Control method of soybean milk machine

A control method and technology for a soymilk machine, applied in the control field of soymilk machine, can solve the problems of more heat accumulation, deviation, uneven heating, etc., and achieve the effect of uniform slurry temperature, saving pulping cycle, and reducing thermal inertia.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] A control method for a soybean milk machine, such as figure 1 As shown, the method includes step S11:

[0040] S11. During the heating process of the soybean milk machine, the motor is controlled to stir the slurry; wherein, the rotation speed of the motor changes with the temperature of the slurry.

[0041] In the embodiment of the present invention, the motor is controlled to agitate at the speed M while heating during the pulping process of the soybean milk machine. The speed of rotation can save crushing time, shorten the pulping cycle, and at the same time reduce the intensity of heat convection during heating and reduce the generation of heating inertia.

[0042] In the embodiment of the present invention, when the pulping process of the soybean milk machine includes: a heating stage, a crushing stage and a boiling stage, the motor can be controlled to stir the slurry during the heating stage.

[0043] In the embodiment of the present invention, the synchronous ...

Embodiment 2

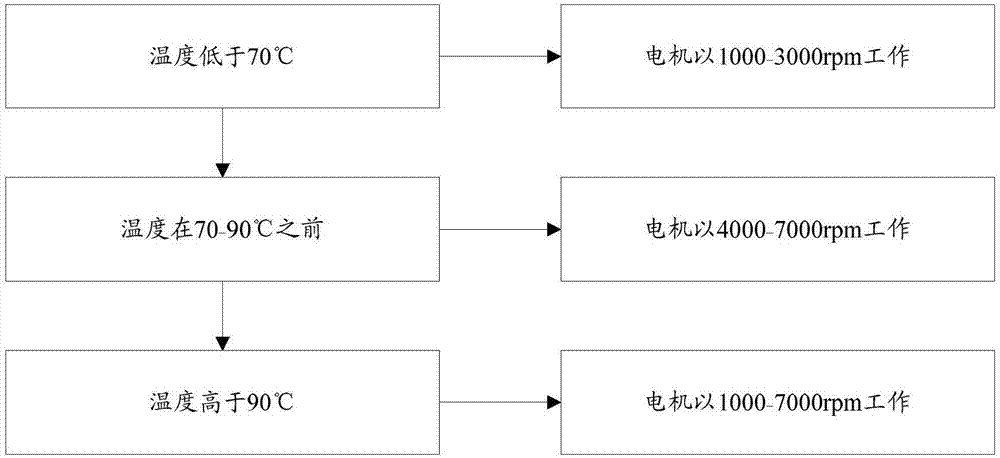

[0047] In this embodiment, on the basis of the first embodiment, the rotational speed M of the synchronous motor is further limited.

[0048] Optionally, the variation of the rotational speed of the motor with the slurry temperature may include:

[0049] When the slurry temperature is less than a preset temperature threshold, the motor speed is less than a preset first speed;

[0050] When the slurry temperature is greater than or equal to the temperature threshold, the rotational speed of the motor is less than a preset second rotational speed;

[0051] Wherein, the second rotational speed is greater than the first rotational speed.

[0052]Optionally, the temperature threshold may include: 65°C-75°C;

[0053] The first rotational speed may include: 2500-3500 rpm;

[0054] The second rotational speed may include: 6500-7500 rpm.

[0055] In the embodiment of the present invention, when the slurry temperature is low, for example, when the slurry temperature is less than 70°...

Embodiment 3

[0073] This embodiment further limits the working mode of the motor on the basis of the first and second embodiments.

[0074] Optionally, the method also includes:

[0075] During the heating process of the soymilk machine, when the slurry temperature reaches the preset anti-collision temperature, confirm that the pulping process of the soymilk machine enters the anti-collision stage; and in the anti-collision stage, control the heating device to reduce the heating power, and control the motor to reduce the speed and / or or change the way you work.

[0076] In the embodiment of the present invention, when the pulping process of the soymilk machine includes: a heating stage, a crushing stage and a boiling stage, the anti-collision stage generally appears before the crushing stage as a sign of entering the crushing stage. In the anti-collision stage, reduce the heating power and heat the slurry with a small power, so that the height of the slurry foam will rise slowly with the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com