Automatic charging and discharging and transmitting device for handstand type numerical controlled lathe

An automatic loading and unloading, CNC lathe technology, applied in the field of CNC lathes, can solve the problems of many machining surfaces, the influence of weight on the clamping accuracy, and the incompetence of horizontal CNC lathes, so as to reduce labor intensity and realize automatic factory production. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] Figure 1-Figure 3 It is a schematic structural diagram of a specific embodiment of the present invention and its various parts. The embodiments of the present invention will be described below in conjunction with the accompanying drawings.

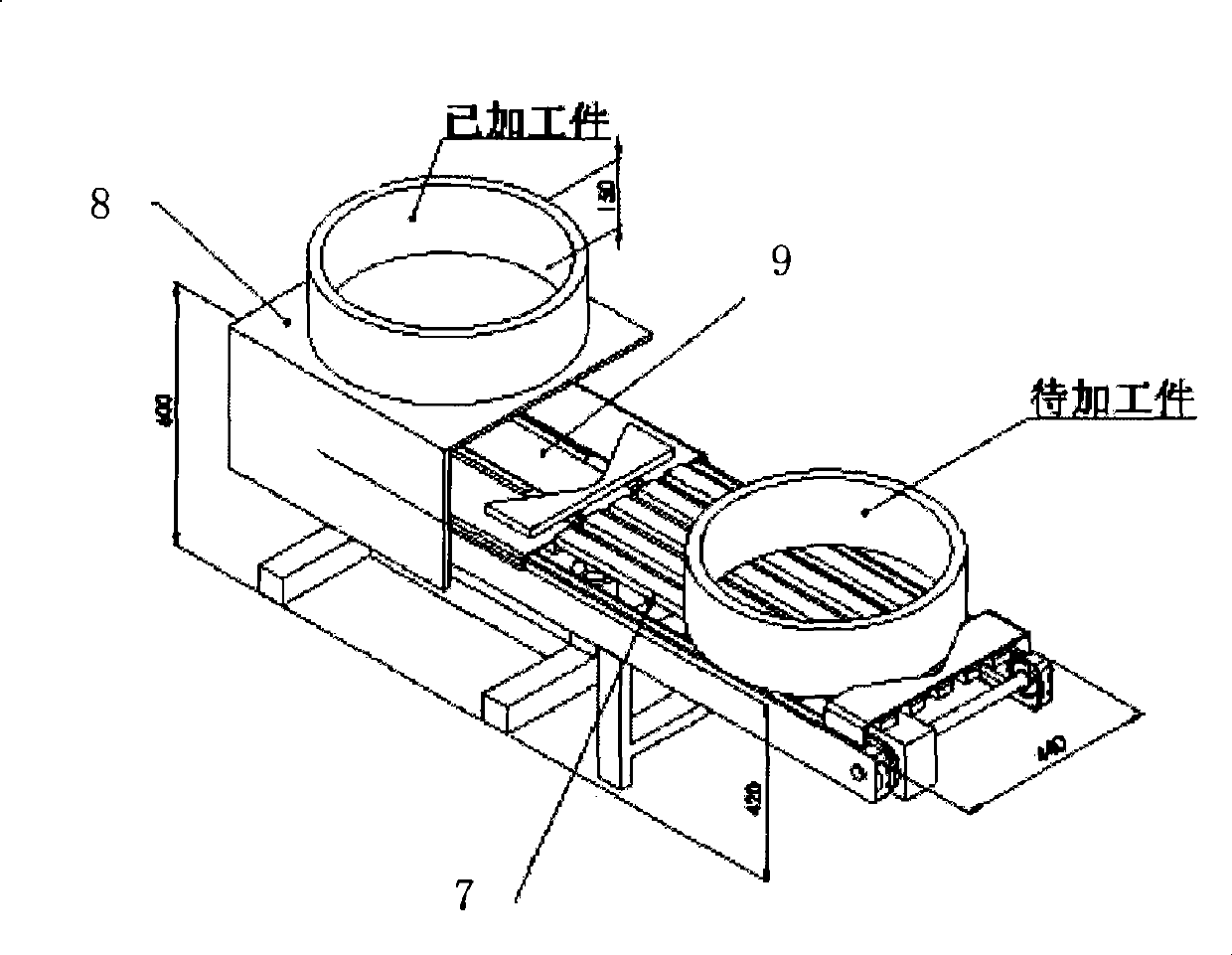

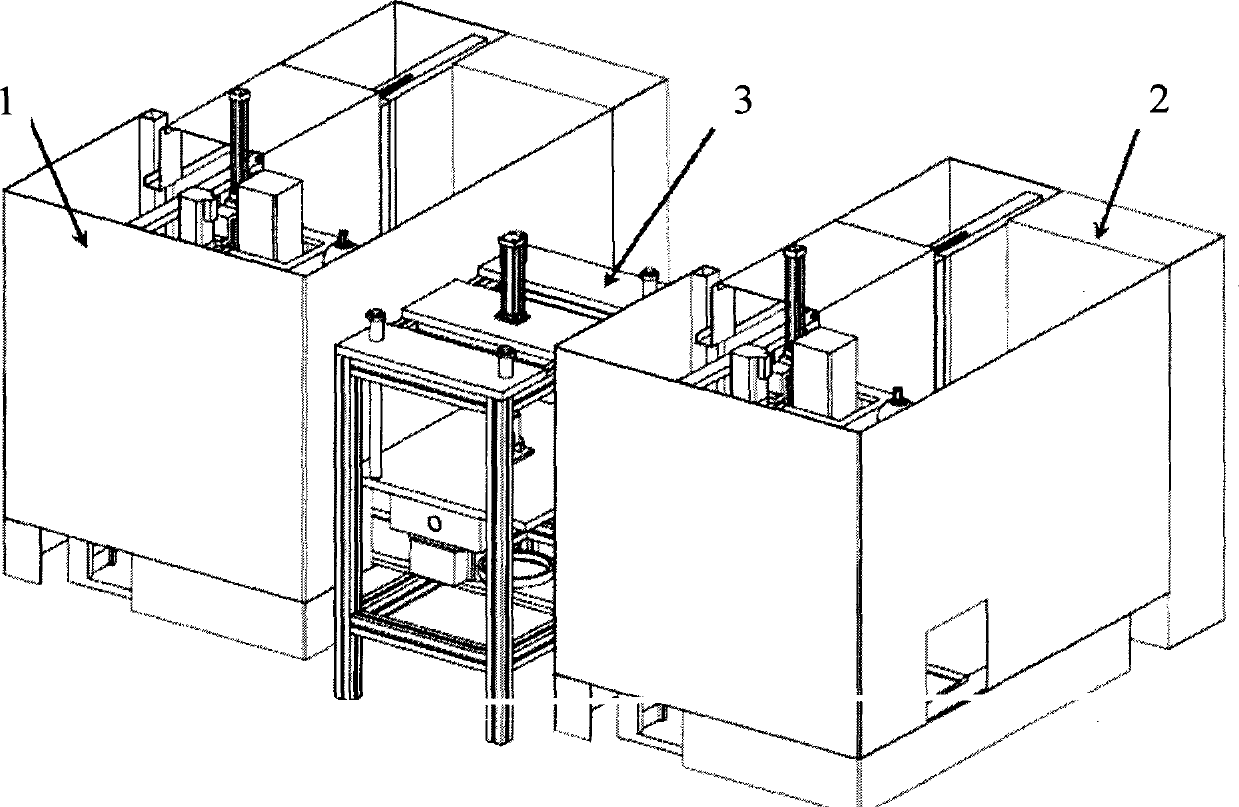

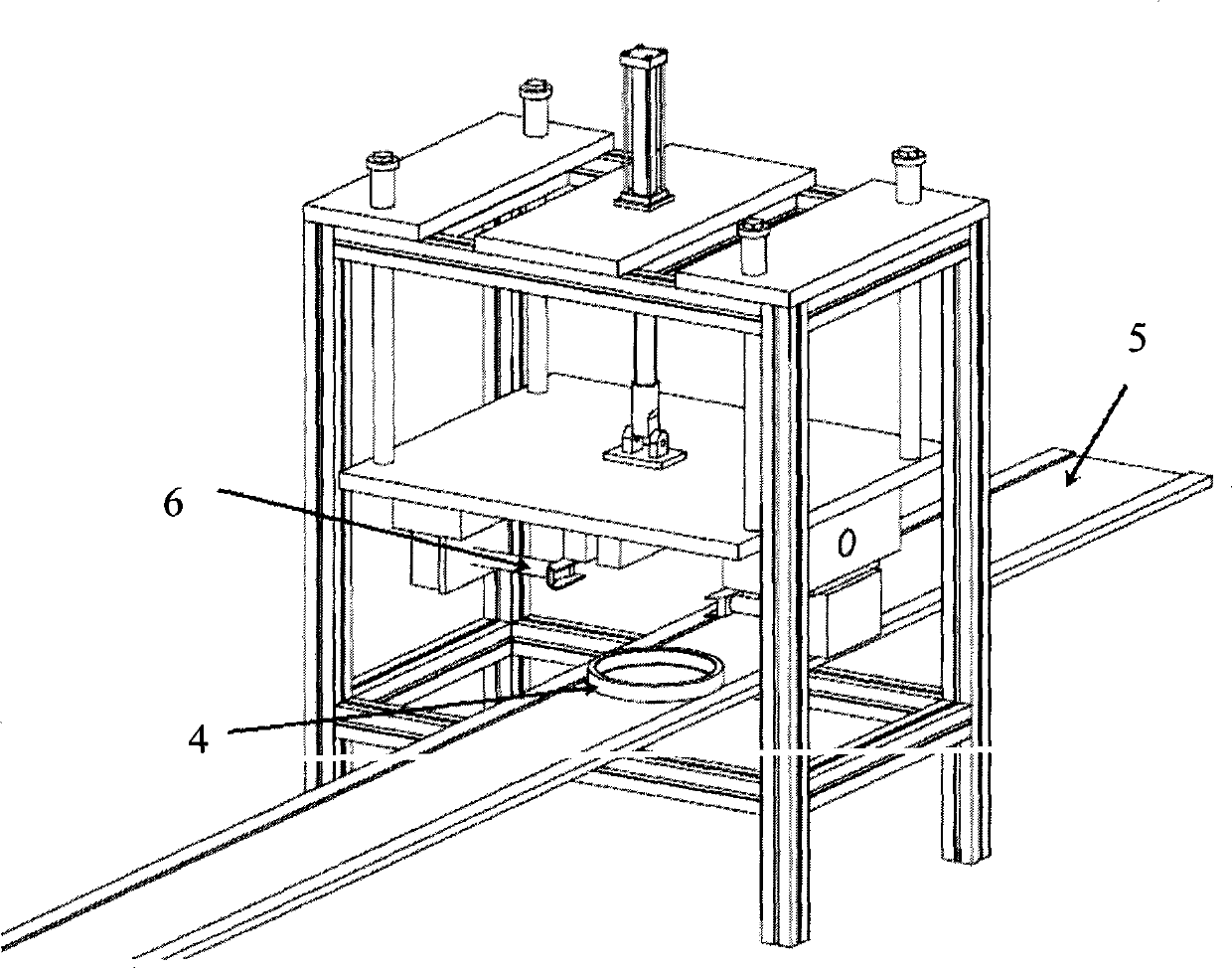

[0016] Such as figure 1 As shown, a kind of automatic loading and unloading and conveying device that is used for inverted numerical control lathe of the present invention comprises loading and unloading platform, conveying guide rail 5 and workpiece turnover mechanism 3, and loading and unloading platform is arranged on each inverted numerical control lathe 1,2 On one side of the bed, there is a conveying hole behind the bed. The conveying guide rail 5 is arranged from the conveying hole to the loading and unloading platform and the inverted CNC lathes 1 and 2 are connected to each other. The workpiece turning mechanism 3 is arranged on each inverted CNC lathe. On the conveying rail 5 between the lathes 1 and 2. Such as figur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com