Continuous microwave drying method and device of nanometer fiber membrane

A nanofiber membrane, microwave drying technology, applied in progressive dryers, drying gas layout, lighting and heating equipment, etc., can solve problems such as poor ventilation capacity of equipment, affecting material properties, overheating, etc., to achieve fast drying speed, consumption Little energy, little damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

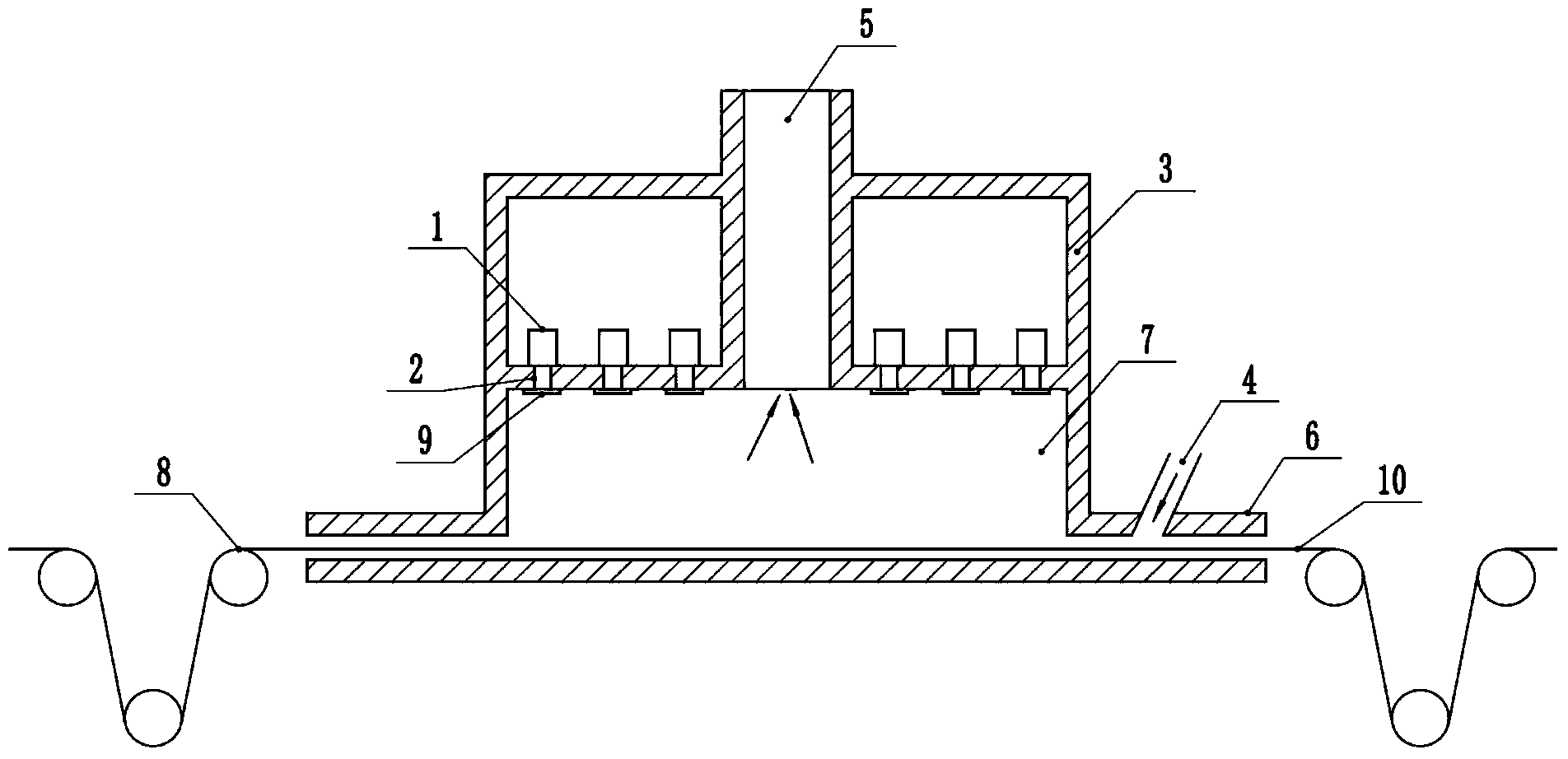

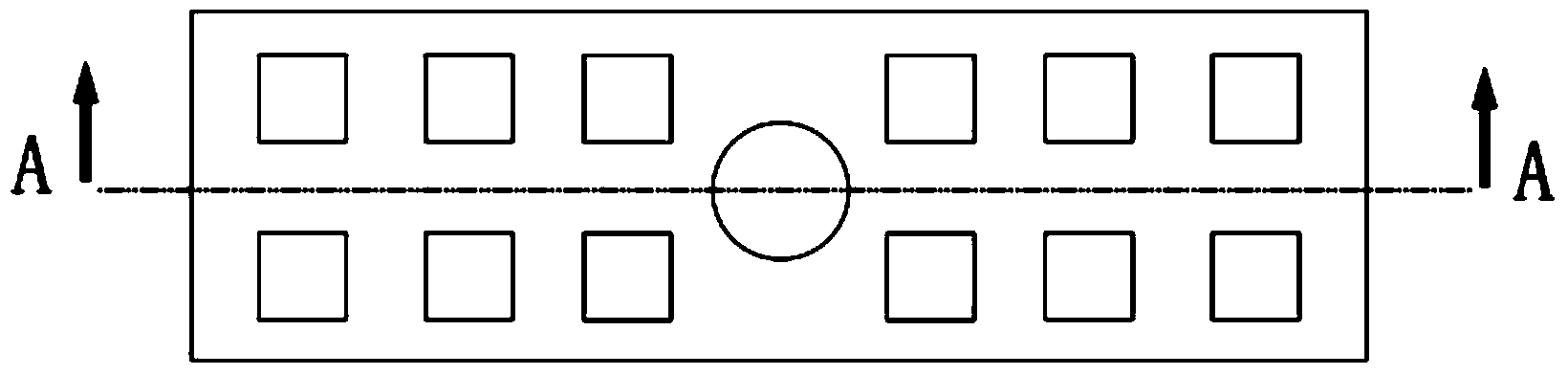

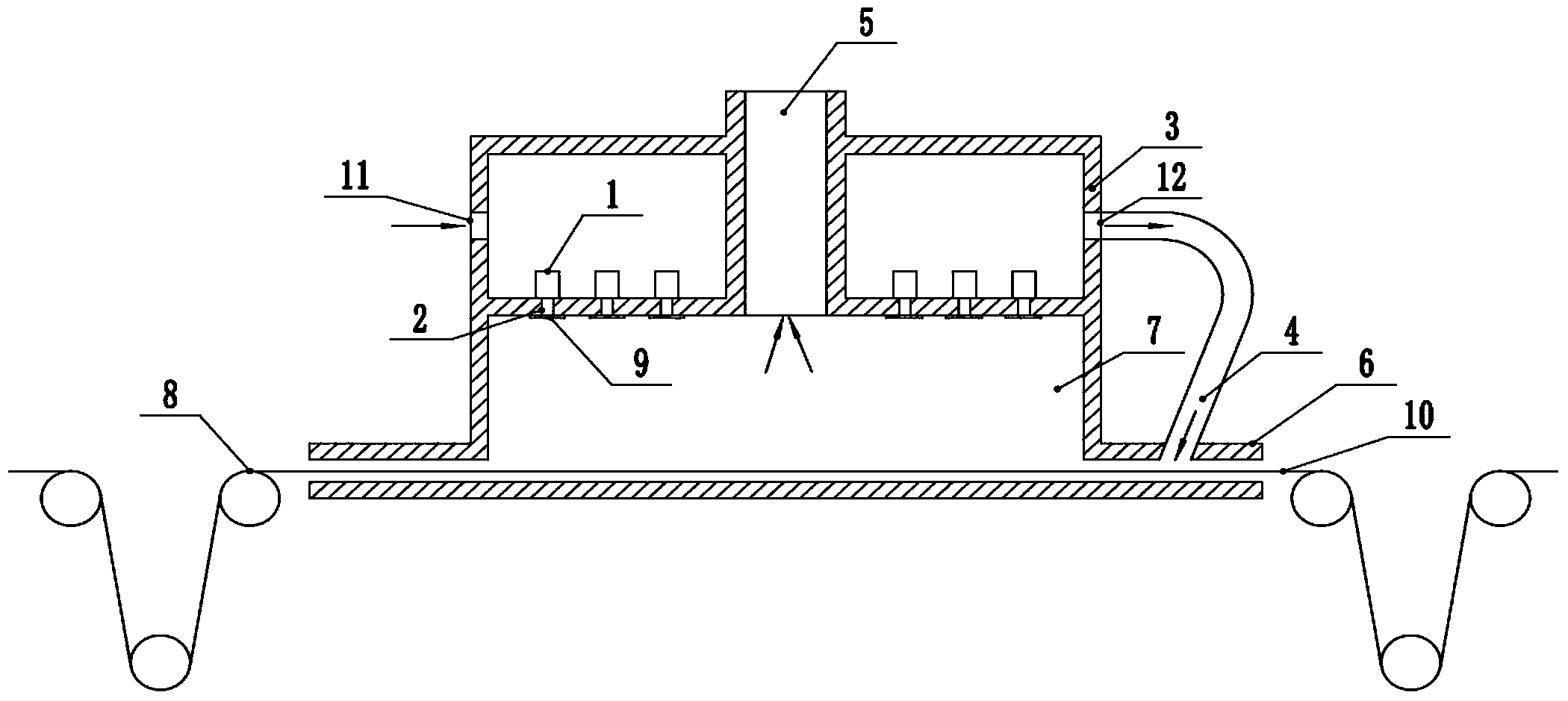

Method used

Image

Examples

Embodiment 1

[0043] Using polyethylene terephthalate (PET) non-woven fabric as the electrospinning collection matrix, with 10wt% polyvinyl alcohol (PVA) / water (H 2 O) solution electrospinning obtains PVA / PET nanofiber film, because also contains H in the nanofiber film 2 O, it needs to be dried. Ordinary air blast drying treatment tends to make both sides of the film curl and the surface is uneven.

[0044] Microwave heating has better selectivity and faster drying rate. The dielectric constant of water is about 80, the dielectric loss is about 0.2, and it has a strong absorption of microwaves. The dielectric constant and dielectric loss of PVA / PET are small, the absorption of microwave is very weak, and it is basically not heated in the microwave field. The water molecules are very easy to absorb microwaves, and local short-term heating can be realized to make the water molecules escape quickly and overflow, while the remaining water is discharged by blast drying. Adopting the microwav...

Embodiment 2

[0047] Using polypropylene (PP) non-woven fabric as the electrospinning collection matrix, the PAN / PP nanofiber membrane was obtained by electrospinning with 10wt% polyacrylonitrile (PAN) / dimethyl sulfoxide (DMSO) solution. It also contains DMSO solvent, which needs to be dried. Ordinary air blast drying treatment will easily make both sides of the film curl and the surface will be uneven.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com