Spraying nozzle device for electrostatic spinning

An electrostatic spinning and nozzle technology, which is applied in the directions of spinneret assembly, textile and papermaking, filament/line forming, etc. Difficulty reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

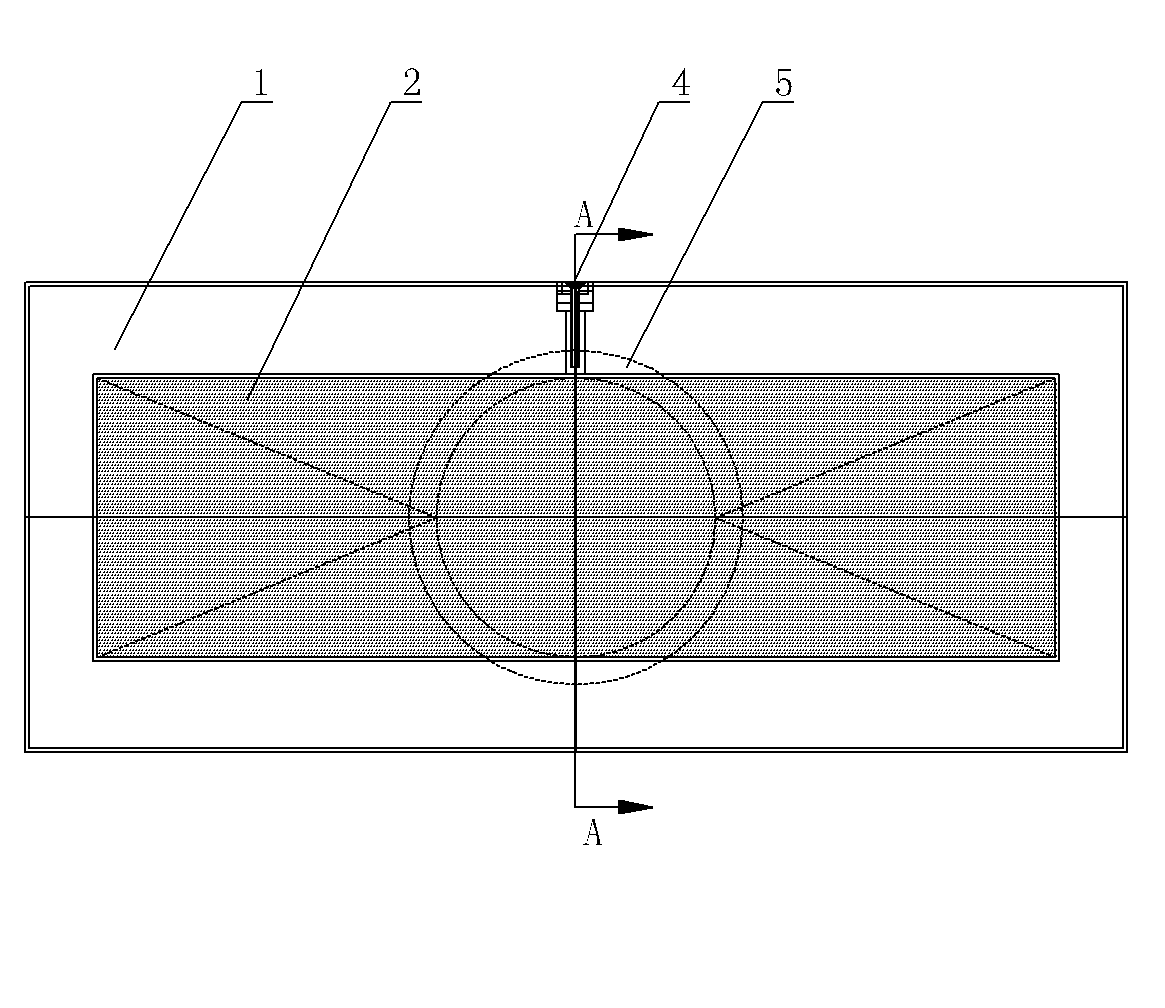

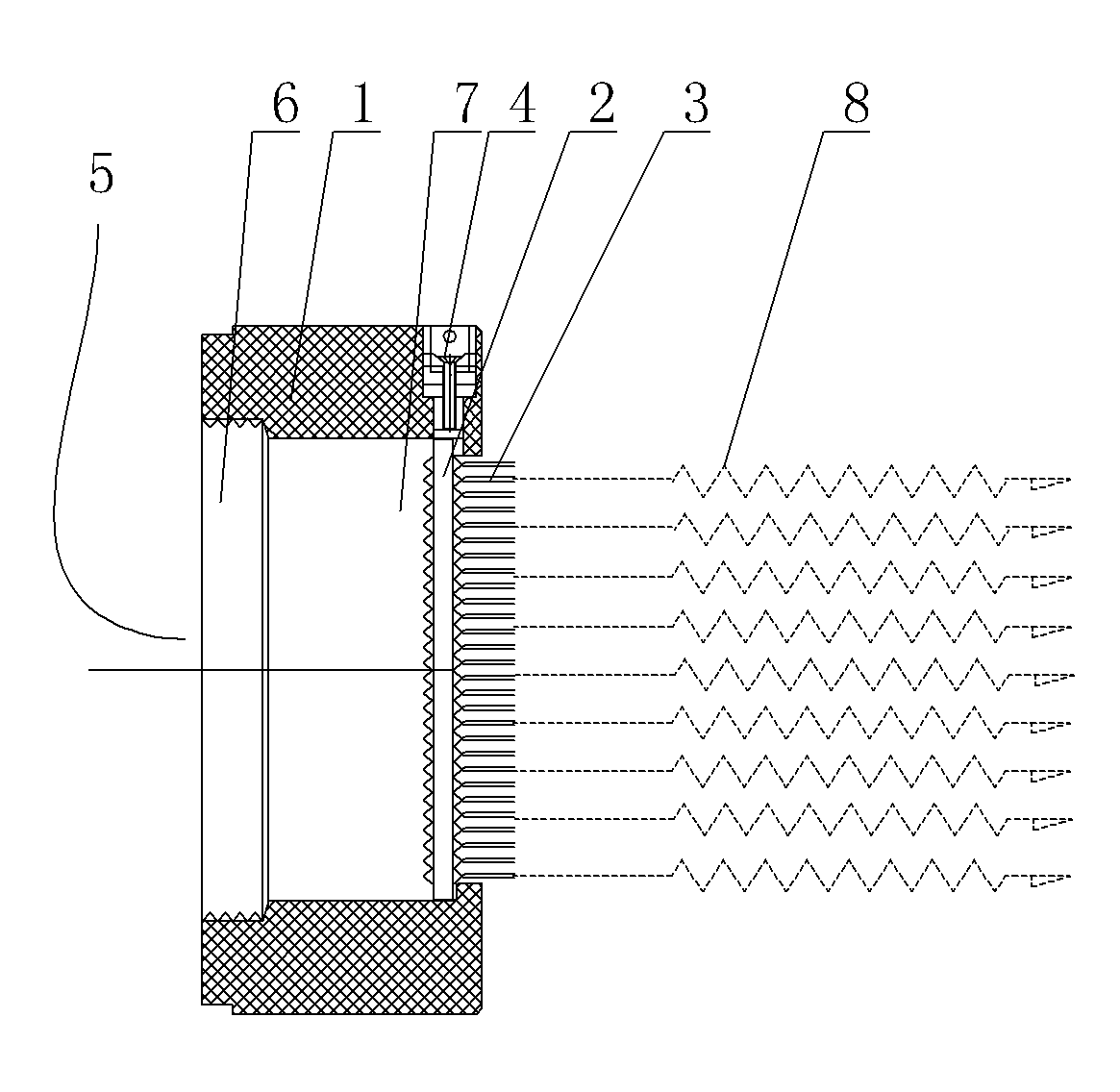

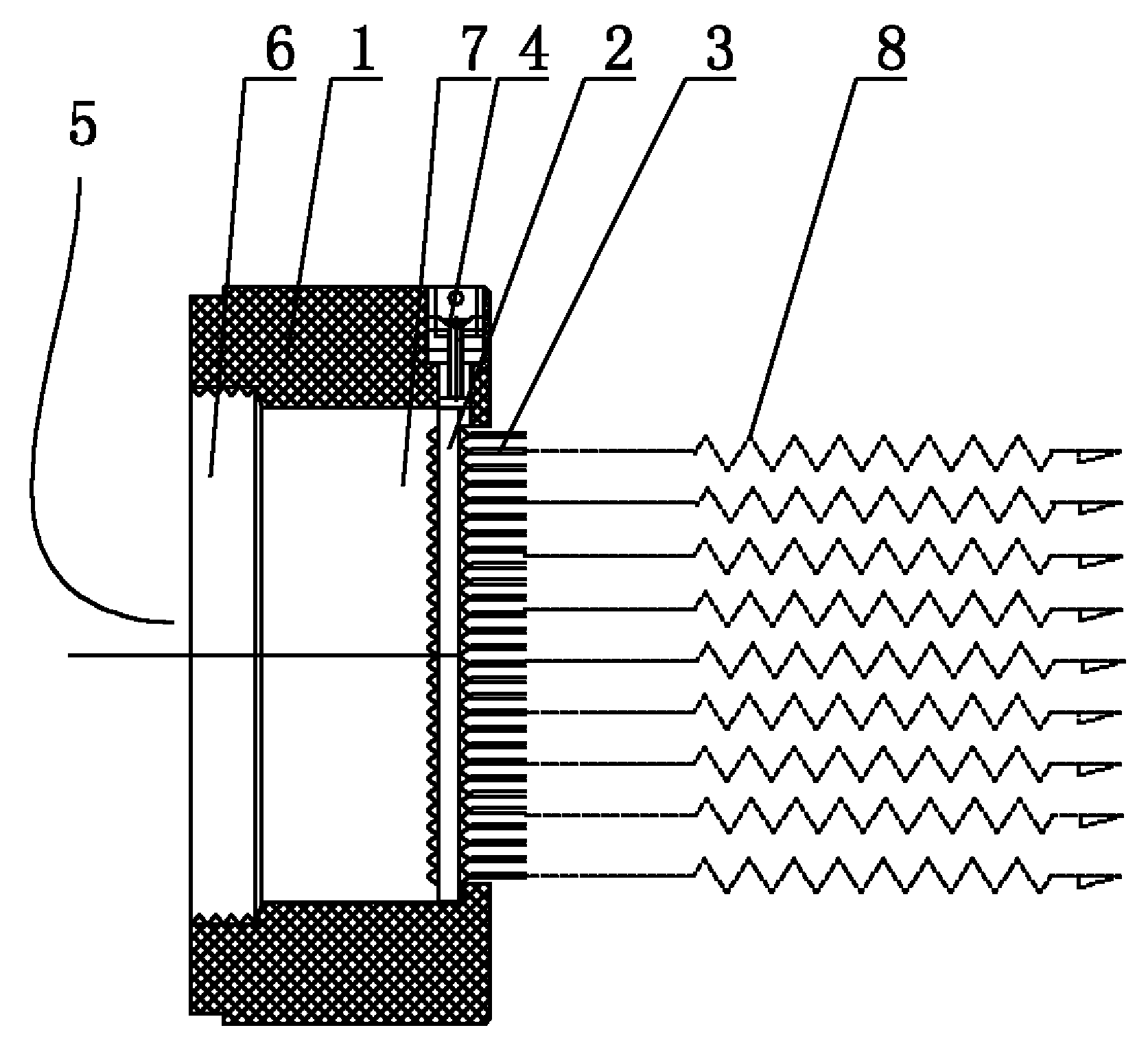

[0014] Embodiment 1 of the nozzle device for electrospinning of the present invention, such as figure 1 and figure 2 As shown, it is composed of an insulating cover 1, a shunt net 2, a guide wire 3 and a terminal 4. The inside of the insulating cover 1 has a spinning solution flow channel 5 for the circulation of the spinning solution. The liquid outlet 7 where the silk liquid flows out, wherein the liquid outlet 7 is a flared opening relative to the spinning liquid flow channel; the shunt net 2 is covered at the liquid outlet 7, and the guide wires 3 are densely arranged and fixedly connected to the shunt net 2 On the side away from the liquid inlet 6, the mesh surface of the side of the shunt net 2 with the guide wires is a plane, and each guide wire is perpendicular to the mesh surface; the shunt net 2 and the guide wire 3 are made of conductive materials Made; the distribution net 2 is used to break up the spinning liquid flow flowing out from the spinning liquid flow c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com