Super cavitation method and device with introduced hot steam for underwater high speed navigating equipment

A technology of superheated steam and superheated steam, applied in transportation and packaging, hull, hull design, etc., can solve problems such as helpless natural cavitation, and achieve the effect of increasing the speed of the aircraft body and reducing frictional resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Preferred embodiments of the present invention are described in detail as follows in conjunction with accompanying drawings:

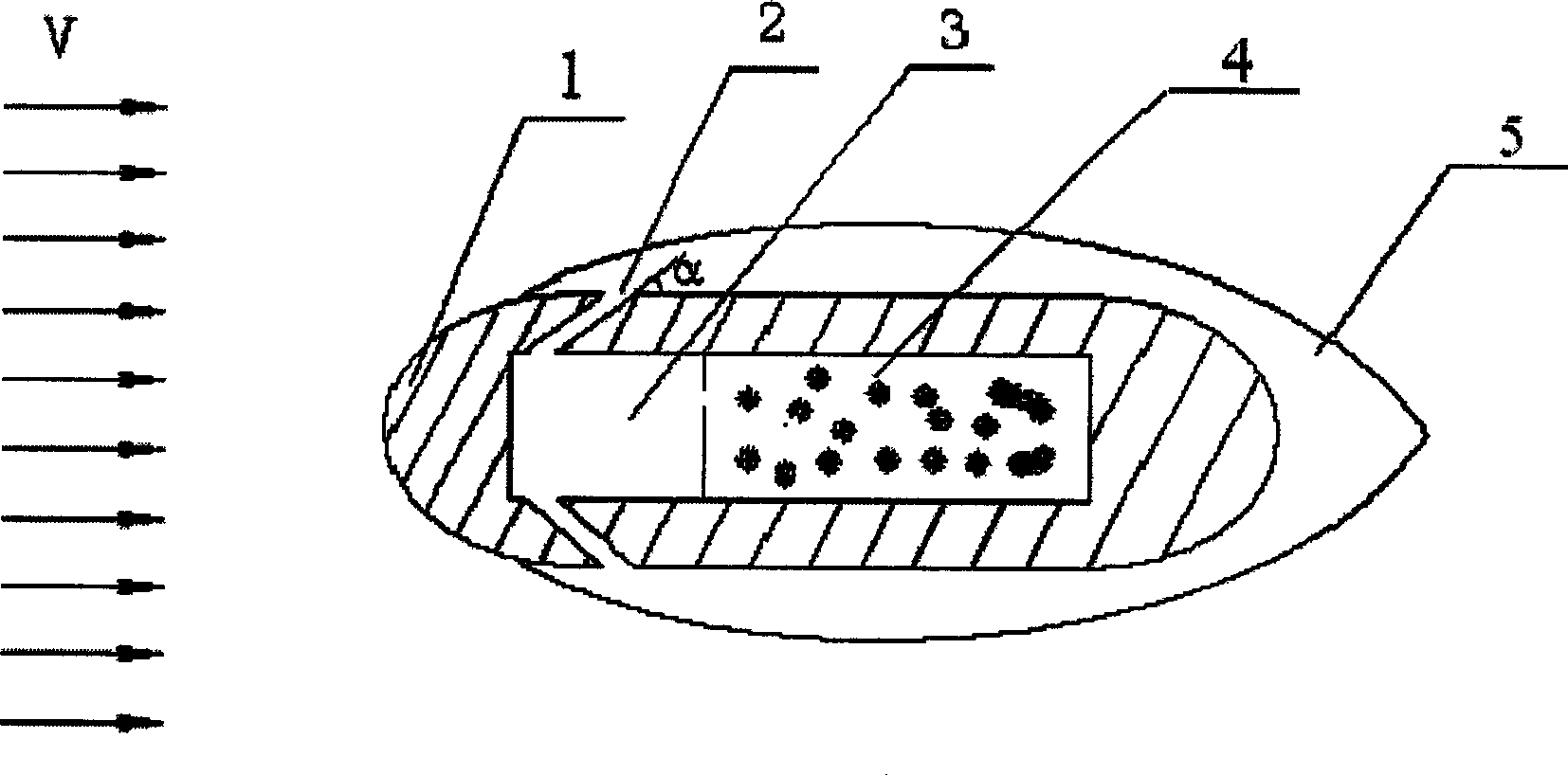

[0018] The method of introducing superheated steam into the underwater high-speed aircraft body to cause supercavitation is to use heating to vaporize water into superheated steam, and then pass the superheated steam into the cavitation around the aircraft body to promote the natural environment around the high-speed aircraft body. Cavitation and natural cavitation are transformed into supercavitation, and supercavitation with good stability is obtained, thereby greatly reducing the frictional resistance on the surface of the underwater aircraft body and increasing the speed of the aircraft body. The heating method is a heating method using high-temperature gas, or solid fuel, or liquid hydrogen+liquid oxygen, electricity, microwave or electromagnetic heating. The temperature of the superheated steam is 0.01-1000 degrees Celsius higher than the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com