Gas turbine engine blade with inner meshed structure

An engine blade and internal structure technology, applied in the direction of engine components, machines/engines, blade support components, etc., can solve the problems of low processing yield, reduce design and processing costs, unable to manufacture complex internal structures, etc., to increase contact area, reduce design and processing costs, and improve the effect of overall stress uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

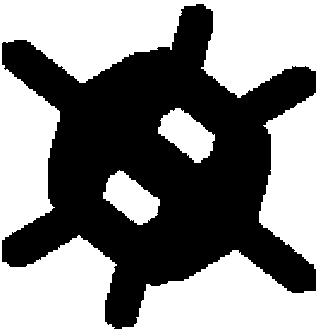

[0030] Fig. 3 is a schematic diagram of cross-grid filling inside the hollow airfoil without diverter partitions, including airfoil 1 (Fig. 3(a)) and grid structure 2 (Fig. 3(b)). Both the thickness of the airfoil 1 and the periodic size of the substructure of the grid are 2 mm. After filling the grid structure, the internal heat exchange area of the blade increases by ~130%. The simplified simulation calculation results show that under the same inlet cooling gas condition, the heat transfer capacity of the structure can be increased by 45%.

Embodiment 2

[0032] Figure 4a and Figure 4b It is the structural diagram of the cooling blade of the traditional DC clapboard. The partition plate 3 divides the channel into multiple cooling chambers 4, the cold air flows in from the blade root 5, then flows along the cooling chamber 4 to the blade tip 6, part of it flows out from the blade tip 6, and part of it passes through the gap between the partition plate 3 and the blade tip 6. The hole flows to the exhaust slot 7 on the trailing edge and flows out from the exhaust slot 7 .

[0033] Figure 5a and Figure 5b It is a schematic diagram of filling the grid structure in the cooling blade of the traditional DC baffle. The filling of the grid structure 8 does not change the design of the cooling blade flow channel, but only fills in the cooling cavity 4 formed by the partition plate 3, and the cold air flow direction does not change, and will still flow in the direction of the arrow marked in FIG. 4 . The wall thickness of the airf...

Embodiment 3

[0035] Fig. 6 is a schematic diagram of the grid structure filled in the interior part of the cooling blade of the traditional DC separator. The wall thickness of the airfoil is 1 mm, the internal space of the airfoil is 3-8 mm, and the grid structure 9 is filled in the inner wall of the airfoil and the side wall of the diversion partition. The thickness of the filled grid structure is 1 mm, and the periodic size of the substructure is 1 mm. The filling of the grid structure 9 does not change the flow channel design of the cooling blade, and the flow direction of the cold air does not change, and will still flow in the direction of the arrow marked in FIG. 4 . When the cold air flows through the flow channel, because the grid structure is only partially filled, the pressure drop of the cold air flow rate is less affected; at the same time, the filling height of the grid structure is equivalent to the height of the spoiler fins originally designed by the blade, which can destro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com