Water purifying equipment with directional selective reverse osmosis filtering structure

A technology of water purification equipment and filtration structure, applied in water/sewage treatment equipment, osmosis/dialysis water/sewage treatment, water/sewage treatment, etc. The concentration ratio of wastewater to purified water cannot be further improved, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Next, the technical solutions in the embodiments of the present invention will be apparent from the embodiment of the present invention, and it is clearly described, and it is understood that the described embodiments are merely embodiments of the present invention, not all of the embodiments. Based on the embodiments of the present invention, there are all other embodiments obtained without making creative labor without making creative labor premises.

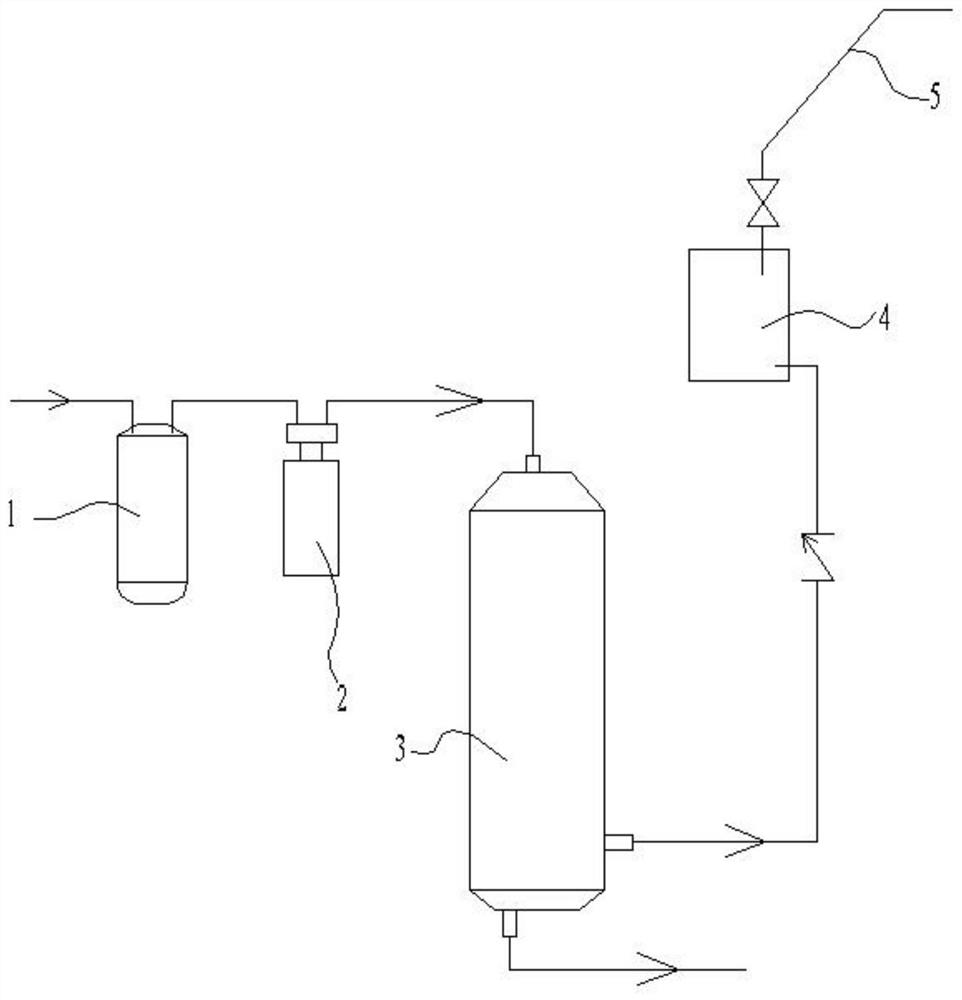

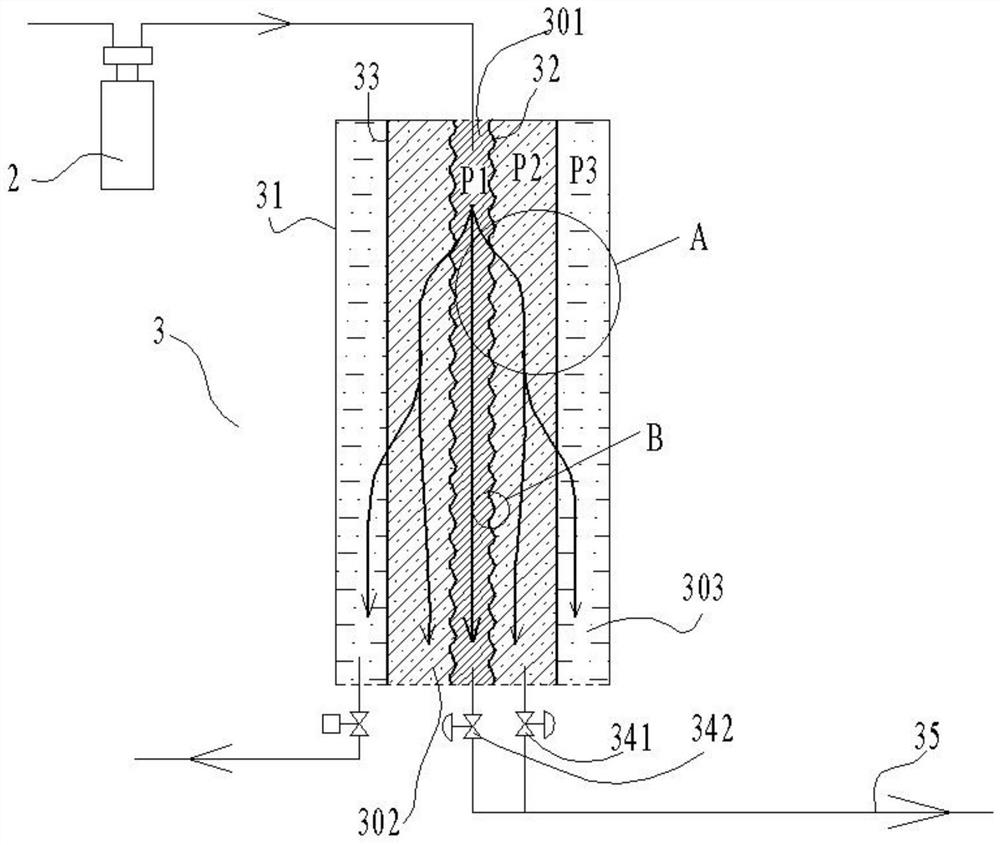

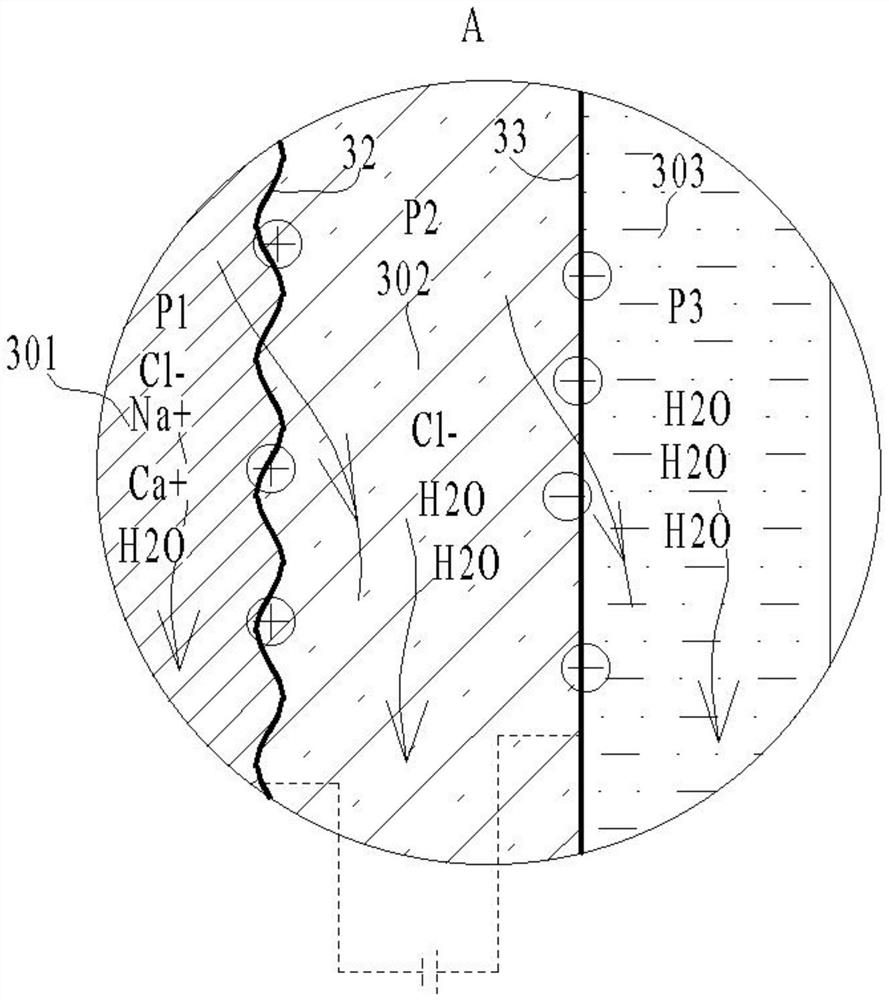

[0023] See Figure 1-5 The present invention provides a technical solution:

[0024]A water purification apparatus with a directional selective reverse osmosis filter comprising an inlet filter element 1, a pressurizing pump 2, a reverse osmosis filter 3, an inlet filter element 1, a booster pump 2, and the reverse osmosis filter 3 sequentially passed through a water pipe. Let together, the reverse osmosis filter 3 includes a housing 31, a first semipermeable film 32, a second semiperm film 33, and a bleed opening 35, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com