Clutch control valve

A clutch control valve and valve core technology, applied in the mechanical field, can solve the problems of flow regulation control, slow response speed of the valve core, etc., and achieve the effects of stable control, fast response speed and fast oil discharge speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

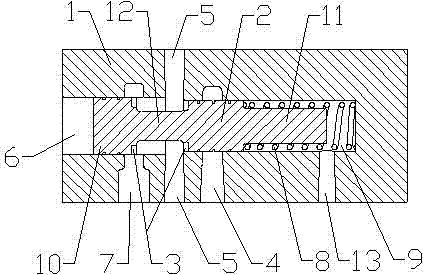

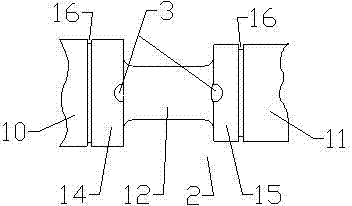

[0024] Examples such as figure 1 and figure 2 As shown, a clutch control valve includes a valve body 1, a valve cavity 9 is provided in the valve body 1, a valve core 2 is provided in the valve cavity 9, a spring 8 is provided between the tail 11 of the valve core 2 and the valve cavity 9 .

[0025] The spool 2 includes a head 10 and a tail 11, the outer diameter of the head 10 is greater than the outer diameter of the tail 11, a neck 12 is provided between the head 10 and the tail 11, the head 10 has a valve body 1 The first mating surface 14 matched with the inner wall, the tail part 11 has a second mating surface 15 mated with the inner wall of the valve body 1, the junction of the first mating surface 14 and the neck 12 is provided with a valve groove 3, the second mating surface 15 and the neck The joint of the part 12 is also provided with a valve slot 3, and the first mating surface 14 is provided with 2 or 4 valve slots 3, and the second mating surface 15 is also pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com