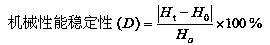

Edible composite membrane with stable mechanical properties and preparation method thereof

A technology of mechanical properties and composite film, which is applied in the field of soybean protein isolate/gelatin/k-carrageenan composite packaging film and its preparation, can solve the problems of decreased shelf life of packaged food, poor mechanical performance stability, etc., and achieves good mechanical performance stability. , Long-lasting mechanical properties and smooth surface morphology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] Example 1 A kind of preparation method of edible composite film with stable mechanical properties

[0051] (1) Add 100g of distilled water at a temperature of 40~60°C to the beaker, add 5% gelatin and 1% k-carrageenan in terms of weight percentage of distilled water, add 4~8% absolute ethanol after the two kinds of glue absorb water and swell, 1.0% plasticizer, 0.05~0.15% anhydrous sodium sulfite, add 2% soybean protein isolate under the state of magnetic stirring to obtain a mixed solution;

[0052] (2) Adjust the pH value of the solution to 8.0, stir with a magnetic stirrer for 45-50 seconds, heat in a water bath at 90-95°C for 20-25 minutes, and use ultrasonic waves for defoaming and degassing treatment. Ultrasonic conditions: 100-150 Hz, time 20 minutes , pour the degassed solution into the acrylic plate tank;

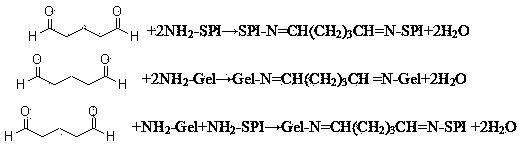

[0053] (3) Put the glutaraldehyde liquid into a closed steam cross-linking device with automatic temperature and pressure control, and carry out the glut...

Embodiment 2

[0058] (1) Add 100g of distilled water at a temperature of 40~60°C to the beaker, add 7% gelatin and 3% k-carrageenan in terms of weight percentage of distilled water, add 4~8% absolute ethanol after the two kinds of glue absorb water and swell, 3.0% plasticizer, 0.05~0.15% anhydrous sodium sulfite, add 3% soybean protein isolate under the state of magnetic stirring to obtain a mixed solution;

[0059] (2) Adjust the pH value of the solution to 8.0, stir with a magnetic stirrer for 45-50 seconds, heat in a water bath at 90-95°C for 20-25 minutes, and use ultrasonic waves for defoaming and degassing treatment. Ultrasonic conditions: 100-150 Hz, time 20 minutes , pour the degassed solution into the acrylic plate tank;

[0060] (3) Put the glutaraldehyde liquid into a closed steam cross-linking device with automatic temperature and pressure control, and carry out the glutaraldehyde steam cross-linking reaction in the closed steam cross-linking device. The specific reaction condit...

Embodiment 3

[0066] (1) Add 100g of distilled water at a temperature of 40~60°C to the beaker, add 6.5% gelatin and 2% k-carrageenan in terms of weight percentage of distilled water, add 4~8% absolute ethanol, 1.8% plasticizer, 0.05~0.15% anhydrous sodium sulfite, add 4% soybean protein isolate under the state of magnetic stirring to obtain a mixed solution;

[0067] (2) Adjust the pH value of the solution to 8.0, stir with a magnetic stirrer for 45-50s, heat in a water bath at 90-95°C for 20-25min, and use ultrasonic waves for defoaming and degassing treatment. Ultrasonic conditions: 120 Hz, time 20 min, Pour the degassed solution into the acrylic plate tank;

[0068] (3) Put the glutaraldehyde liquid into a closed steam cross-linking device with automatic temperature and pressure control, and carry out the glutaraldehyde steam cross-linking reaction in the closed steam cross-linking device. The specific reaction conditions: the internal pressure of the steam cross-linking device Constan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com