Double-vortex combustion chamber

A combustion chamber and flame tube technology, applied in the field of double-vortex combustion chambers, can solve the problems of insufficiently uniform distribution of fuel concentration field, insufficient residence time, unfavorable formation of vortex, etc., so as to improve the distribution of fuel concentration field and omit the cooling air flow path , the effect of reducing weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The present invention will be further described in detail below in conjunction with the accompanying drawings.

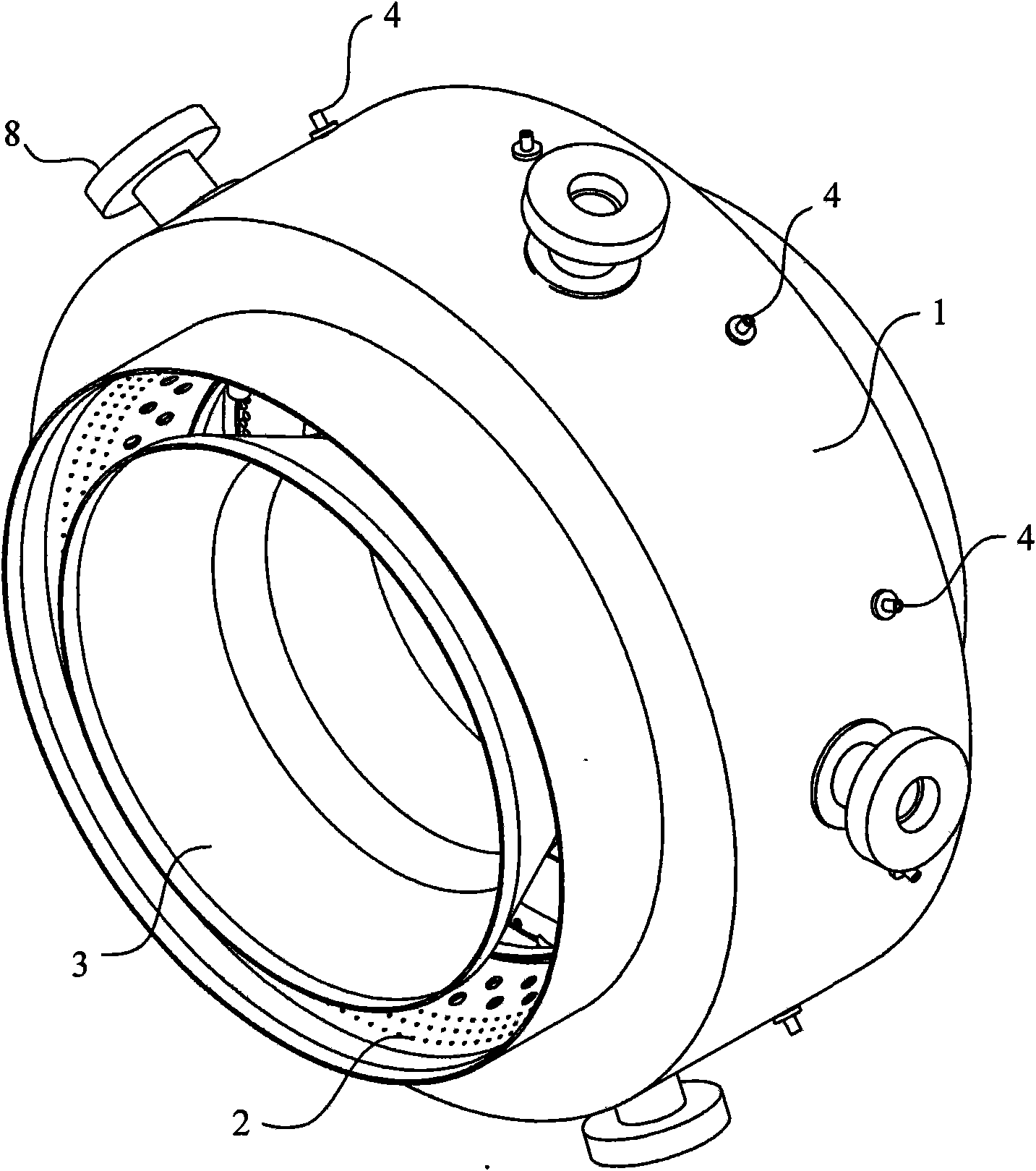

[0041] The present invention is a twin-scroll combustor, such as figure 1 As shown, it includes a shell 1, an outer flame tube 2 and an inner flame tube 3. Five ignition seats 8 and ten fuel injection pipes 4 are evenly arranged in the circumferential direction of the housing 1 .

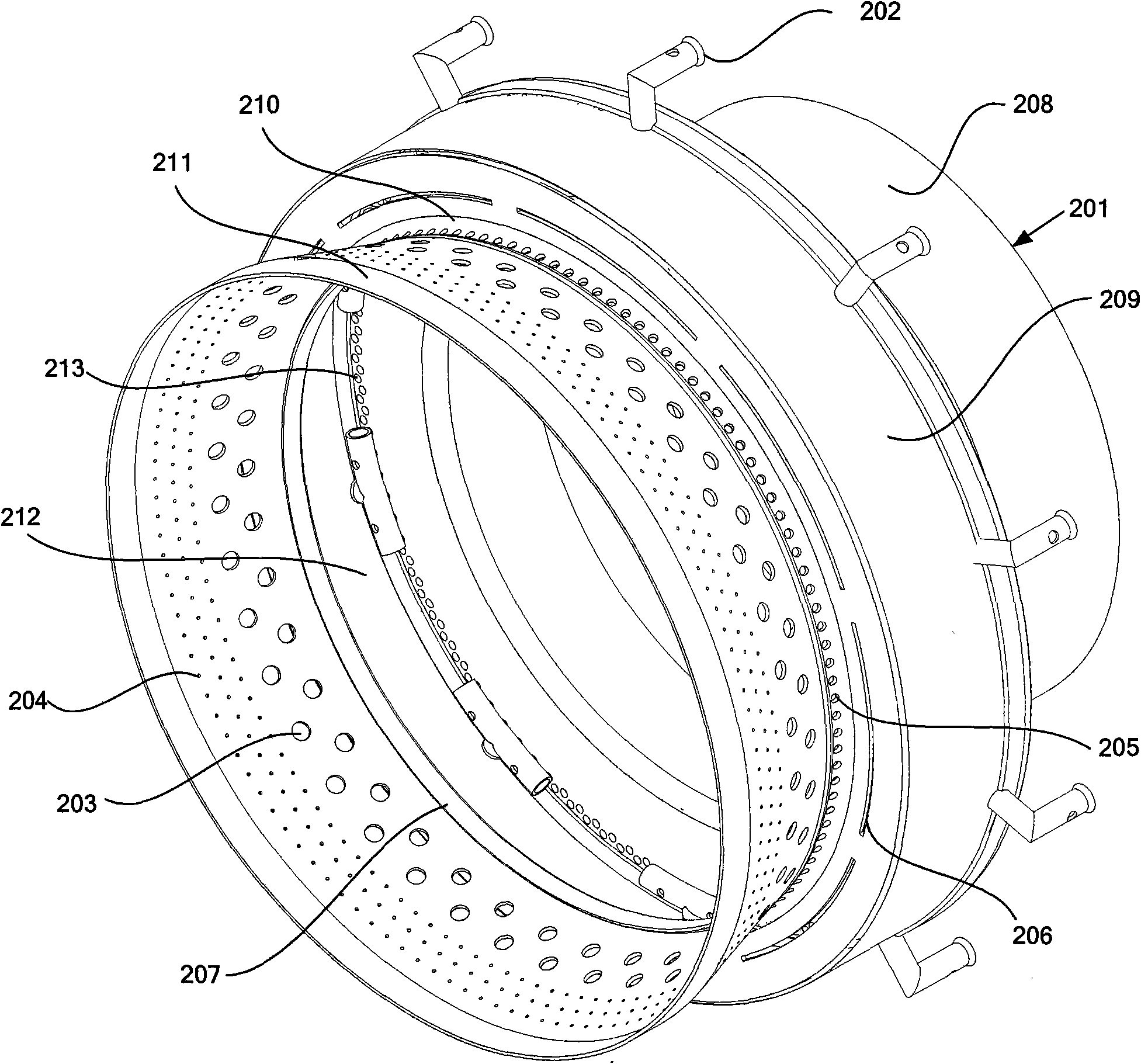

[0042] like figure 2 As shown, the outer layer flame tube base 201 is divided into four sections, namely the first section 208 of the outer layer flame tube base body, the second section 209 of the outer layer flame tube base body, the third section 210 of the outer layer flame tube base body, and the outer layer flame tube base body. The fourth section 211 of the flame cylinder substrate.

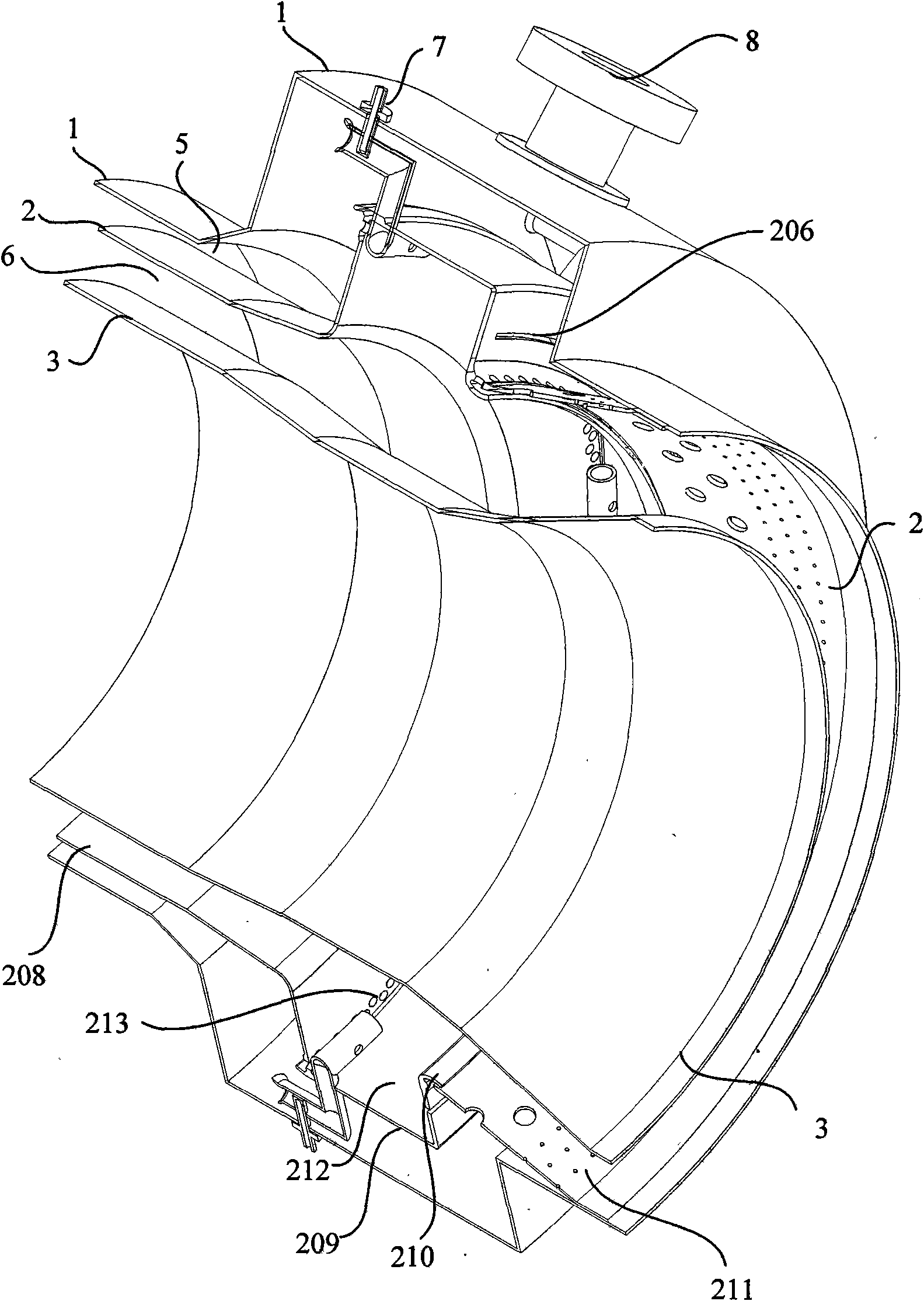

[0043] like figure 2 and image 3 As shown, the outer wall of the inner flame tube 3 and the inner wall of the outer flame tube 2 form a combustion channel 6 for combustion of the oil-ga...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com