System and method for reducing friction in engines

A technology for internal combustion engines and vehicle systems, applied in the direction of engine components, machines/engines, charging systems, etc., can solve problems such as reducing fuel economy, increasing engine component resistance, increasing engine load, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

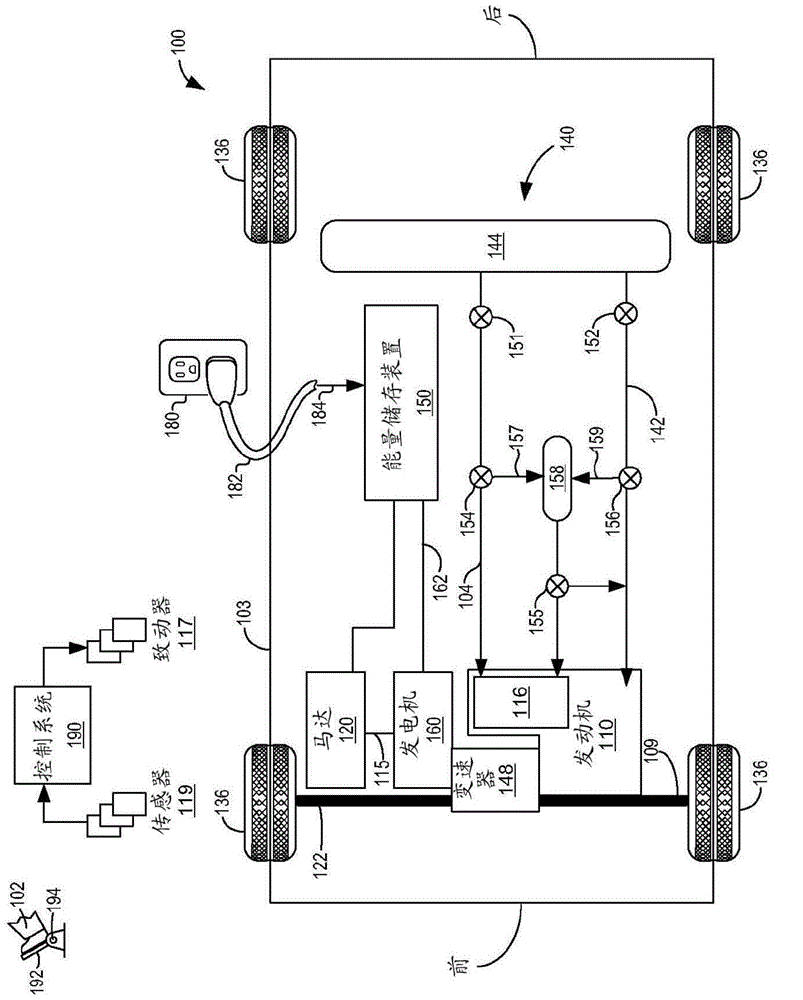

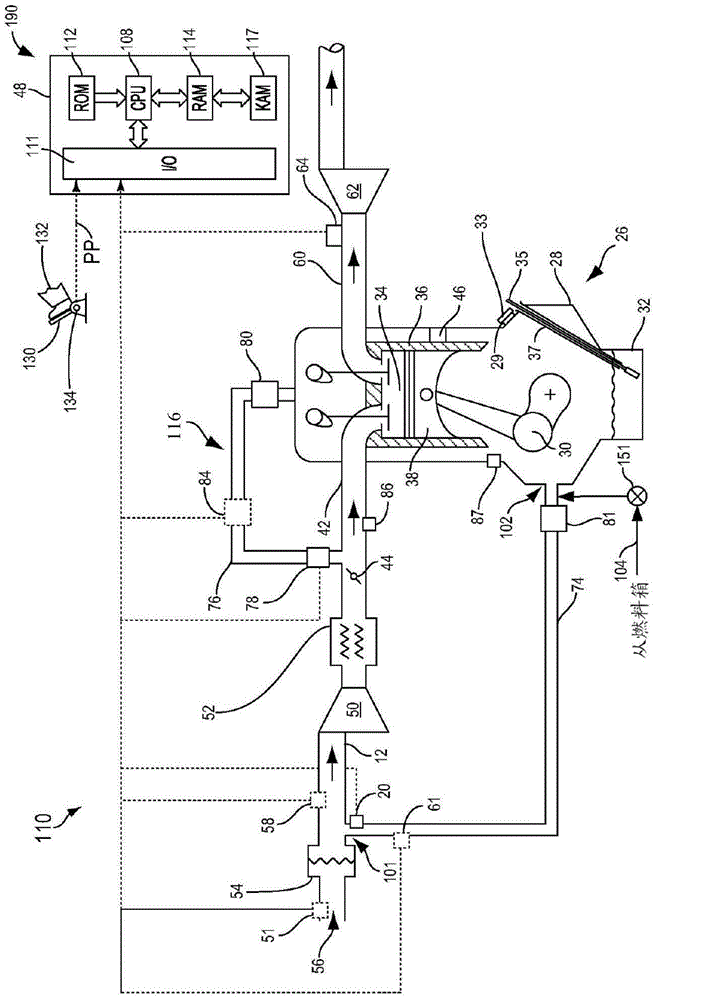

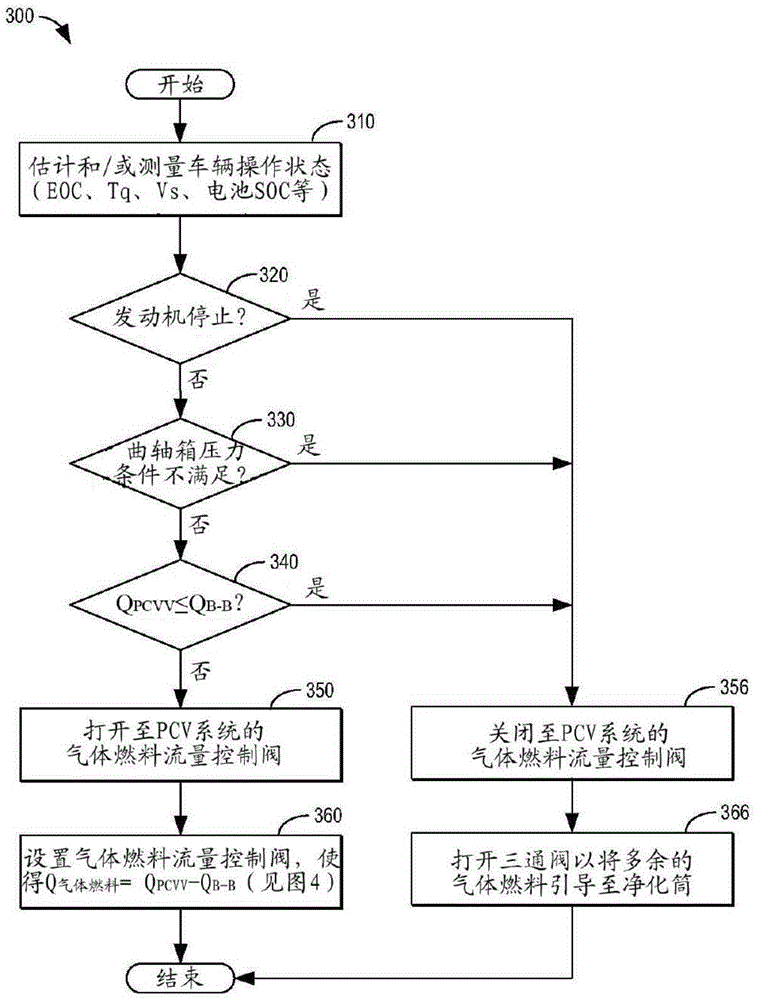

[0036] In the vehicle's propulsion system, the power loss caused by air resistance is proportional to the density of the gas or liquid in which the components rotate. Therefore, the power loss caused by air resistance can be reduced by reducing the density of the gas surrounding the transmission, electric motor, or generator in the box.

[0037] During the rotation, the friction between the components generates a lot of heat. To prevent the engine from overheating, this heat can be removed from the components and transferred to other places. This can be achieved by the cooling system during operation or the movement of the vehicle when the components are in contact with the cooler gas, which absorbs heat from the system and transfers the heat to the atmosphere or the cabin. Therefore, although the power loss is greatly reduced in the airless vacuum or low-pressure box, the cooling effect will be reduced or disappeared, resulting in engine degradation. Therefore, when determinin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com