PTA transport vehicle for unloading of screw conveyor

A technology of screw conveyor and transport vehicle, applied in the direction of goods transport vehicles, motor vehicles, transport objects, etc., can solve the problems of slow unloading speed, PTA burning, high center of gravity, improve unloading speed and quality, prevent burning and The effect of explosion and fast unloading speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

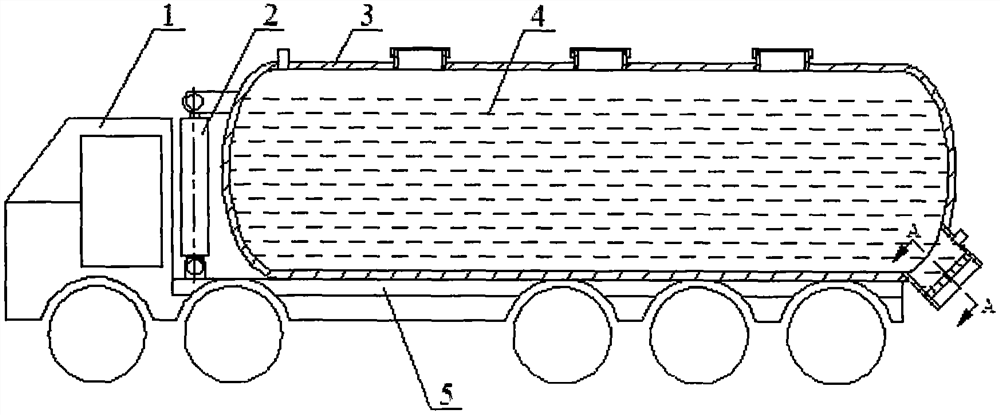

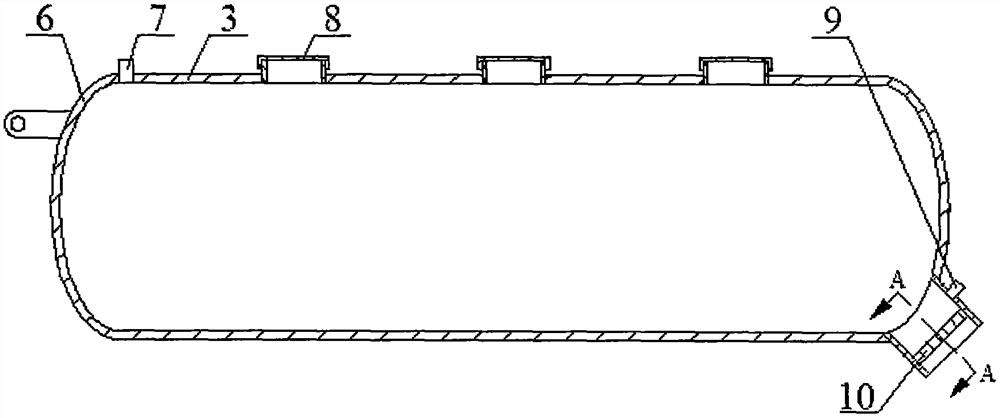

[0035]Example 1: a PTA transport vehicle with a spiral conveyor discharge monitoring system with a strain piece sensor unloading monitoring system.

[0036]On the basis of the current PTA transport vehicle, the screw conveyor and the strain sheet sensor discharge monitoring system are increased, which is a PTA transport vehicle with a spiral conveyor discharge monitoring system with a strain piece sensor unloading monitoring system.

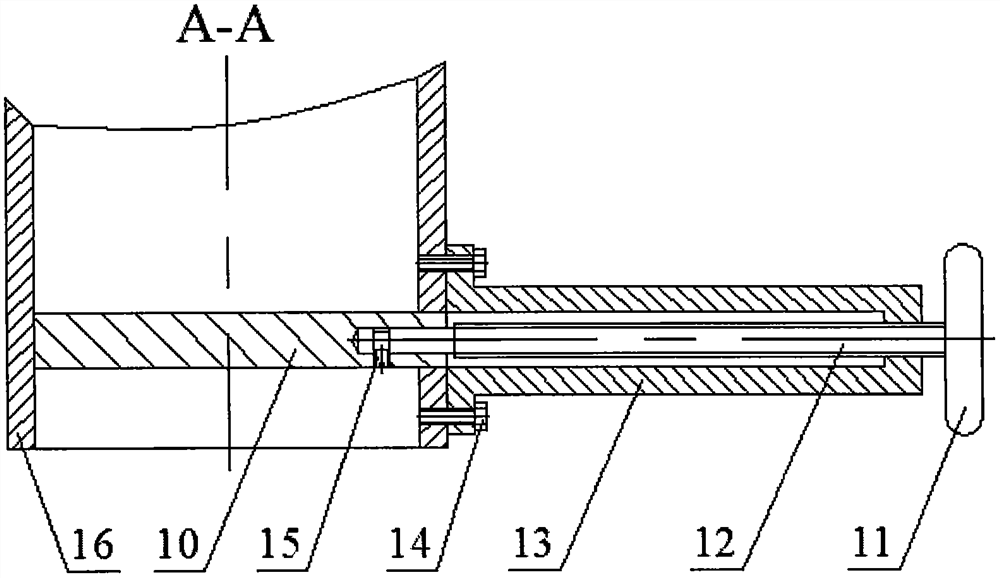

[0037]The screw conveyor includes a spiral blade 19, an elastic baffle 20, an input shaft 21, and a motor 22; the spiral blade 19 is at the bottom of the can body 6, and one end of the spiral blade 19 is at the discharge tube 16 and is close to the shield door 10, a spiral blade. 19 The other end is coupled to the input shaft 21, and the input shaft 21 is coupled to the output shaft of the motor 22, and the motor 22 is fixed to the can body 6; the elastic baffle 20 surrounds both sides of the spiral blade 19, elastic blocking The lower end of the plate 20 is...

Embodiment 2

[0045]Example 2: PTA transport vehicle with a helical conveyor discharge monitoring system with a hydraulic sensor discharge monitoring system.

[0046]With the oil pressure sensor discharge monitoring system replace the strain chip sensor discharge monitoring system in Example 1, it is a PTA transport vehicle with a helical conveyor discharge monitoring system with a hydraulic sensor unloading monitoring system, and the structure and working principle are only unloaded. The structure and working principle of the system are different.

[0047]The hydraulic sensor discharge monitoring system includes a hydraulic sensor 18, a monitor 26, and a wire 27, and the hydraulic pressure sensor 18 is mounted on the hydraulic cylinder 2 or the oil pressure sensor 18 passes through the electric wire 27 and the monitor 26. connection.

[0048]The principle and method of monitoring the discharge monitoring system: one end of the can body 6 is lifted by the hydraulic cylinder 2, and the weight of the can bo...

Embodiment 3

[0050]Example 3: Spiral conveyor discharge of unloading monitoring system Unloading PTA transport vehicle.

[0051]Remove the strain chip sensor discharge monitoring system in Example 1, which is a PTA transport vehicle of a spiral conveyor unloading of a non-excimer monitoring system.

[0052]PTA transport vehicle with a spiral conveyor discharge monitoring system with a strain piece sensor unloading monitoring system, a spiral conveyor unloading of a hydraulic sensor unloading monitoring system, a spiral conveyor discharge of a non-excimer monitoring system The PTA transport vehicle is a spiral conveyor unloading PTA transport vehicle, but also simultaneously uses a strain piece sensor unloading monitoring system and an oil pressure sensor discharge monitoring system to improve the accuracy of monitoring discharge.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com