Cooling structure of high-pressure moving blade of turbine of gas turbine

A technology of gas turbine and cooling structure, which is applied to the supporting elements of blades, machines/engines, mechanical equipment, etc., can solve the problems of increased cold air flow resistance, reduced cold air cooling capacity, small chamber area, etc., and achieves uniform temperature field. Low cold air flow, easy to manufacture effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0069] This embodiment is a cooling structure for the first-stage moving blade of a heavy-duty gas turbine turbine.

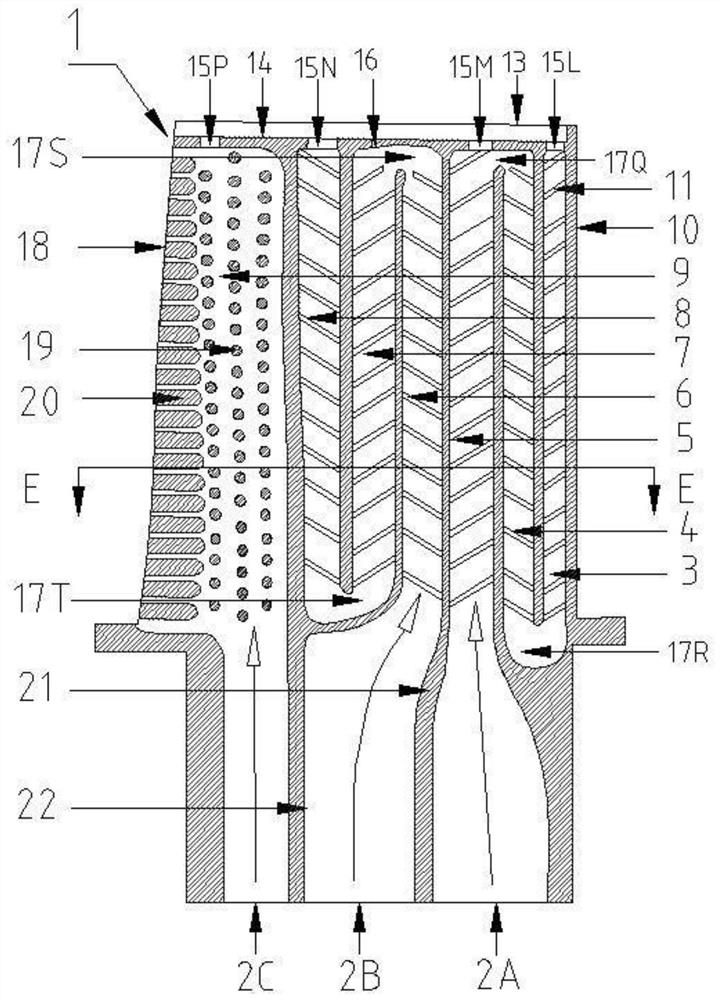

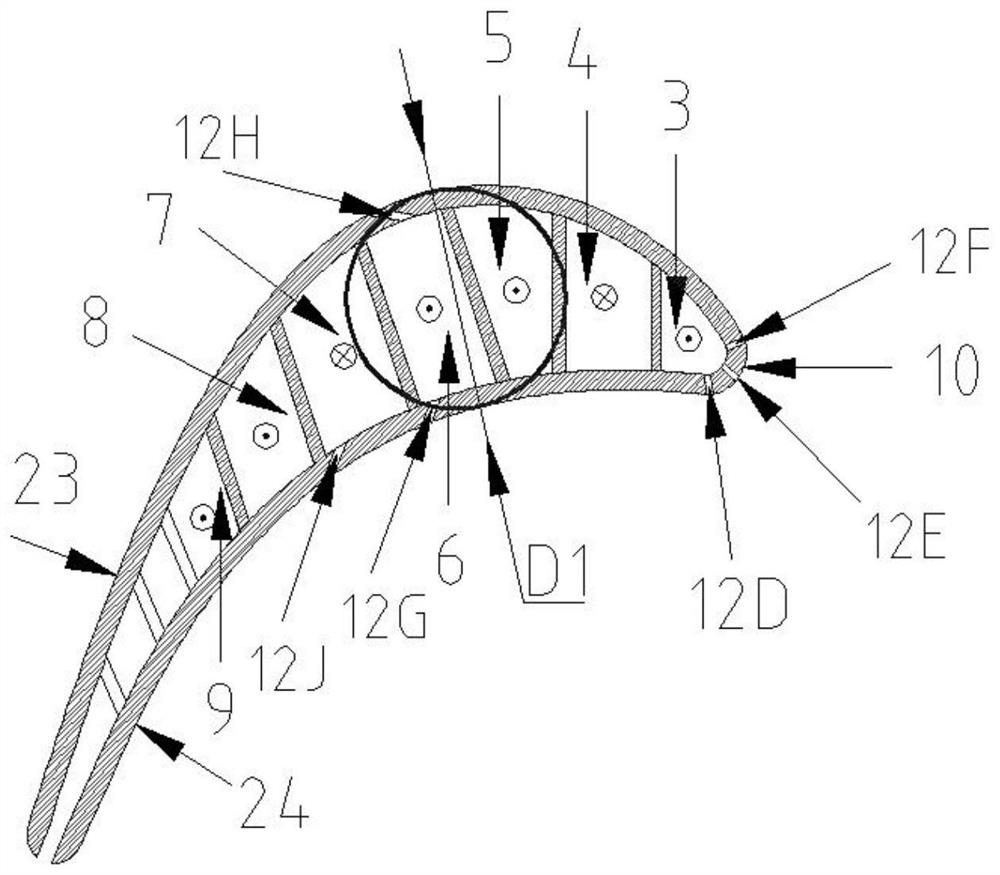

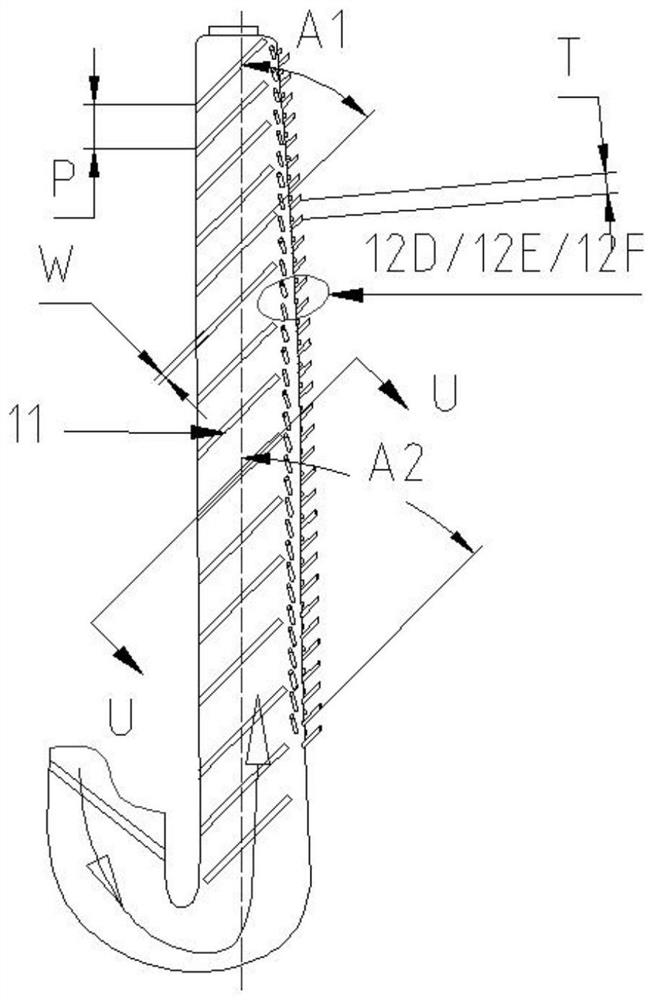

[0070] refer to figure 1 and figure 2 , is the front view and left view of the cooling structure of the first-stage rotor blade of a gas turbine turbine. In this embodiment, the height of the profile part of the blade is 5.50D1, the chord length is 4.05D1, and the axial chord length is 3.11D1, wherein D1 is the maximum thickness of the blade profile.

[0071] refer to figure 1 , there are three air inlets 2A, 2B and 2C at the bottom of the blade, and these three air inlets are evenly arranged at the root of the blade along the axial direction. The third channel, the second channel and the first channel are connected in sequence to form a serpentine channel, and the joints of adjacent channels form a U-shaped space; the fourth channel, the fifth channel and the sixth channel are connected in sequence to form a serpentine channel, adjacent A U-shaped space i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com