Novel unloading platform

A platform and new technology, applied in the field of unloading platform and logistics equipment manufacturing, to achieve the effect of fast unloading speed, high unloading efficiency and strong practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

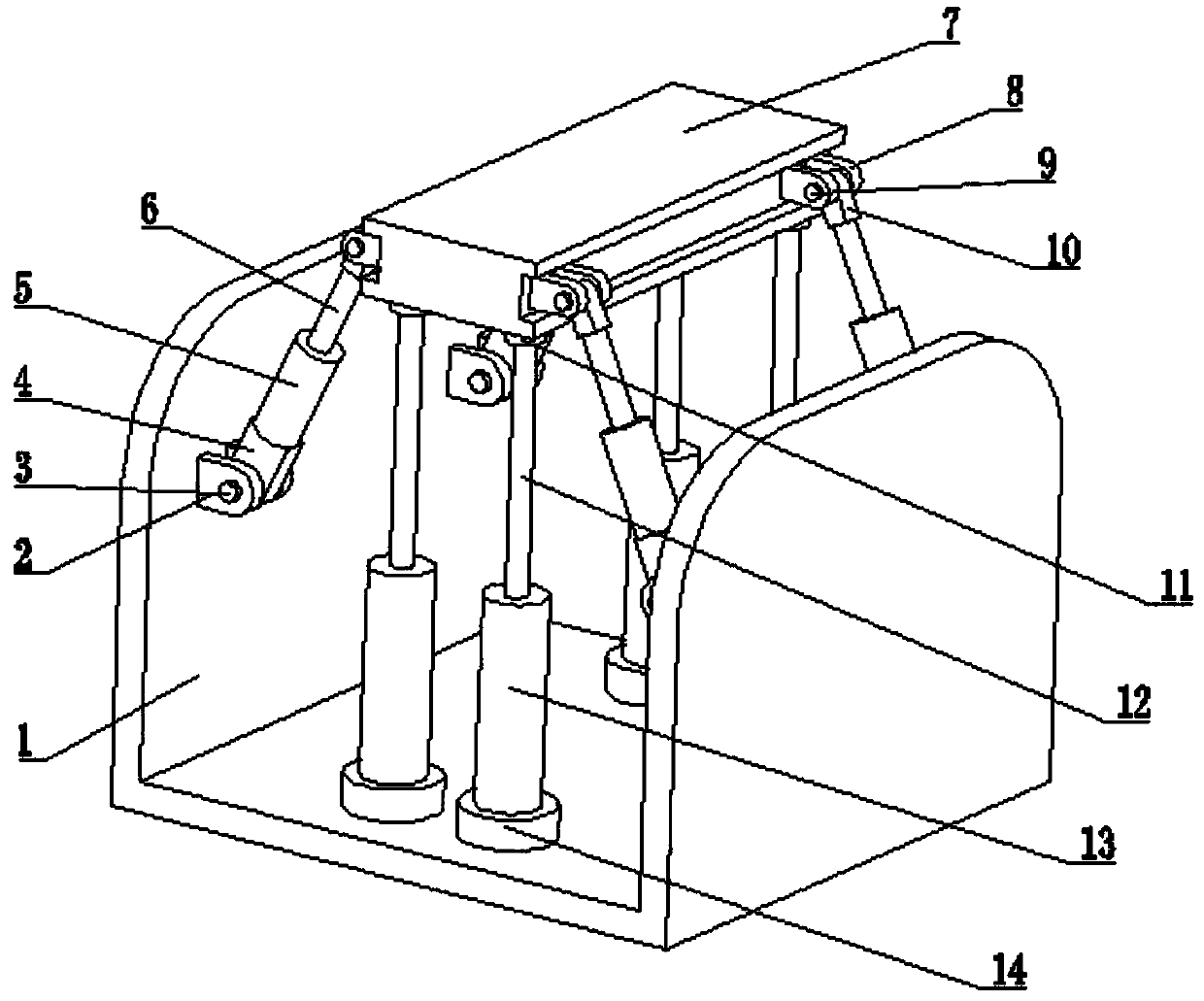

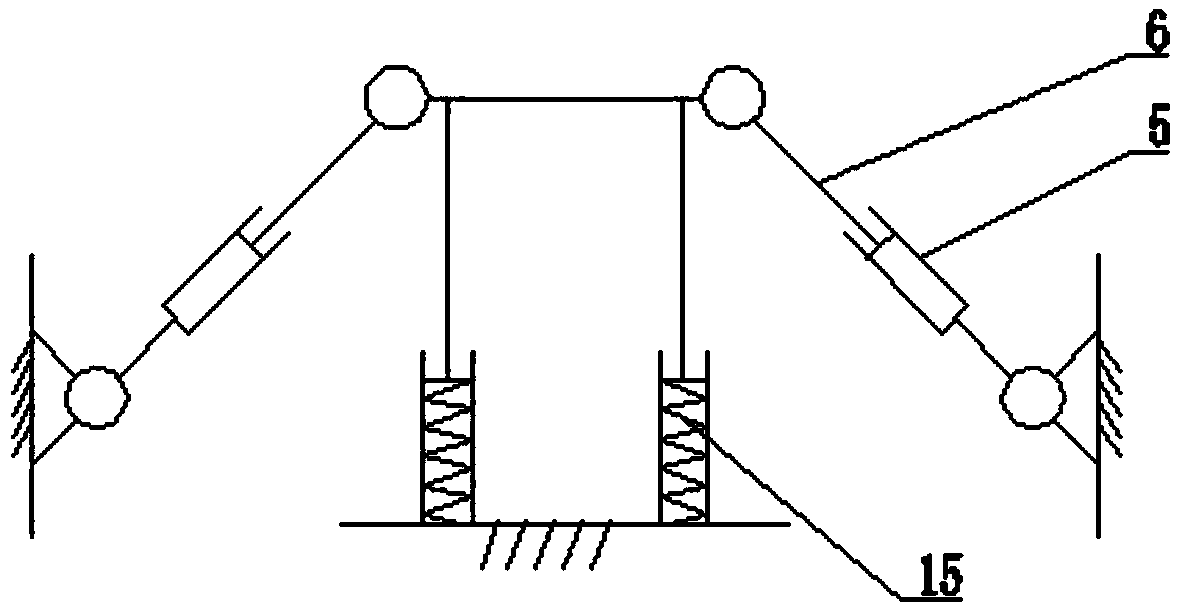

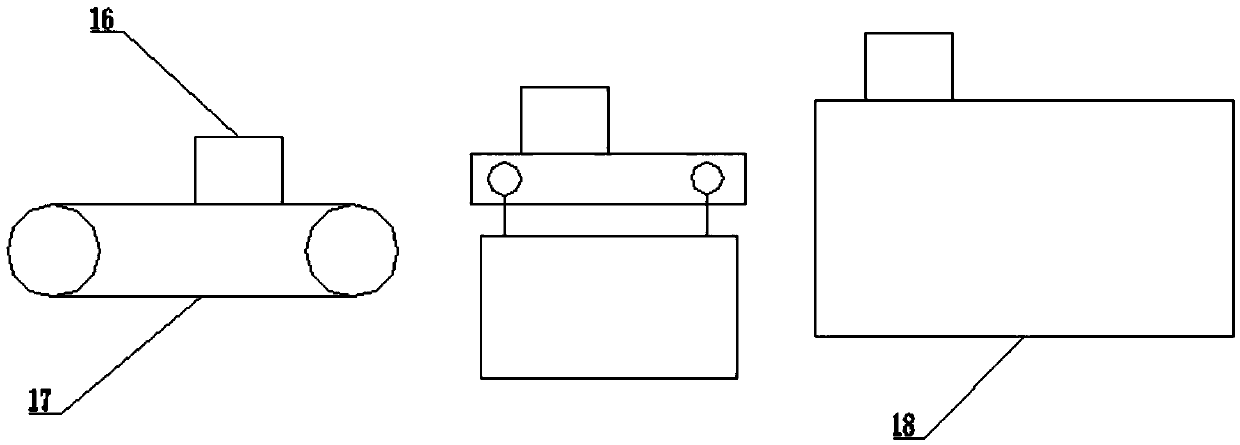

[0017] refer to figure 1 , figure 2 with image 3 , a new type of unloading platform in the present invention, including a base 1, a first hinged bracket 2, a first hinged rod 4, a first main rod 5, a first slide rod 6, a storage board 7, a second hinged bracket 8, a second hinged Rod 10, the second slide bar 12, the second main rod 13 and the spring 15, the base 1 is made into a U-shaped structure, the base 1 includes a base plate and two side plates; the base plate of the base 1 is equipped with several first Two positioning blocks 14, several first hinged brackets 2 are installed on the side plate of the base 1; the first hinged bracket 2 is connected with the first hinged rod 4 by the first pin 3, and the first hinged rod 4 is connected with the first main rod 5 is fixedly connected; the second hinged bracket 8 is connected to the second hinged rod 10 by the second pin 9, and the second hinged rod 10 is fixedly connected with the first slide bar 6; the second positionin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com