Heat radiation assembly and its flow direction control structure

A technology for heat dissipation components and flow direction control, which is applied in the field of heat dissipation components and their flow direction control structures, and can solve the problems that heat energy cannot be dissipated well, the area of the air outlet is reduced, and heat cannot be effectively dissipated.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

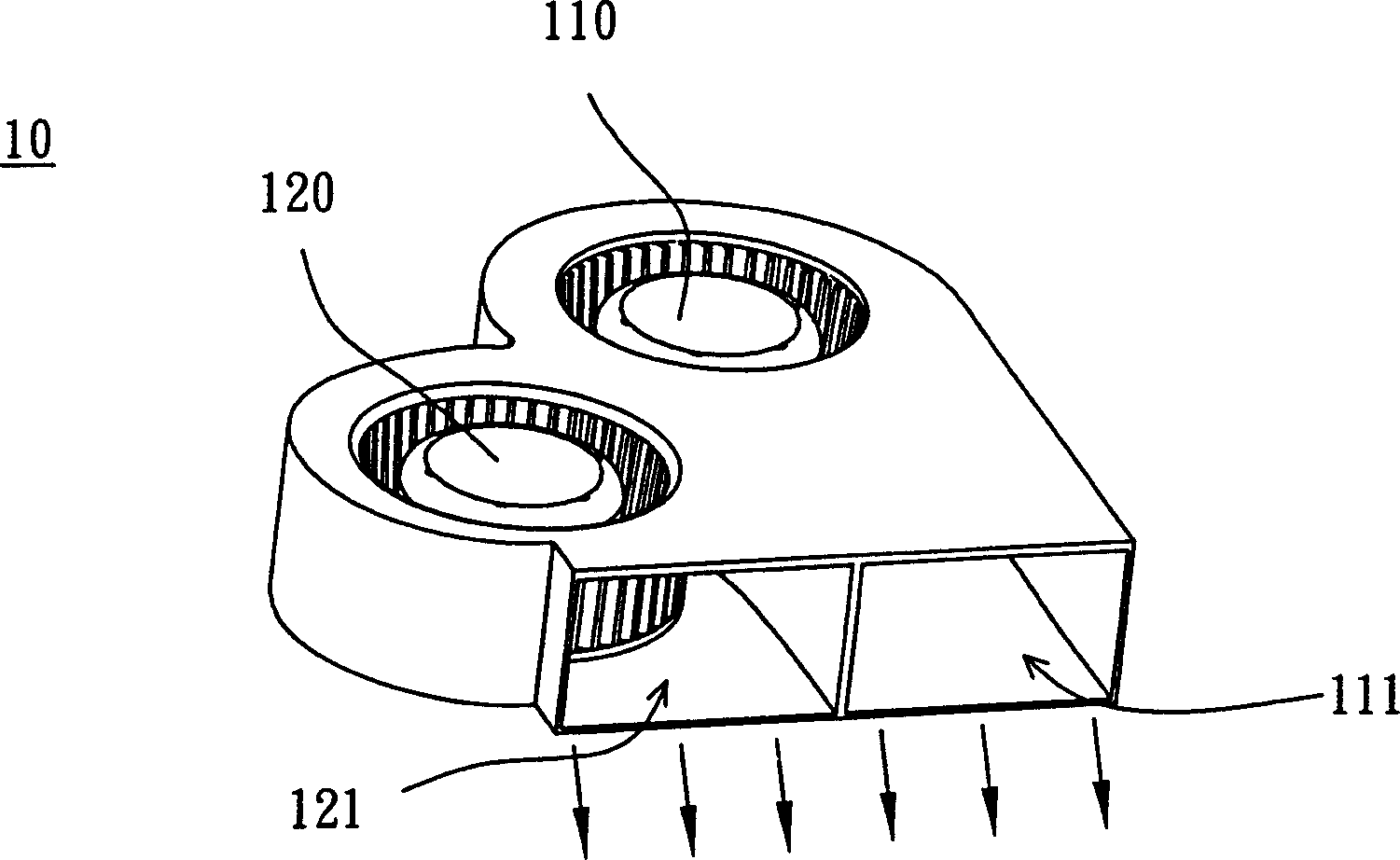

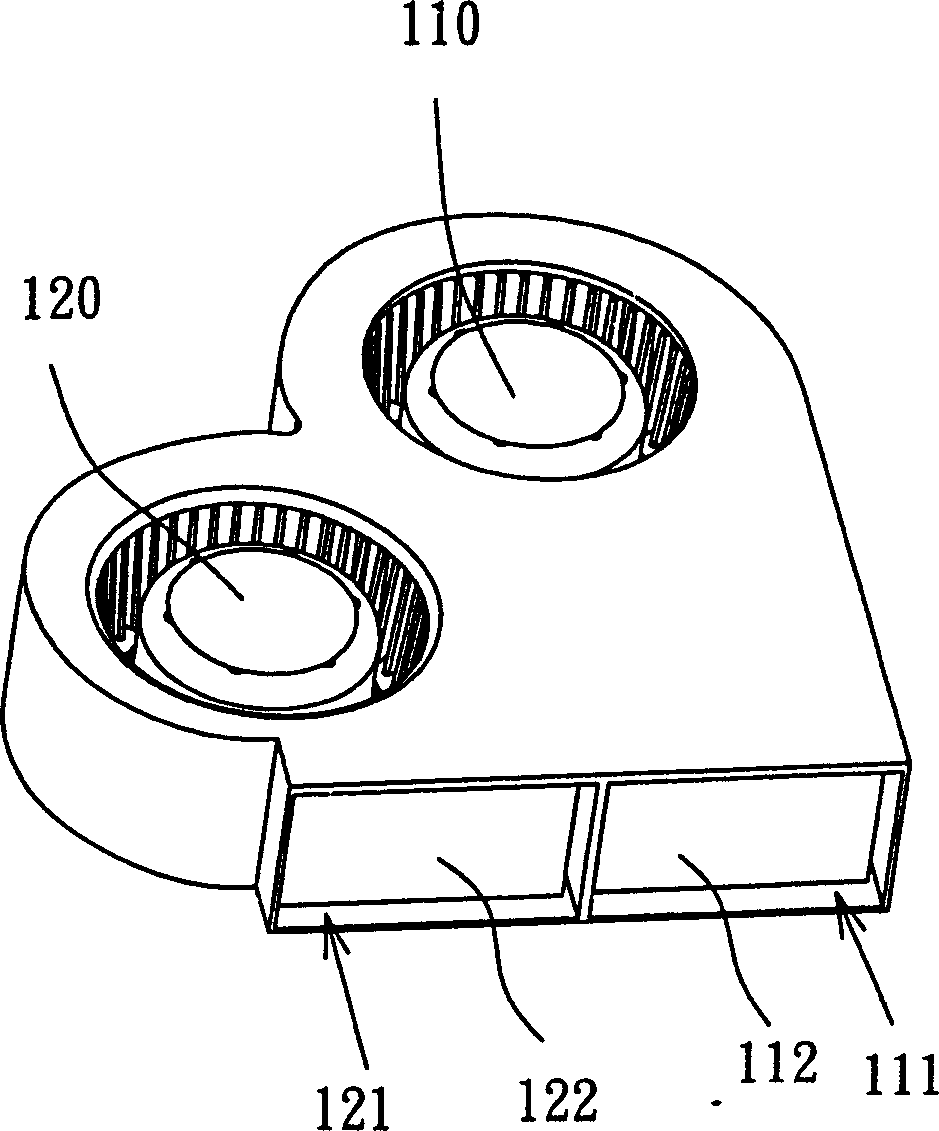

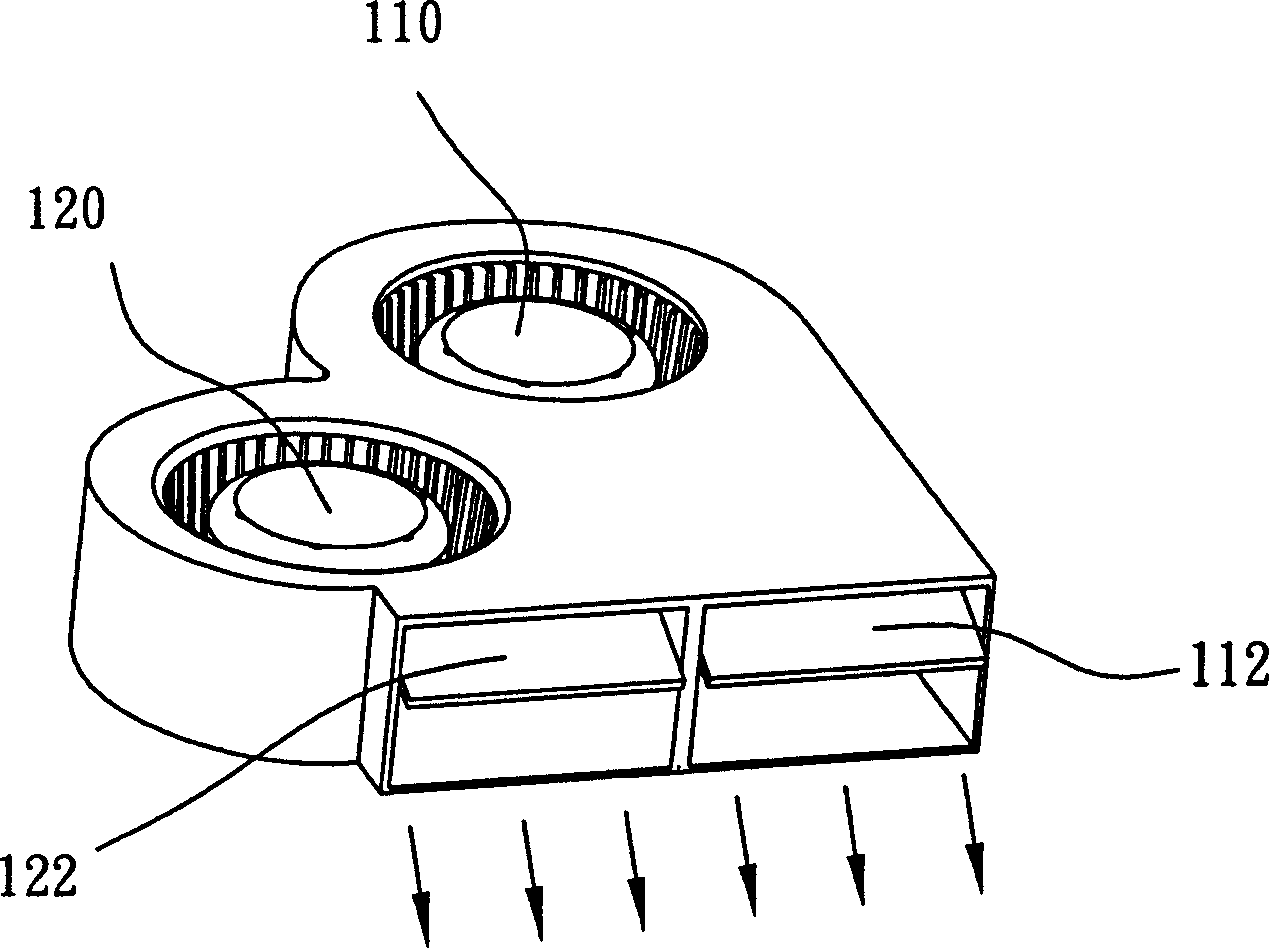

[0032] Please refer to Figure 2A and Figure 2B , which is a schematic diagram of the flow direction control structure according to the first embodiment of the present invention. For the sake of illustration, as Figure 2A As shown, the upper cover of the heat sink is removed to better understand the flow control structure. The flow direction control structure of this embodiment is used in a heat dissipation device 210, such as a blower fan (blower). The flow direction control structure includes several movable parts 23, which are arranged on the air outlet 211 of the heat dissipation device 210. Each movable part 23 has a fixed first end 231 and a corresponding movable second end 232 for use in To jointly guide the airflow direction.

[0033] The flow direction control structure is formed in a modular form, and is installed in any one or more appropriate positions of the heat sink 210 in a detachable manner. Each movable part 23 is rotatably arranged at the air outlet, ...

no. 2 example

[0037] Please refer to Figure 3A and Figure 3B , Figure 3A is a schematic diagram of a heat dissipation assembly according to a second embodiment of the present invention, and Figure 3B yes Figure 3A Top view of the thermal assembly. The heat dissipation assembly 30 of this embodiment is, for example, a parallel fan, which at least includes a first heat dissipation device 310 , a second heat dissipation device 320 , and a flow direction control structure. The first heat dissipation device 310 and the second heat dissipation device 320 are arranged symmetrically, and an imaginary line passing through the connection point between the first heat dissipation device 310 and the second heat dissipation device 320 is taken as the criterion. The flow direction control structure includes several movable parts 33, which are arranged between the first heat sink 310 and the second heat sink 320, and an imaginary line passing through the connecting point between the first heat sin...

no. 3 example

[0045] Please refer to Figure 4A and Figure 4B , Figure 4A is a schematic diagram of a heat dissipation assembly according to a third embodiment of the present invention, and Figure 4B yes Figure 4A Top view of the thermal assembly. Similar to the second embodiment, the heat dissipation assembly 40 of this embodiment is, for example, a parallel fan, which at least includes a first heat dissipation device 410 , a second heat dissipation device 420 , and a flow direction control structure. The first heat dissipation device 410 and the second heat dissipation device 420 are arranged symmetrically, and an imaginary line passing through the connection point between the first heat dissipation device 410 and the second heat dissipation device 420 is taken as the criterion. The flow direction control structure includes a plurality of movable parts 43, which are arranged between the first heat sink 410 and the second heat sink 420, and an imaginary line passing through the con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com