Injection molding machine for manufacturing a plurality of injection molding elements in period

A technology for injection molding machines and components, applied in the field of injection molding machines, which can solve problems such as strong cooling and slow cycle time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

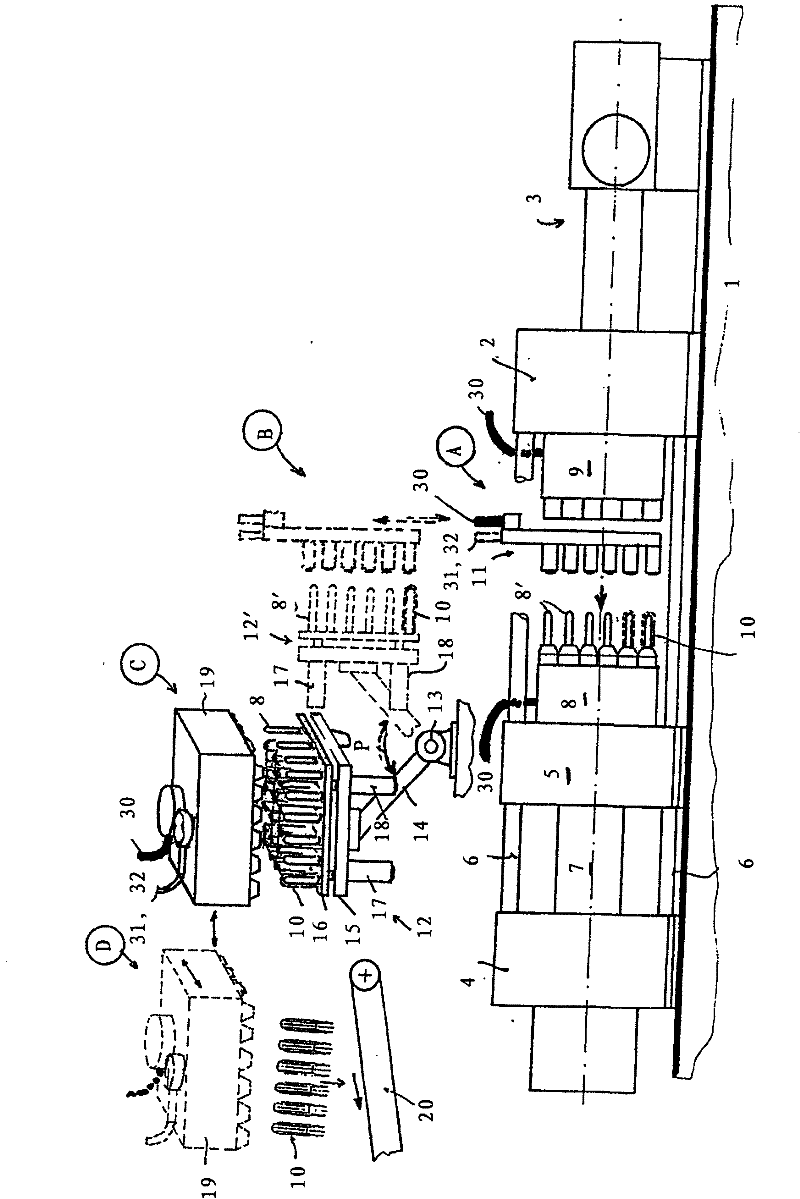

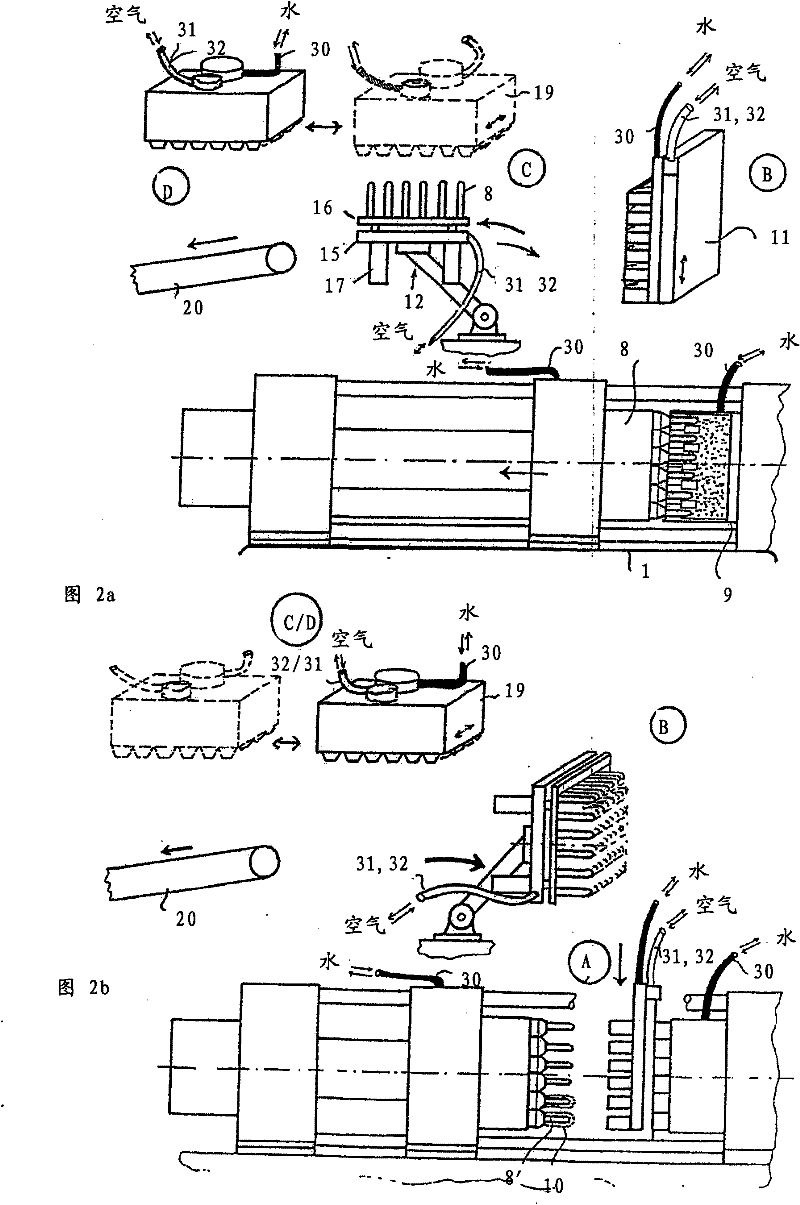

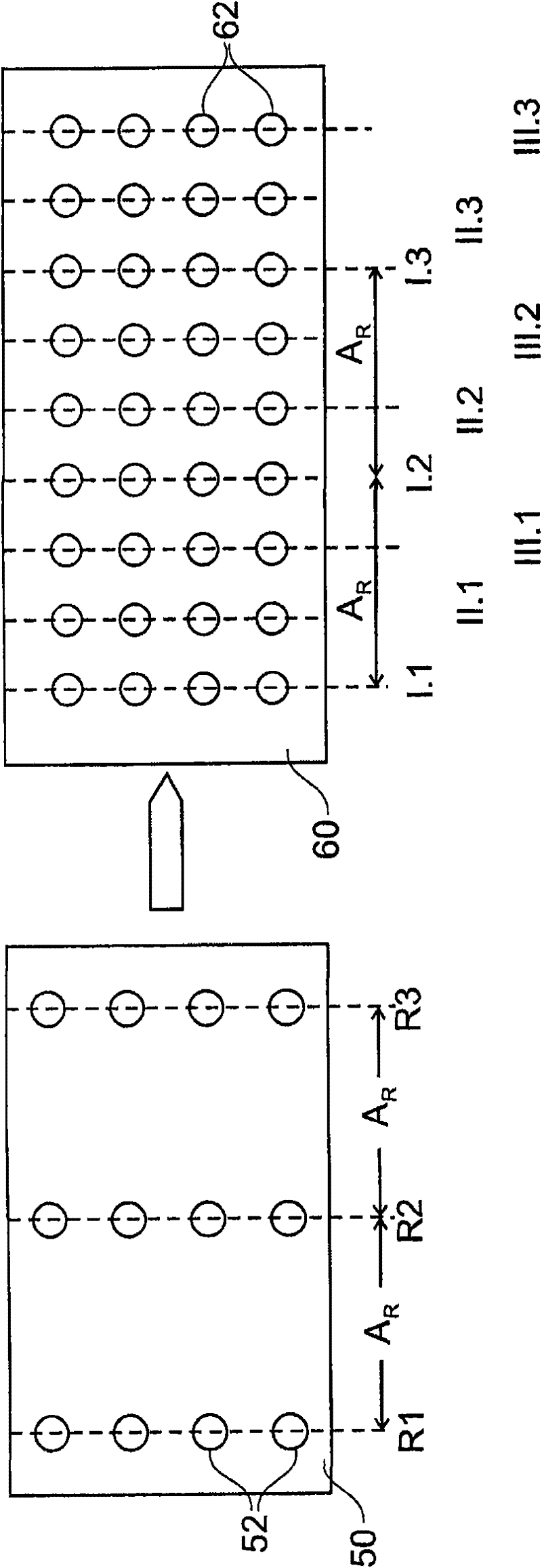

[0021] The embodiment of the invention is based on the known setup of a molding injection machine, which is arranged on a frame 1 . Here, a fixed profile fastening plate 2 is provided which forms an openable and closable clamping unit (Schliesseinheit) together with a mobile profile fastening plate 5 which is supported against a support plate 4 and is supported by The driving device 7 drives. Here the mobile profile fastening plate 5 moves along a draw bar 6 which absorbs the traction forces between the fixed support plate 2 and the support plate 4 . A mold half 9 is provided on the stationary profile fastening plate 2 and a further mold half 8 is provided on the mobile profile fastening plate 5 . This half-mold 8 has a plurality of cores 8', which together with the cavities of the half-mold 9 form a corresponding number of cavities during the joint movement of the clamping unit.

[0022] The plastic melt material (for example PET material) is injected via the mastication an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com