Easy-to-unload type concrete stirring device

A mixing device and concrete technology, which is applied in the direction of unloading device, cement mixing device, clay preparation device, etc., can solve the problems of low mixing efficiency and slow unloading, achieve good mixing effect and speed up mixing speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

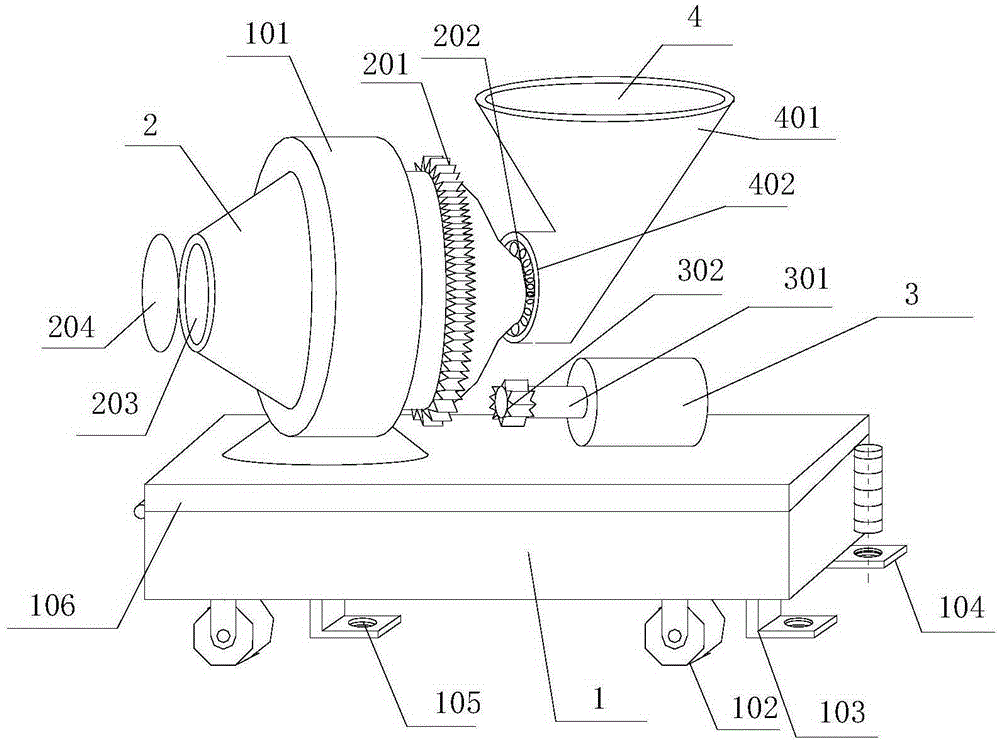

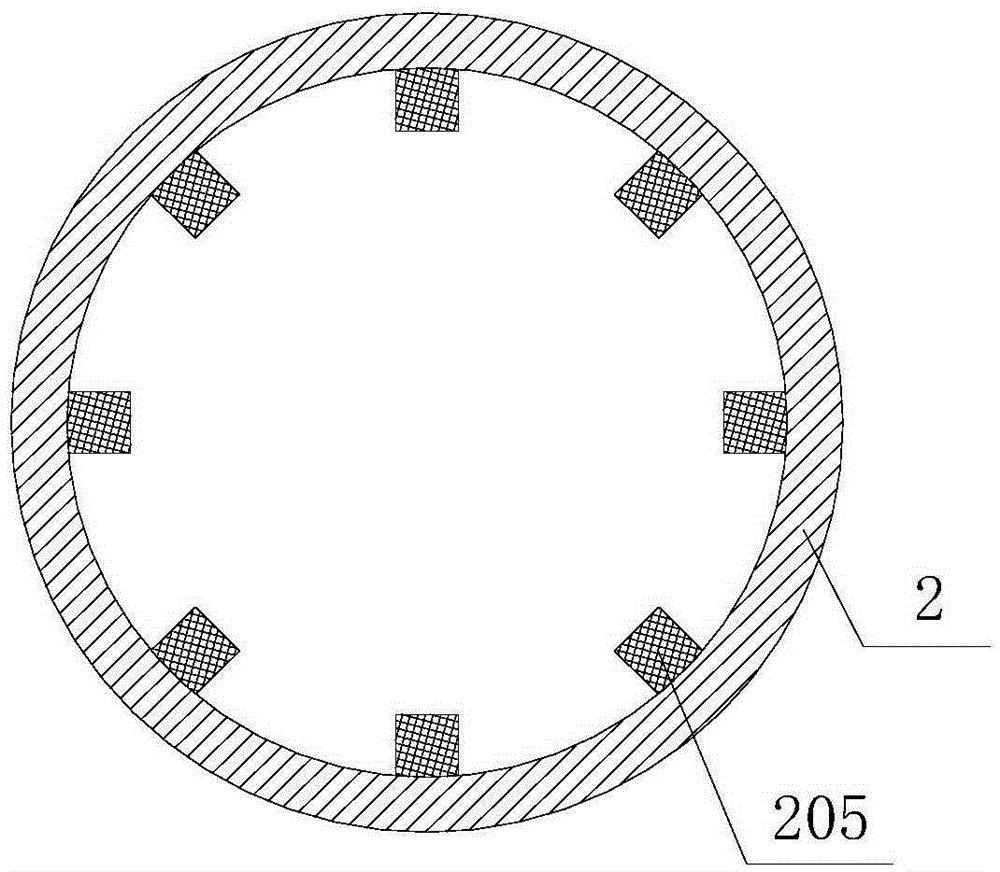

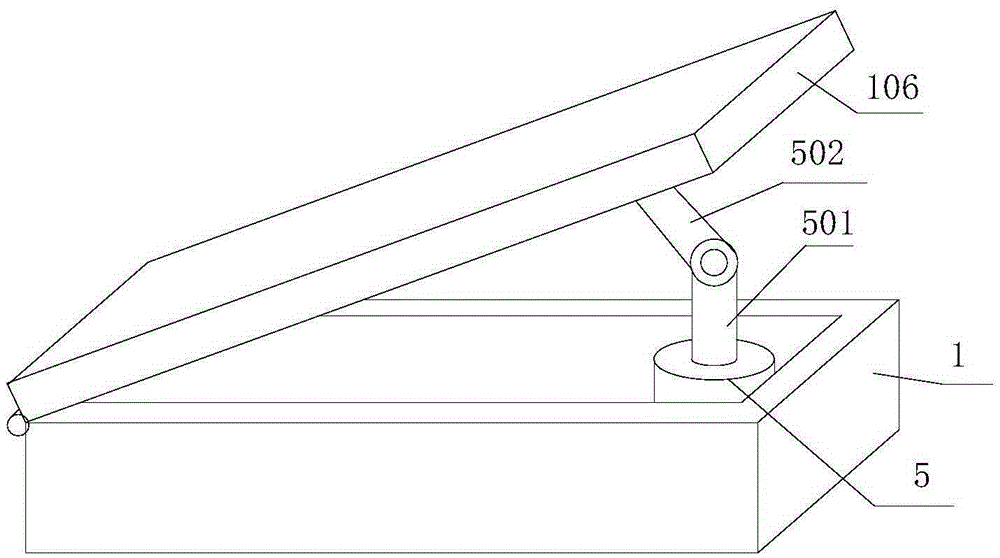

[0021] Such as Figure 1-Figure 3 , an easy-unloading concrete mixing device, including a frame 1, a mixing tank 2 and a motor 3, the mixing tank 2 is cylindrical, and the mixing tank 2 is placed on the frame 1 in a side position, and it passes through the first roller 101 It can be rotatably installed on the frame 1, and the stirring tank 2 is provided with a ring gear 201 around its barrel, and the end of the crankshaft 301 of the motor 3 is provided with a gear 302 matched with the ring gear 201, so One end of the mixing tank 2 is provided with a feeding port 202, and the other end is provided with a feeding port 203, and a feeding device 4 is provided at the feeding port of the mixing tank 2, and the feeding device 4 includes a hopper 401 and a second roller 402, The hopper 401 is fixedly connected to the second roller 402, and the second roller 402 is movably connected to the mixing tank 2. A closed door 204 is provided at the discharge port 203, and a wall along the side...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com