Container vehicle hopper used for mine-use electric locomotive and capable of quickly and thoroughly unloading

A technology of container trucks and electric locomotives, which is applied in mining vehicles, transport buses, transportation and packaging, etc., and can solve the problems of low unloading efficiency, incomplete unloading and residual, slow unloading speed, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

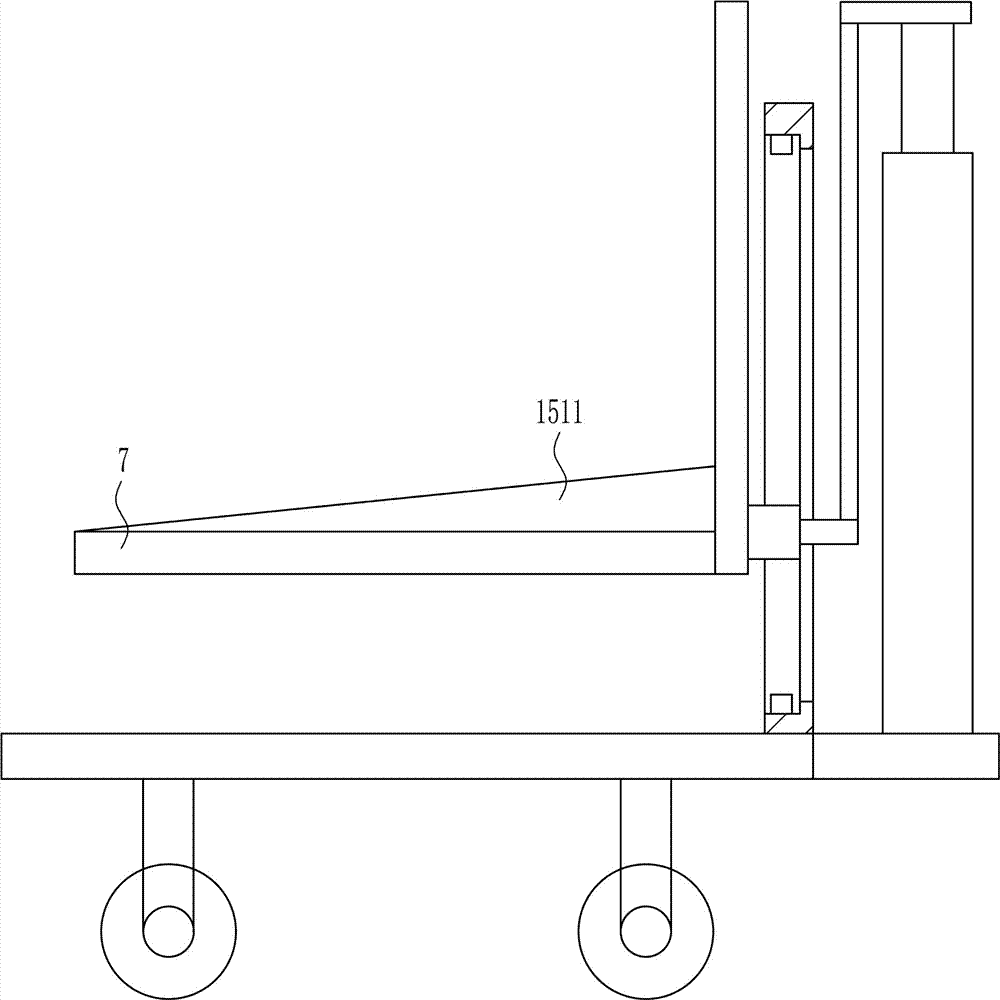

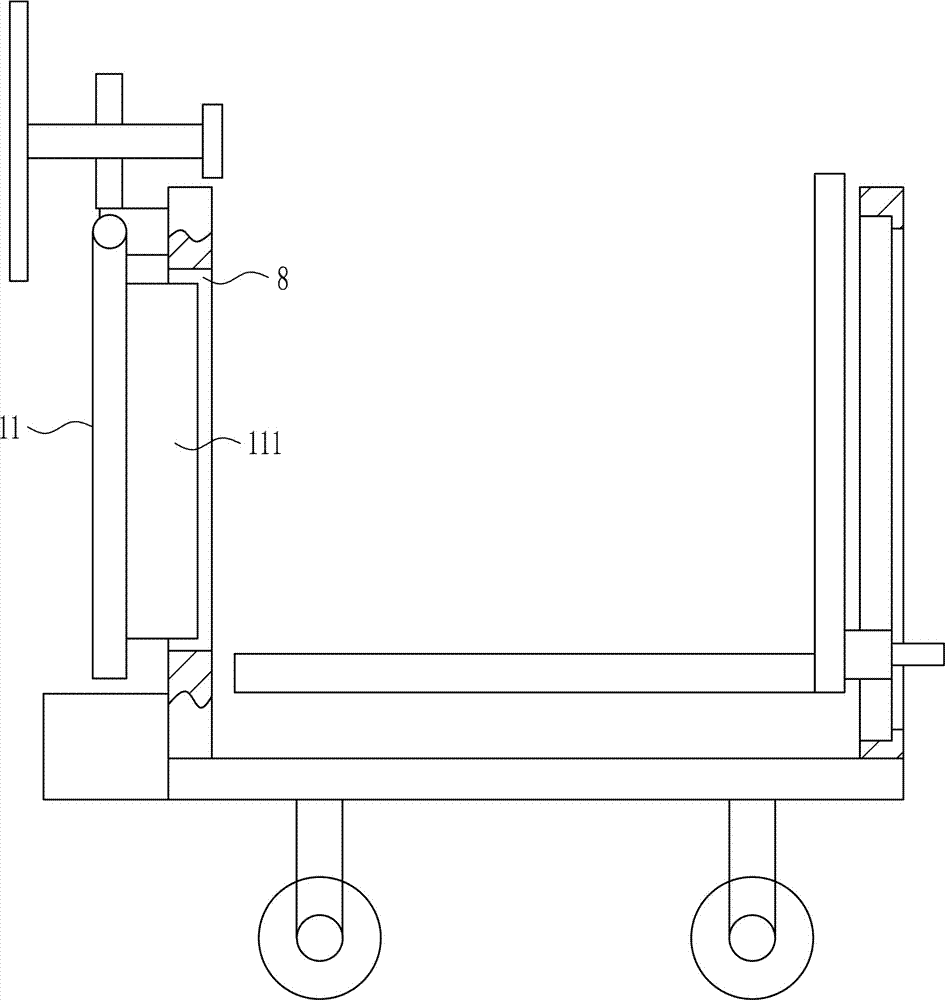

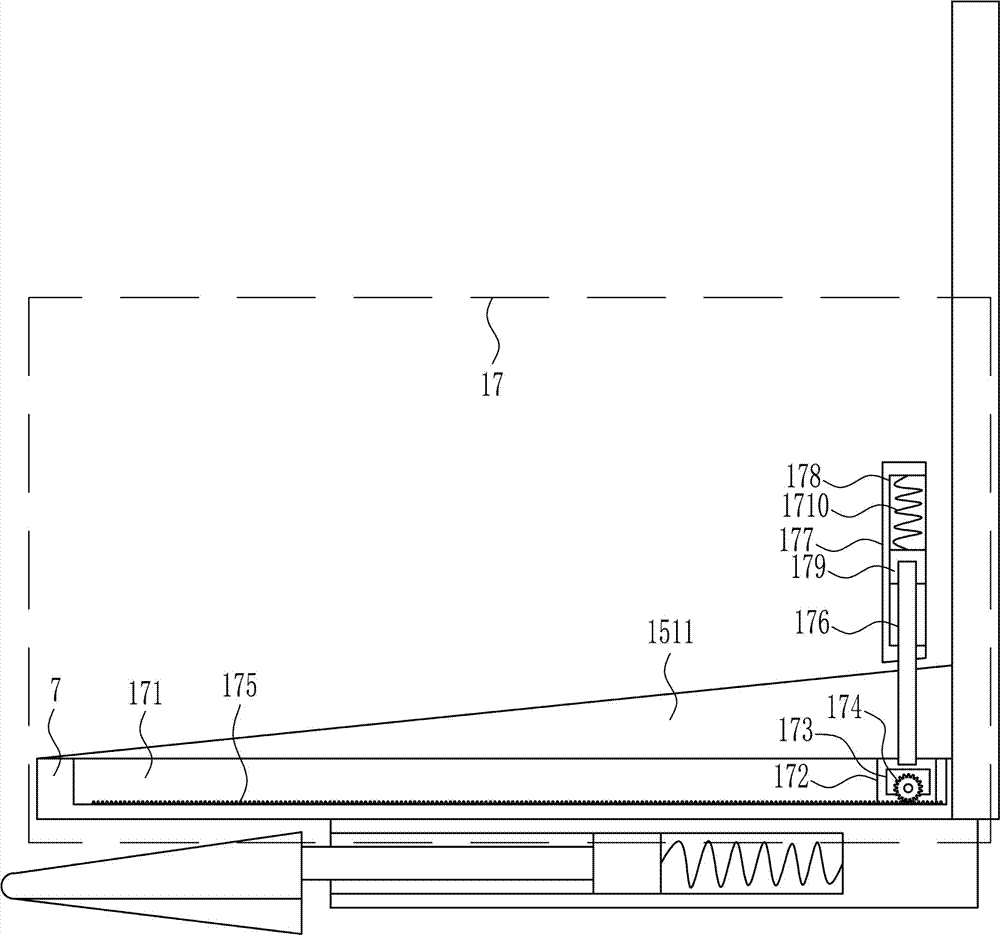

[0038] A container body for mining electric locomotives capable of quick and complete unloading, such as Figure 1-8 As shown, it includes a container bucket 1, a first slide rail 2, a first slider 3, a handle 5, a push plate 6, a placement plate 7, a support seat 9, a first rotating shaft 10, a cover plate 11, and a first nut 12. The first screw rod 13 and the pressure plate 14, the first slide rail 2 is installed in the right side wall of the container bucket 1 by means of bolt connection, the first slide rail 2 is slidably connected with the first slide block 3, the assembly There is a word hole 4 on the right side wall of the car body 1, and a handle 5 is installed on the right side of the first slider 3 by welding. The handle 5 extends to the right side of the container body 1 through the word hole 4, and the first slider 3 A push plate 6 is installed on the left side by welding, a placement plate 7 is installed on the lower left side of the push plate 6 by welding, a rec...

Embodiment 2

[0040] A container body for mining electric locomotives capable of quick and complete unloading, such as Figure 1-8 As shown, it includes a container bucket 1, a first slide rail 2, a first slider 3, a handle 5, a push plate 6, a placement plate 7, a support seat 9, a first rotating shaft 10, a cover plate 11, and a first nut 12. The first screw rod 13 and the pressure plate 14, the first slide rail 2 is installed in the right side wall of the container bucket 1 by means of bolt connection, the first slide rail 2 is slidably connected with the first slide block 3, the assembly There is a word hole 4 on the right side wall of the car body 1, and a handle 5 is installed on the right side of the first slider 3 by welding. The handle 5 extends to the right side of the container body 1 through the word hole 4, and the first slider 3 A push plate 6 is installed on the left side by welding, a placement plate 7 is installed on the lower left side of the push plate 6 by welding, a rec...

Embodiment 3

[0043] A container body for mining electric locomotives capable of quick and complete unloading, such as Figure 1-8 As shown, it includes a container bucket 1, a first slide rail 2, a first slider 3, a handle 5, a push plate 6, a placement plate 7, a support seat 9, a first rotating shaft 10, a cover plate 11, and a first nut 12. The first screw rod 13 and the pressure plate 14, the first slide rail 2 is installed in the right side wall of the container bucket 1 by means of bolt connection, the first slide rail 2 is slidably connected with the first slide block 3, the assembly There is a word hole 4 on the right side wall of the car body 1, and a handle 5 is installed on the right side of the first slider 3 by welding. The handle 5 extends to the right side of the container body 1 through the word hole 4, and the first slider 3 A push plate 6 is installed on the left side by welding, a placement plate 7 is installed on the lower left side of the push plate 6 by welding, a rec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com