Intensified heat exchange tube provided with spiral grooved tube with spiral fin inserted inside

A technology of spiral finned tubes and spiral fins, which is applied in the field of enhanced heat transfer and heat transfer tubes, can solve problems such as flow resistance limits, and achieve the effects of small flow resistance, enhanced turbulence, and improved heat transfer coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

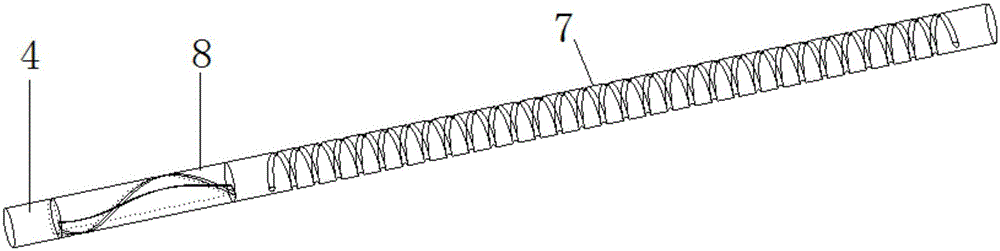

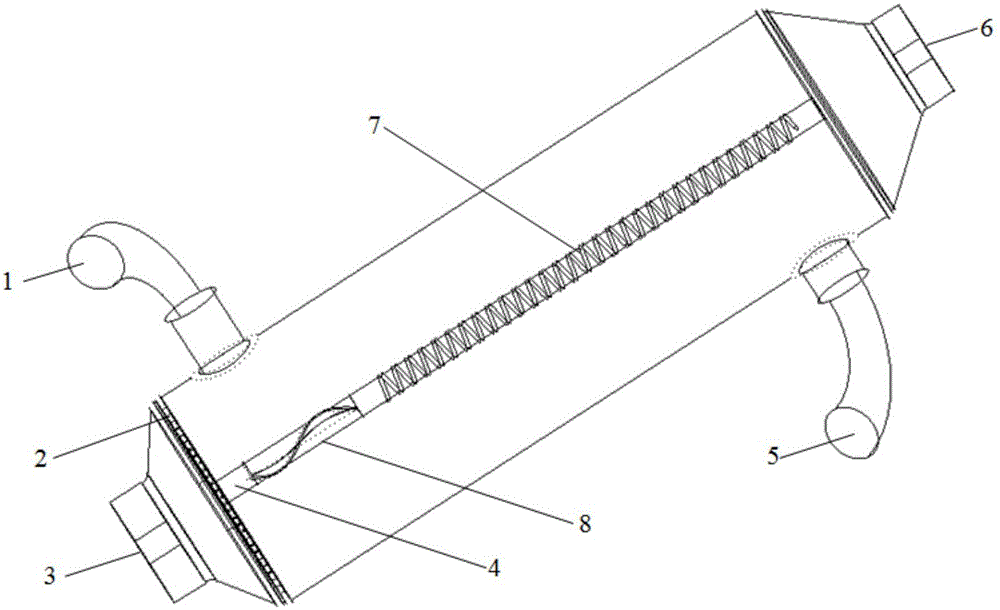

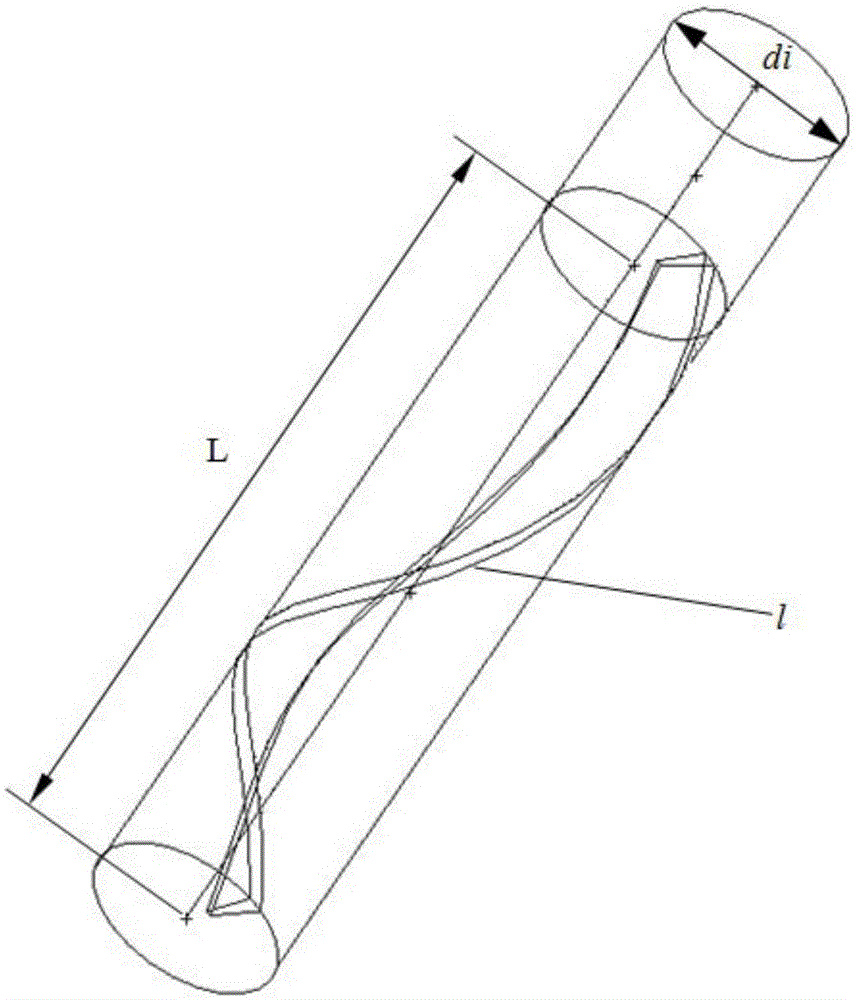

[0015] Such as figure 1 As shown, the enhanced heat exchange tube of the present invention with inserted spiral-finned and spiral-grooved tubes includes reserved smooth tubes 4, spiral-finned tubes 8 and spiral-grooved tubes 7 connected in sequence, and the joints are sealed. The reserved light pipe 4 is used to install the enhanced heat exchange tube on cooling equipment such as EGR cooler, and communicates with the inlet 3 of the cooled medium of the cooling equipment; both the spiral finned tube 8 and the spiral grooved tube 7 are used to enhance the turbulence , enhanced heat exchange; the present invention introduces the spiral finned tube 8 on the basis of the spiral grooved tube 7, reduces the flow resistance, and enhances the turbulence effect.

[0016] As a common technical means in this field, the inner wall surface of the spiral grooved pipe 7 is composed of one or more combinations of smooth surface, spiral groove surface and rib wall surface. The outer wall surfa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com