Hydraulic lifting device capable of automatically dropping and automatic pile dropping method thereof

A hydraulic lifting device and self-lowering technology, which is applied in the field of marine engineering, can solve the problems of slow pile-down speed, easily damaged bolts, energy consumption, etc., and achieve the effect of fast pile-down speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

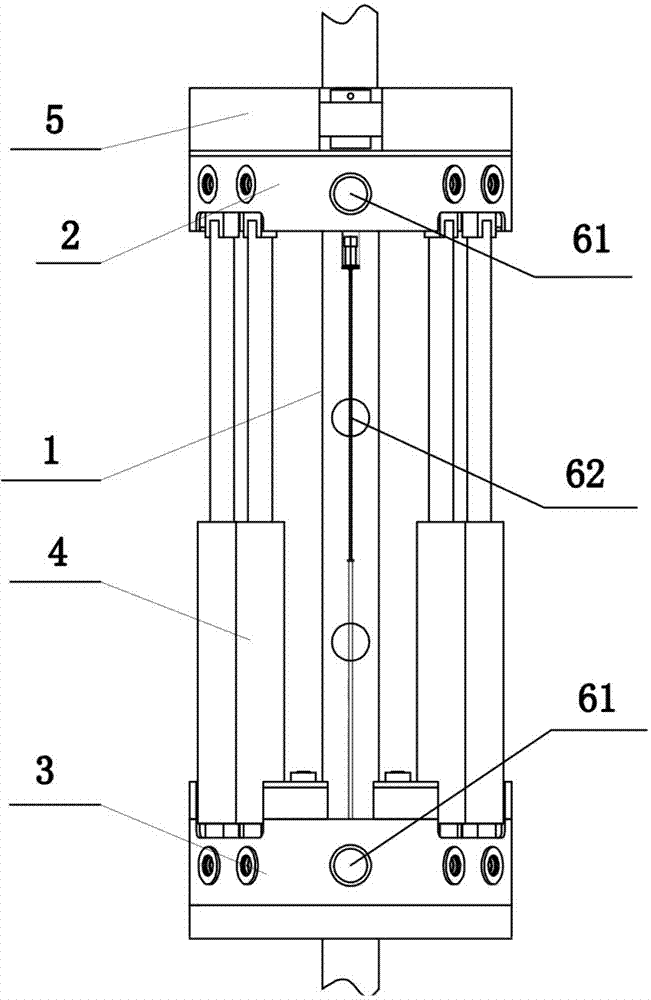

[0012] The technical solutions claimed in the present invention will be further described in detail in conjunction with the accompanying drawings and specific embodiments.

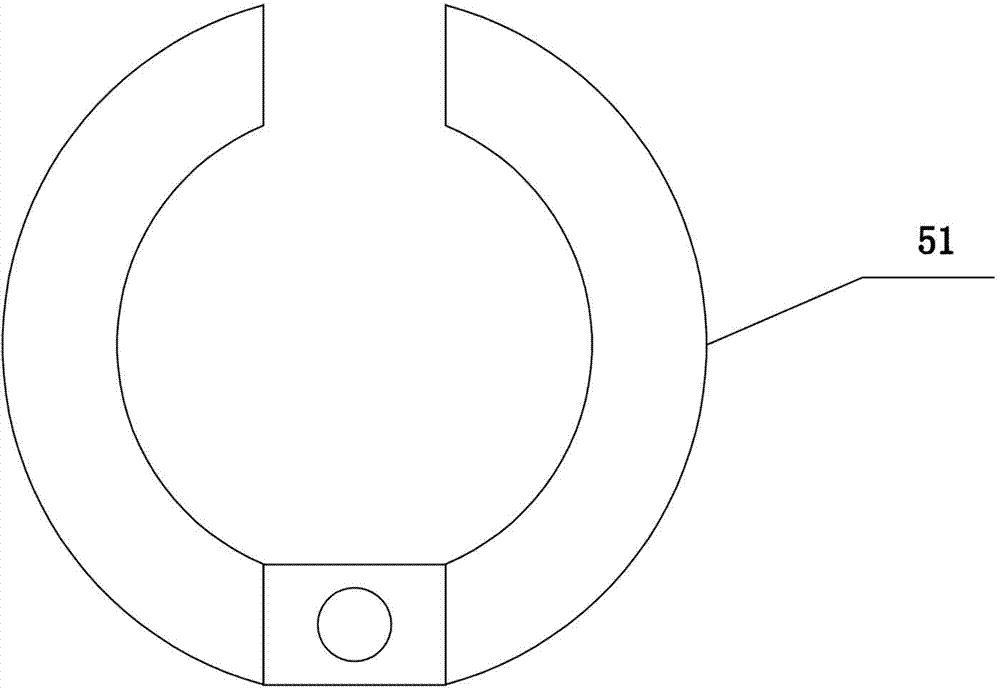

[0013] like figure 1 As shown, in this embodiment, the lifting device includes a positioning pile 1 , an upper ring beam 2 , a lower ring beam 3 , a lifting cylinder 4 and a clamper 5 . The positioning pile 1 runs through the upper ring beam 2 and the lower ring beam 3 in the longitudinal direction and makes a sliding connection between the positioning pile 1 and the upper ring beam 2 and the lower ring beam 3 . The lifting cylinder 4 is longitudinally connected between the upper ring beam 2 and the lower ring beam 3, and the driving of the lifting cylinder 4 makes the upper ring beam 2 and the lower ring beam 3 move relative to each other along the positioning pile 1 between the two ring beams, wherein The lower ring beam 3 is fixedly connected with the hull, and the upper ring beam 2 can move up and dow...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com