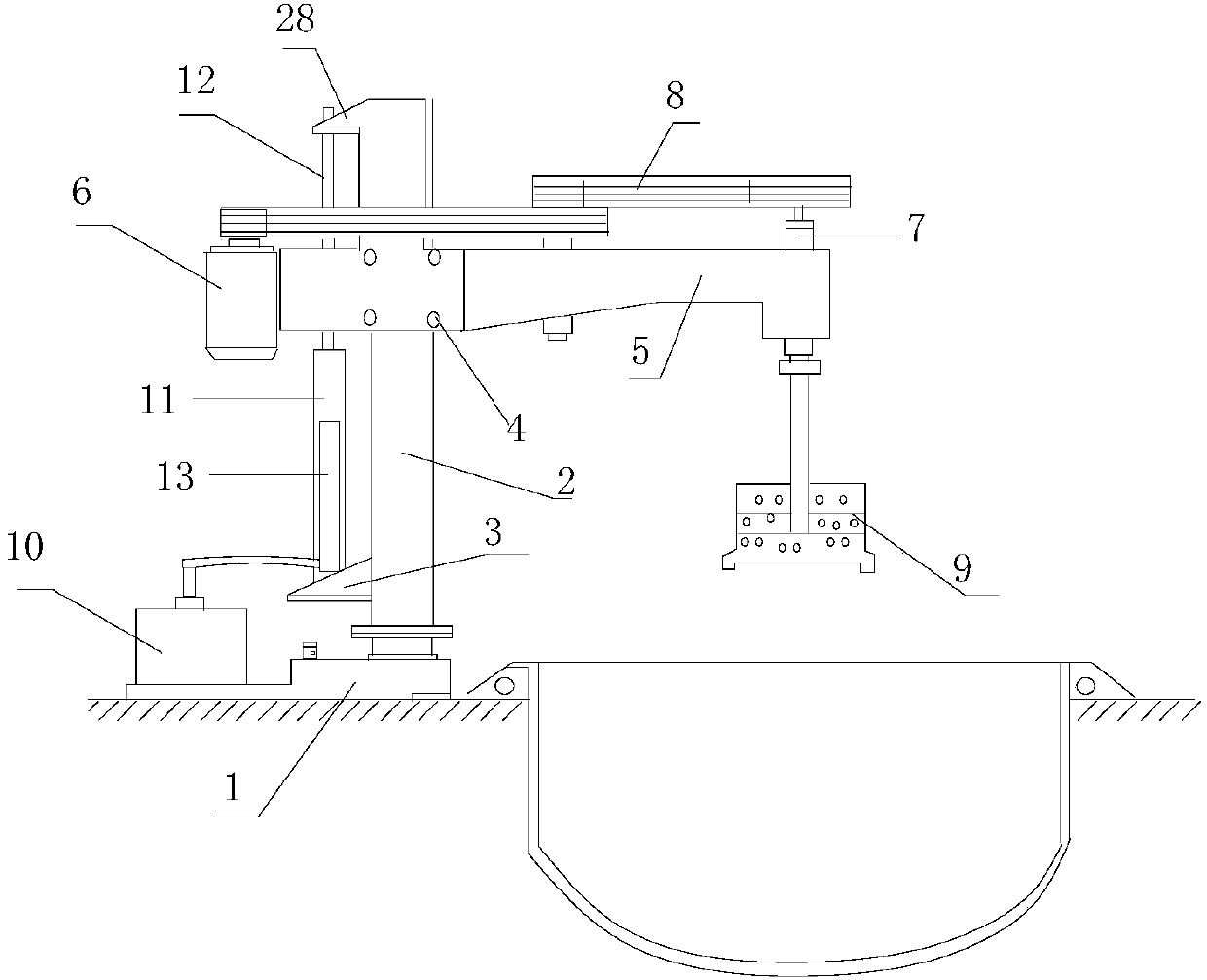

[0026] see figure 1 , a slag removal mixer, which is installed next to a high-temperature furnace, includes a base 1, a lifting mechanism and a working cantilever,

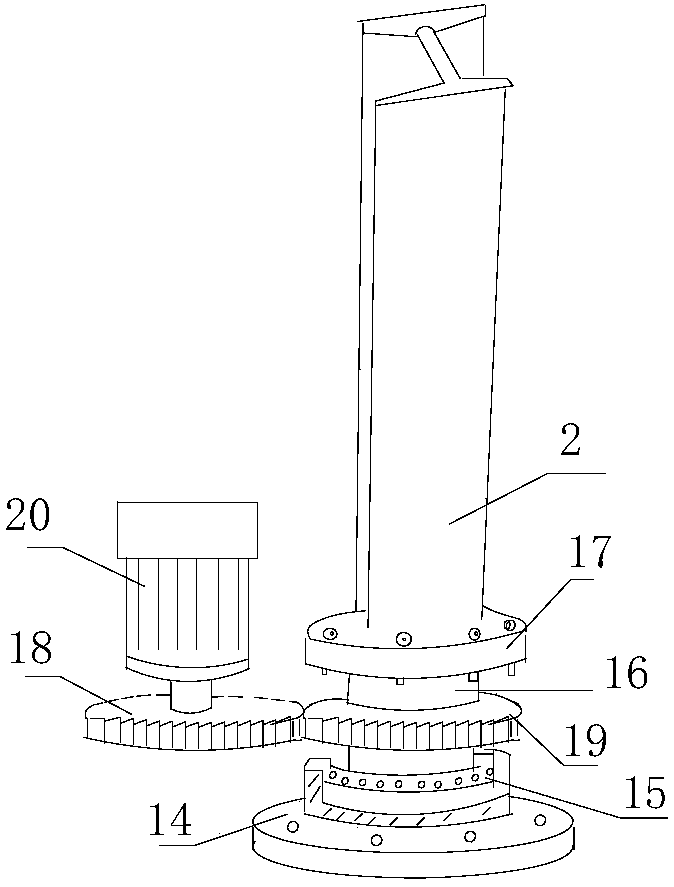

[0027] The base 1 includes a rotating mechanism for horizontally rotating the lifting mechanism;

[0028] The lifting mechanism includes a main body guide post 2 and a hydraulic push rod, the main body guide post 2 is connected to the base 1, the main body guide post 2 is provided with a hydraulic rod base, and the hydraulic push rod is arranged on On the hydraulic push rod base, the lifting mechanism is used to lift the working boom;

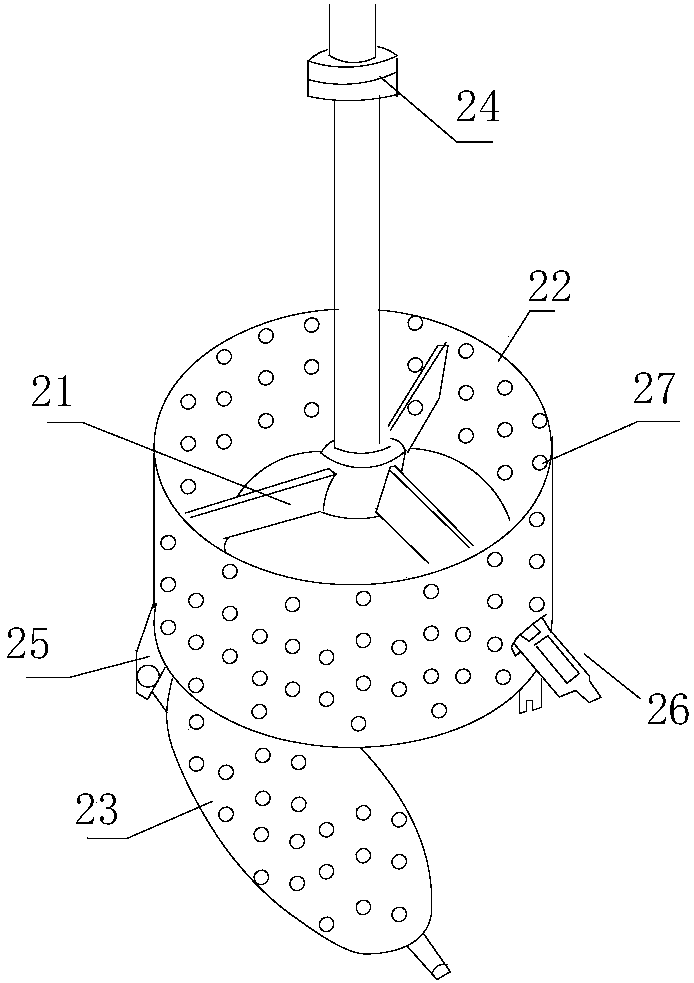

[0029] The working cantilever i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com