Device and production technology for treating ternary-monomer wastewater and extracting sodium sulfate

A technology of sodium sulfate and three monomers, applied in the field of chemical production wastewater treatment, can solve the problems of increasing treatment difficulty, increasing project investment, reducing resin adsorption capacity, etc., achieving improved treatment capacity and anti-clogging performance, and strong adaptability to operating conditions , the effect of increasing the effective area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

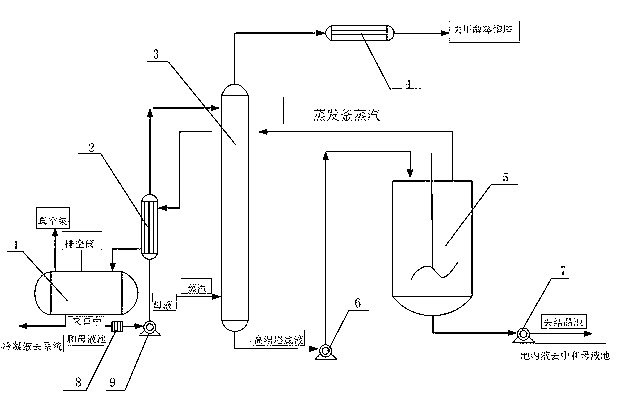

[0049] Example 1, such as figure 1 As shown, a device for treating three-monomer waste water and extracting sodium sulfate includes a plate-and-frame filter press 8, a mother liquor heat exchanger 2, a stripping tower 3 and a condenser 4 connected through pipelines in sequence, and the condenser 4 passes through The pipeline is connected with a methanol distillation tower.

[0050] The mother liquid heat exchanger 2 is also connected with a vacuum receiving tank 1 through a pipeline, and the vacuum receiving tank 1 is connected with a vacuum pump, and an emptying valve is installed on the vacuum receiving tank 1 .

[0051] A flushing port is installed in the material inlet and outlet pipelines of the mother liquid heat exchanger. The mother liquid heat exchanger has been used for about three months, and the on-line flushing is carried out to remove the materials in the tubes without dismantling the equipment. It only takes 4 hours to stop production and clean. Maintenance is ...

Embodiment 2

[0068] Example 2, such as figure 1 As shown, a device for treating three-monomer waste water and extracting sodium sulfate includes a plate-and-frame filter press 8, a mother liquor heat exchanger 2, a stripping tower 3 and a condenser 4 connected through pipelines in sequence, and the condenser 4 passes through The pipeline is connected with a methanol distillation tower.

[0069] The mother liquid heat exchanger 2 is also connected with a vacuum receiving tank 1 through a pipeline, and the vacuum receiving tank 1 is connected with a vacuum pump, and an emptying valve is installed on the vacuum receiving tank 1 .

[0070] A flushing port is installed in the material inlet and outlet pipelines of the mother liquid heat exchanger. The mother liquid heat exchanger has been used for about three months, and the on-line flushing is carried out to remove the materials in the tubes without dismantling the equipment. It only takes 4 hours to stop production and clean. Maintenance is ...

Embodiment 3

[0087] Example 3, such as figure 1 As shown, a device for treating three-monomer waste water and extracting sodium sulfate includes a plate-and-frame filter press 8, a mother liquor heat exchanger 2, a stripping tower 3 and a condenser 4 connected through pipelines in sequence, and the condenser 4 passes through The pipeline is connected with a methanol distillation tower.

[0088] The mother liquid heat exchanger 2 is also connected with a vacuum receiving tank 1 through a pipeline, and the vacuum receiving tank 1 is connected with a vacuum pump, and an emptying valve is installed on the vacuum receiving tank 1 .

[0089] A flushing port is installed in the material inlet and outlet pipelines of the mother liquid heat exchanger. The mother liquid heat exchanger has been used for about three months, and the on-line flushing is carried out to remove the materials in the tubes without dismantling the equipment. It only takes 4 hours to stop production and clean. Maintenance is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com