Hazardous waste incineration fly ash self-cleaning device

A self-cleaning, fly ash technology, applied in the direction of incinerators, combustion methods, lighting and heating equipment, etc., can solve the problems of not considering the combustion of hazardous waste, not taking into account, and reducing the incineration space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

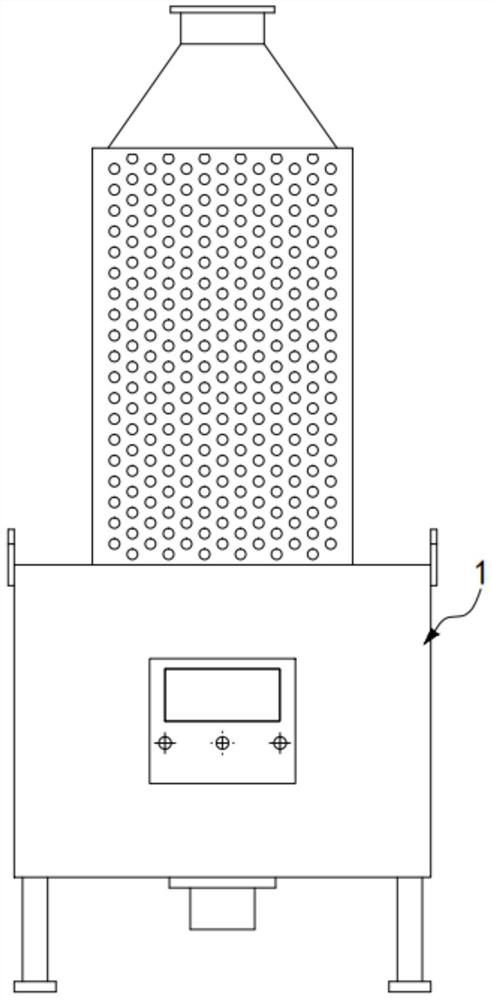

[0057] like Figure 1 to Figure 10 As shown, a hazardous waste incineration fly ash self-cleaning device includes pretreatment and feeding equipment, incineration equipment, waste heat boiler equipment, quenching device and deacidification and dust removal equipment. The incineration equipment includes a primary combustion chamber and a secondary combustion chamber. chamber, the primary combustion chamber includes:

[0058] Combustion chamber body 1, the combustion chamber body 1 is provided with a combustion space, and the combustion chamber body 1 is connected with the feeding device;

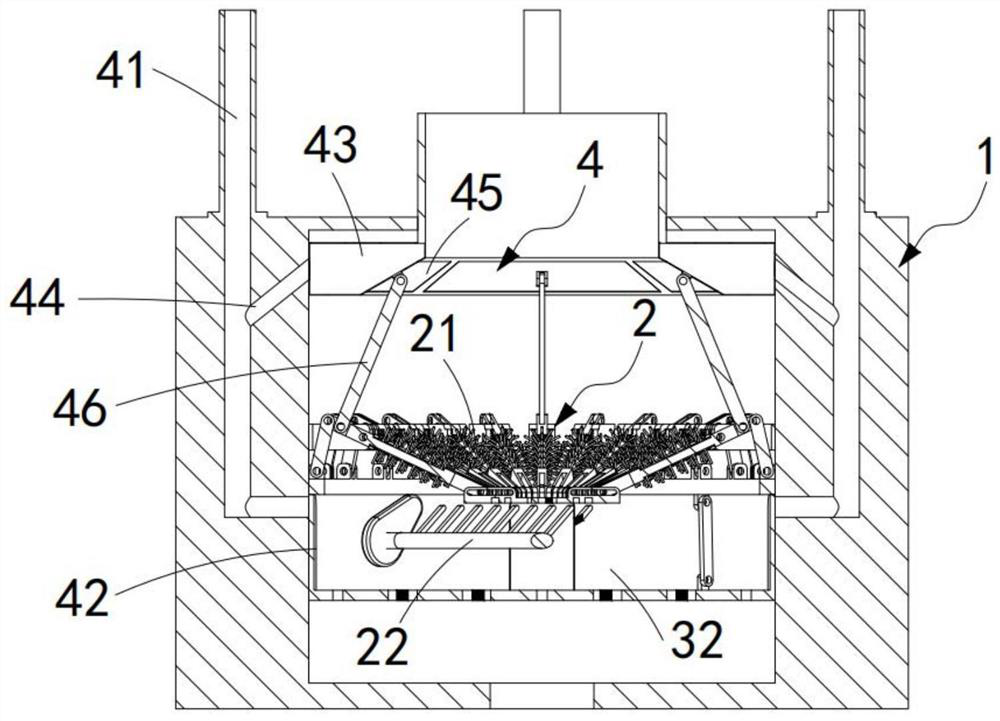

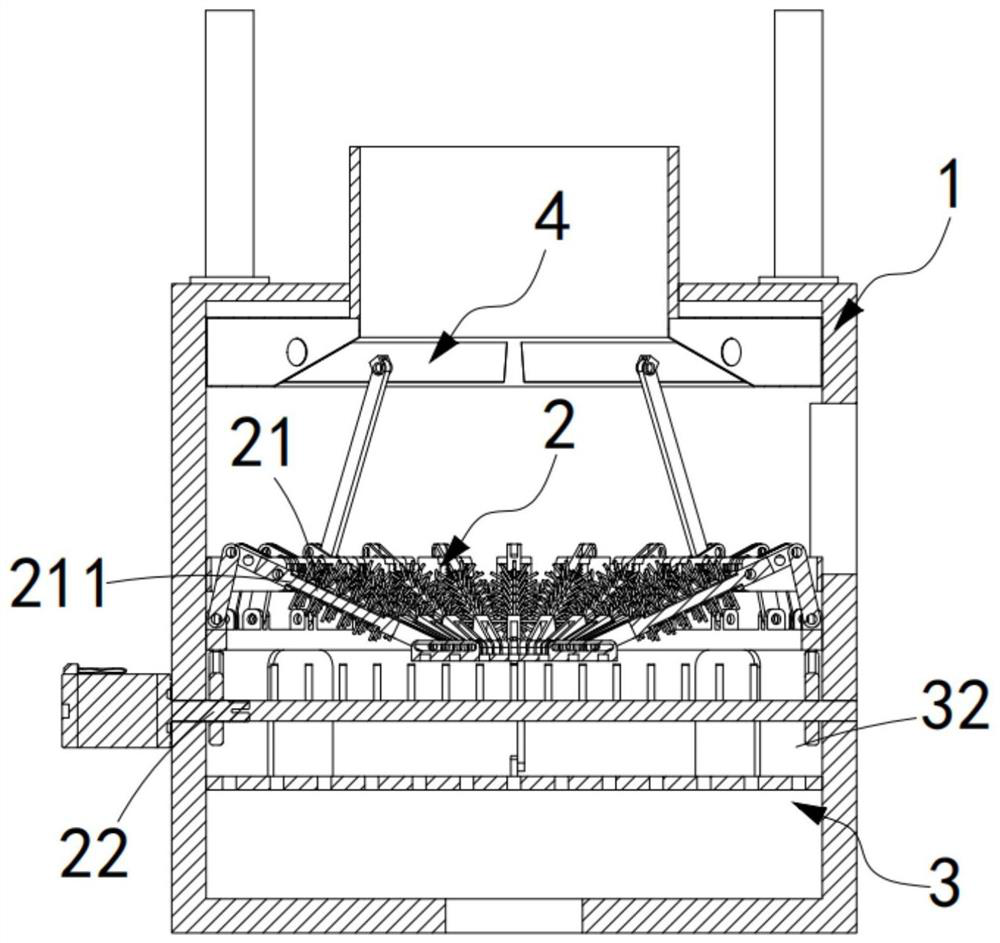

[0059] A dismantling mechanism 2, the dismantling mechanism 2 is installed in the lower part of the combustion space in the combustion chamber body 1, the dismantling mechanism 2 is used to disperse the hazardous wastes input by the rotary kiln, and the dismantling mechanism 2 includes dismantling A material assembly 21 and a drive assembly 22. The material removal assembly 21 is installed o...

Embodiment approach

[0084] As a preferred embodiment, the fly ash self-cleaning mechanism 4 includes:

[0085] A combustion-supporting passage 41, the combustion-supporting passage 41 is arranged in the side wall of the combustion chamber body 1, a mixture of a combustion-supporting agent and air circulates in the combustion-supporting passage 41, and the outlet of the combustion-supporting passage 41 is located in the auxiliary combustion zone 32 ;as well as

[0086] Movable sealing plate 42, described movable sealing plate 42 is installed on the described fire grate 3, this movable sealing plate 42 switches the outlet of described combustion-supporting channel 41 with the lifting of described fire grate 3;

[0087] The ash collection bin 43, the ash collection bin 43 is arranged directly above the dismantling mechanism 2, the ash collection bin 43 communicates with the combustion-supporting channel 41 through a communication branch pipe 44, and the communication branch pipe 44 is arranged obliq...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com