Conduction through type steam generator

A steam generator, straight-through technology, applied in the field of straight-through steam generators, can solve the problems of high installation costs, increased costs, and poor overall efficiency of the power station, saving investment costs, reducing pressure loss, and avoiding temperature skew. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

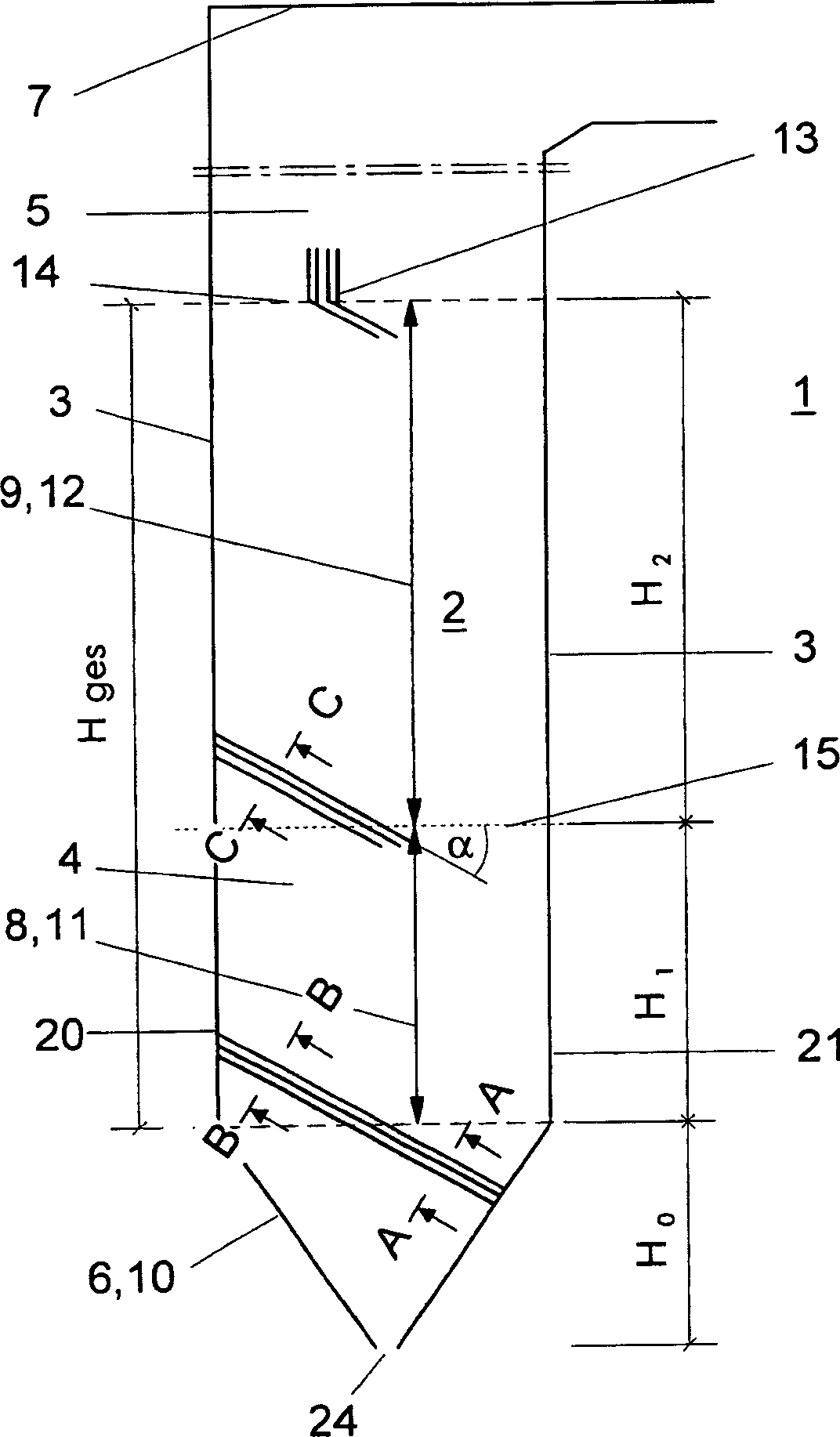

[0031] In fossil fuel-fired once-through steam generators 1 of conventional power stations, it is known that the working medium, usually water / steam, is preheated, evaporated, superheated in the channel or through-pass of the steam turbine circuit, and in the HD section of the steam turbine Intermediate superheating if required after internal partial decompression. The straight-through steam generator 1 is introduced below.

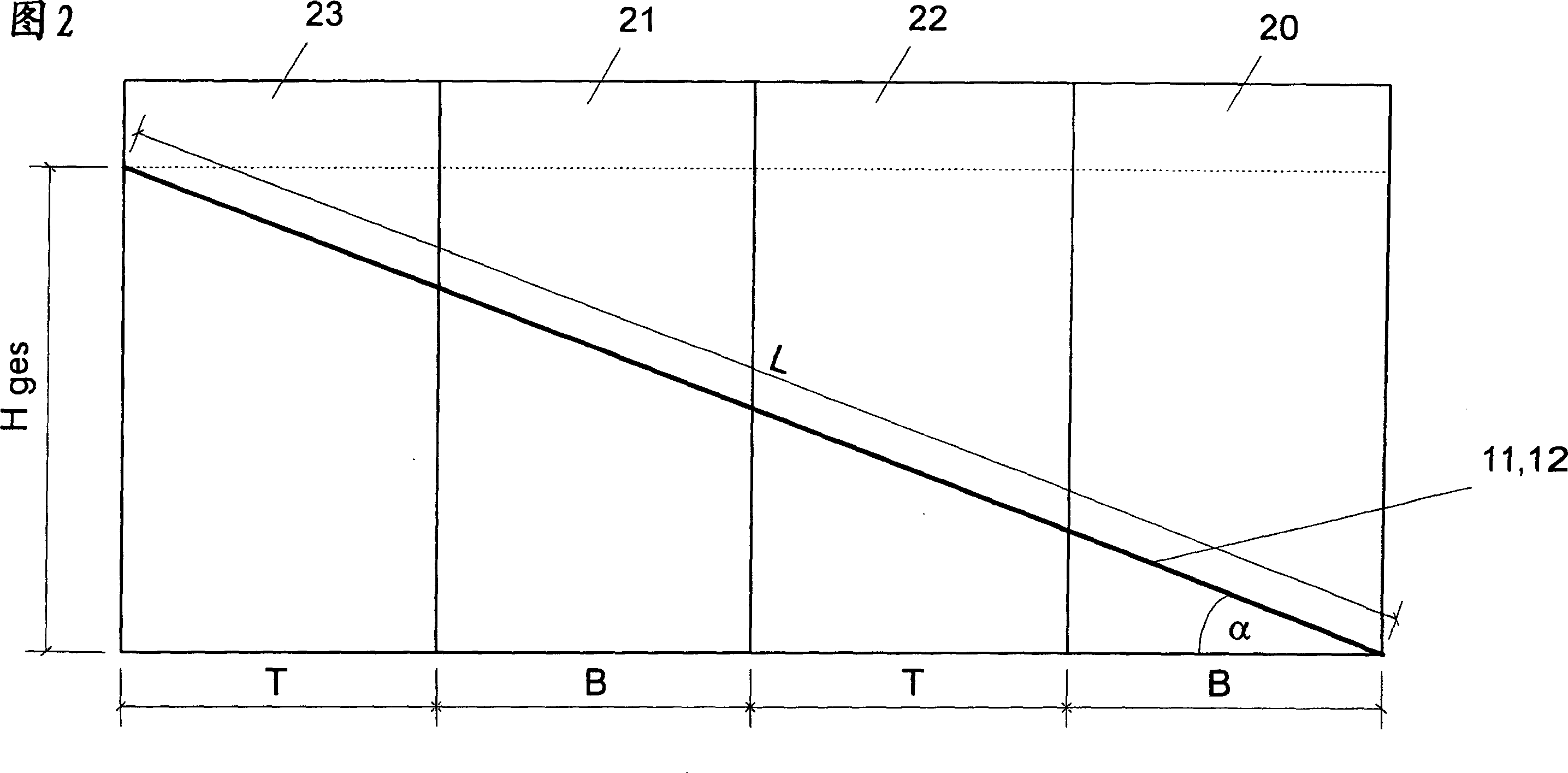

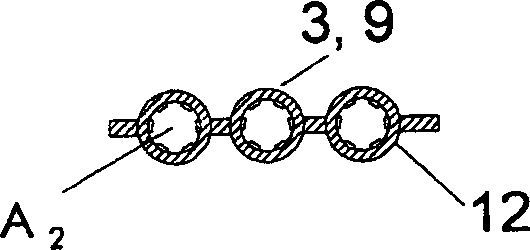

[0032] figure 1 A straight-through steam generator 1 is schematically shown with a vertical flue 2 formed by gas-tight tube walls 3 . The pipe wall 3 comprises in this respect the flue 2 of a rectangular cross-section preferably having a width B and a depth T, wherein, for example, the front wall and the rear wall 20, 21 of the flue 2 are on the width B and the right and left sides of the flue 2 The left side walls 22 , 23 extend over a depth T, see also FIG. 2 in this regard.

[0033] The flue 2 is divided into a lower part and an upper part 4,5. The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com