Heat pump comprising a cooling device for cooling a guide space or a suction mouth

A technology of cooling equipment and suction port, which is applied in the field of heat pumps with cooling equipment for cooling the guide cavity or suction port, can solve the problems of small space, condenser size design restrictions, etc., achieve reliable operation of heat pumps, eliminate safety problems and corrosion problems, the effect of a reliable and stable heat pump

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

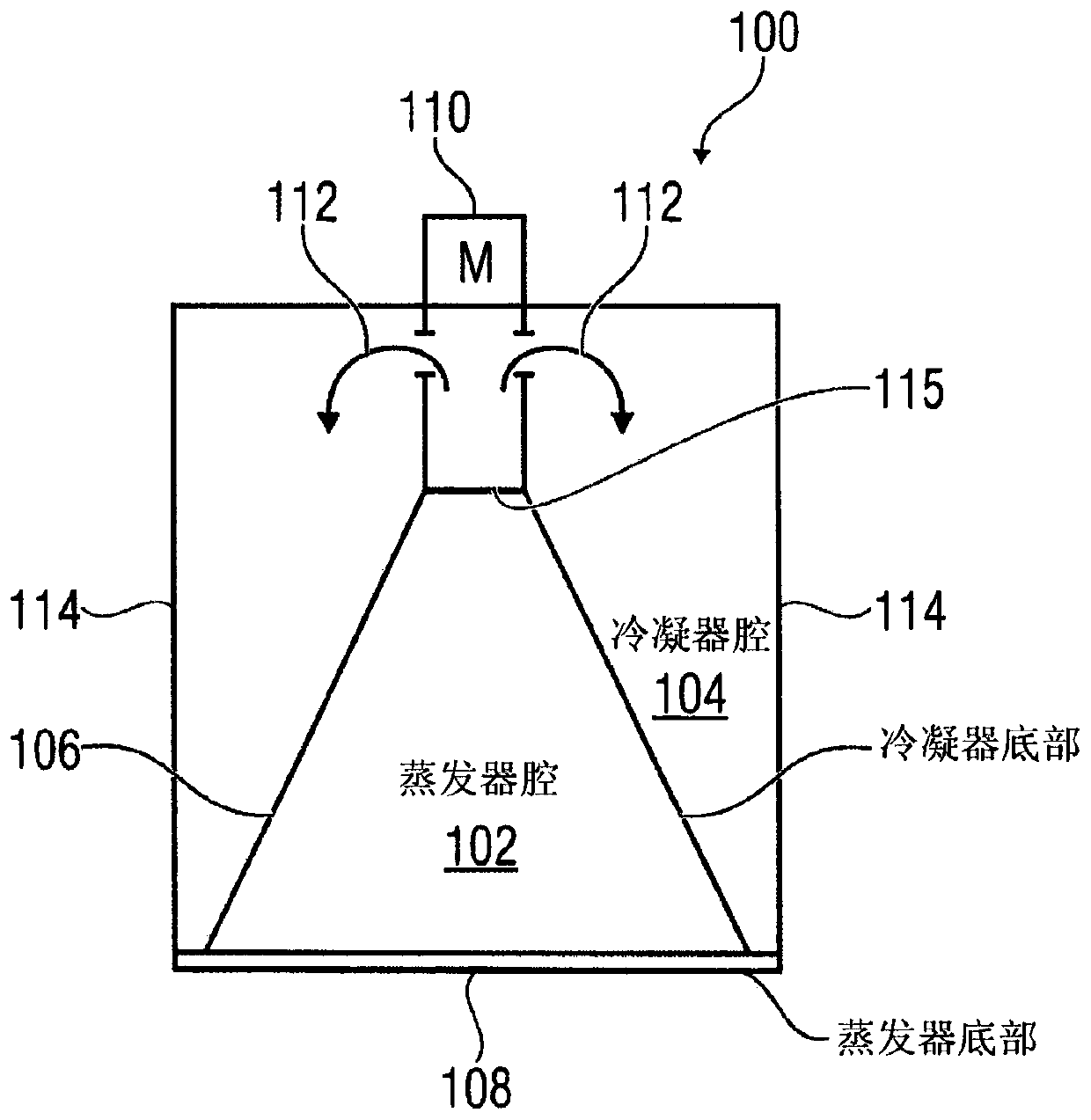

[0045] figure 1 Shown is a heat pump 100 having an evaporator for evaporating a working fluid in an evaporator chamber 102 . The heat pump also includes a condenser for liquefying evaporated working liquid in a condenser chamber 104 delimited by a condenser bottom 106 . as visible as a sectional view or as a side view figure 1 As shown, the evaporator cavity 102 is at least partially surrounded by the condenser cavity 104 . Furthermore, the evaporator chamber 102 is separated from the condenser chamber 104 by a condenser bottom 106 . Furthermore, the condenser bottom is connected to the evaporator bottom 108 so as to define the evaporator cavity 102 . In one implementation, a compressor 110 is located above the evaporator chamber 102 or at another location, the compressor at figure 1 Although not shown in detail, the compressor is designed in principle to compress the evaporated working fluid and to conduct it as compressed vapor 112 into the condenser space 104 . The con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com