Self-unloading bulk cargo transport ship and unloading method thereof

A technology of transport ships and cargo warehouses, applied in the field of ships, can solve the problems of small warehouse volume, difficult maintenance, low self-unloading efficiency, etc., and achieve the effect of high warehouse capacity utilization, simple structure and high unloading efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0053] The present invention will be further described below in conjunction with specific embodiments.

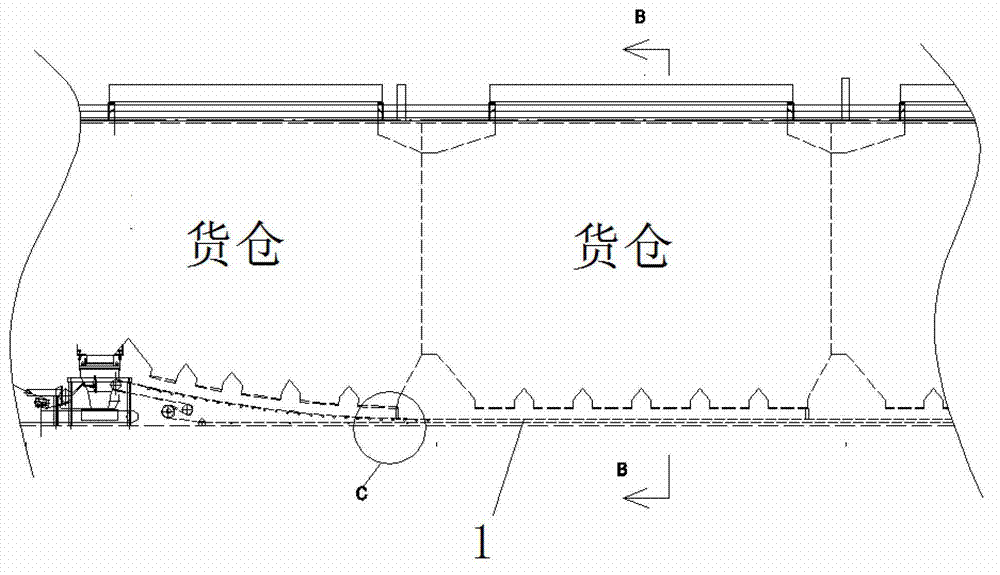

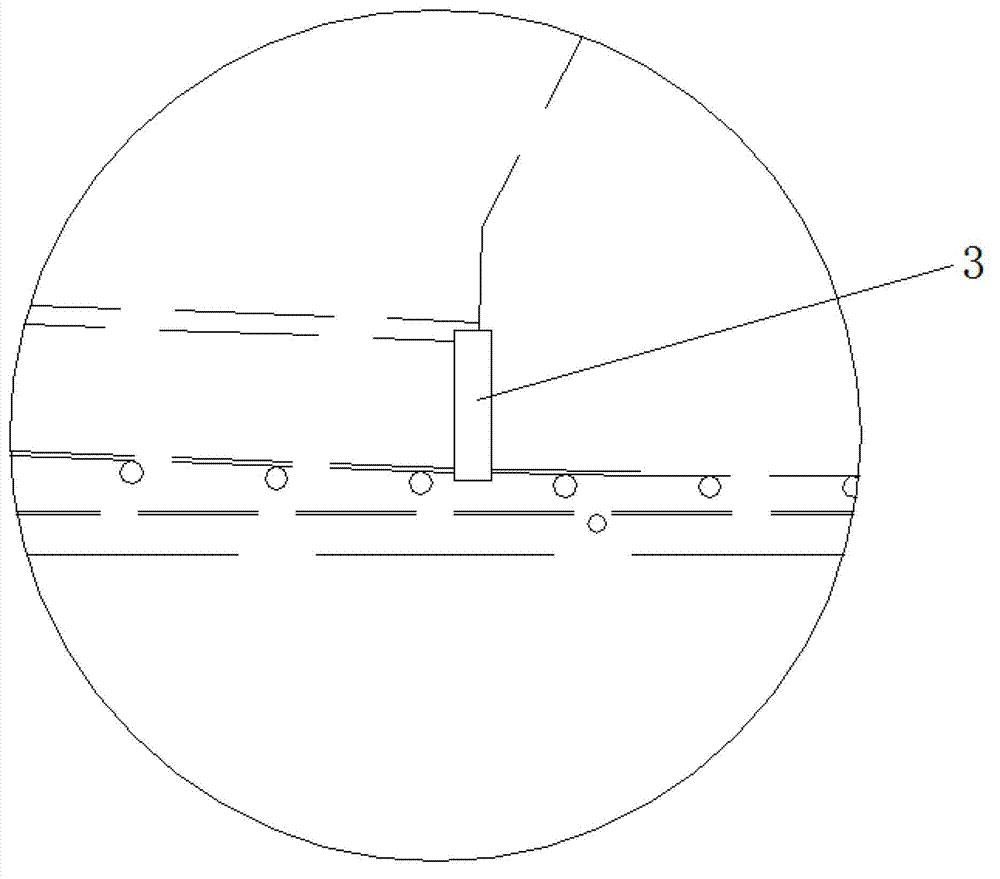

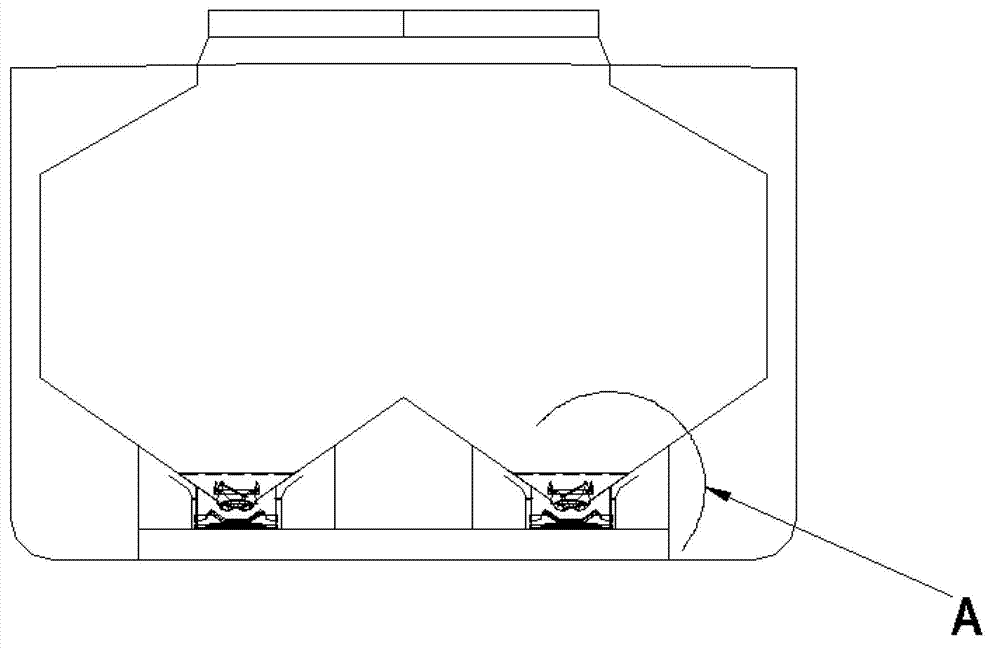

[0054] A self-unloading bulk cargo carrier includes five marine cranes 6, the marine crane 6 is arranged above the deck, and a warehouse grab 601 is arranged on it; the hull deck is equipped with a one-to-one correspondence with each marine crane Deck hopper 5, deck hopper 5 is set on the starboard side. Below it is a longitudinal conveyor belt 4, which is arranged longitudinally along the hull and above the cargo warehouse; the tail of the longitudinal conveyor belt 4 is provided with a first discharge port, The first discharge port corresponds to the horizontal conveyor belt, which is arranged horizontally along the hull, connecting the starboard side of the deck and the port side of the deck; a second discharge port is provided at the tail of the horizontal conveyor belt, and the second discharge port corresponds to the inclined conveyor belt 7. , The inclined conveyor belt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com