Cooling plasma cutting systems and related systems and methods

A cutting system, plasma technology, applied in the direction of plasma, plasma welding equipment, modification of power electronics, etc., can solve the problems of system inefficiency, component/system failure, etc., and achieve the effect of efficient cooling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

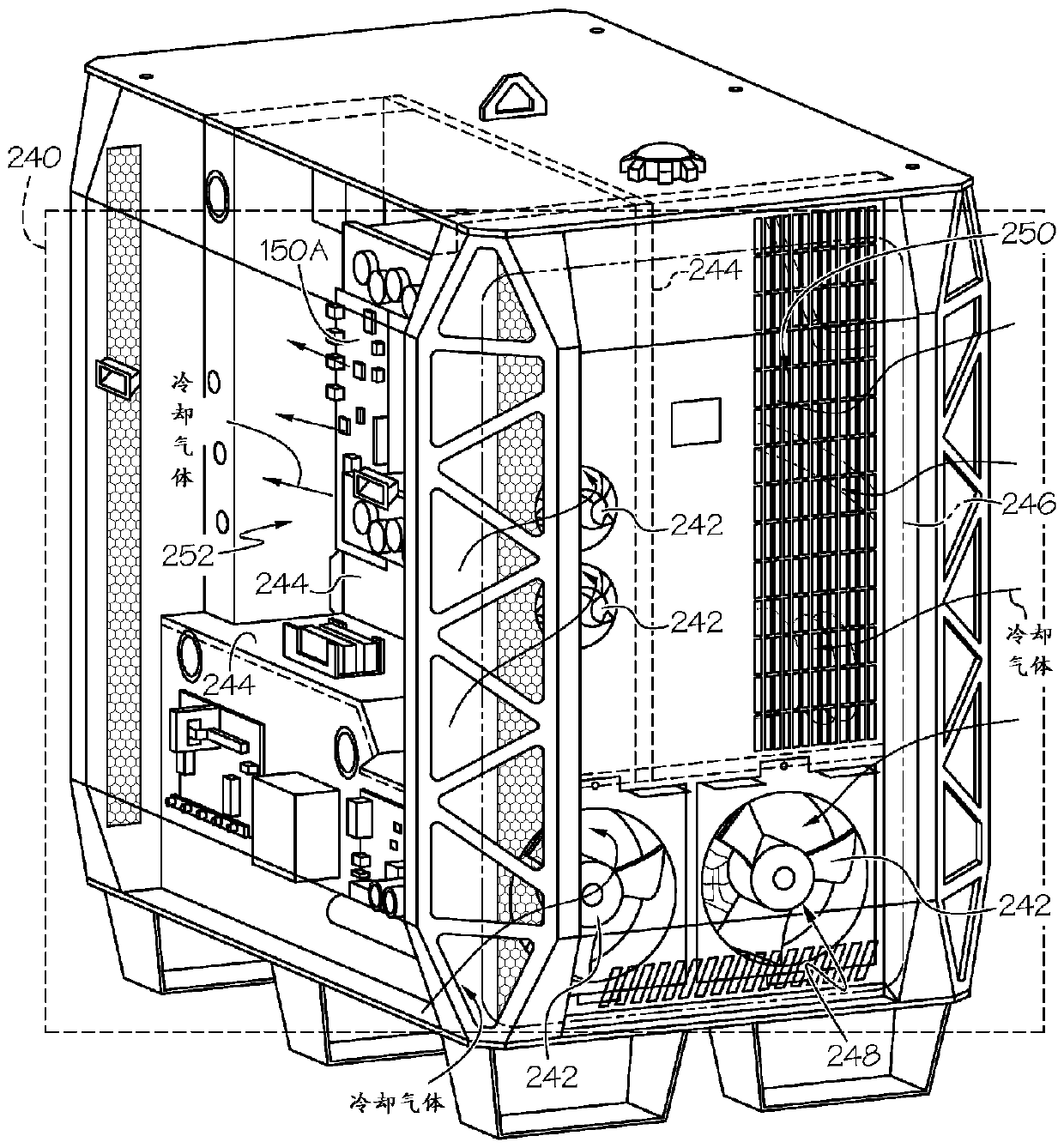

[0029] In some aspects, a plasma arc power supply may include multiple cooling circuits that each house sets of different types of components that may have different operating characteristics and cooling requirements. As such, different cooling circuits may be configured to provide different cooling flows so that different components may be cooled at different (eg, tailored) cooling rates.

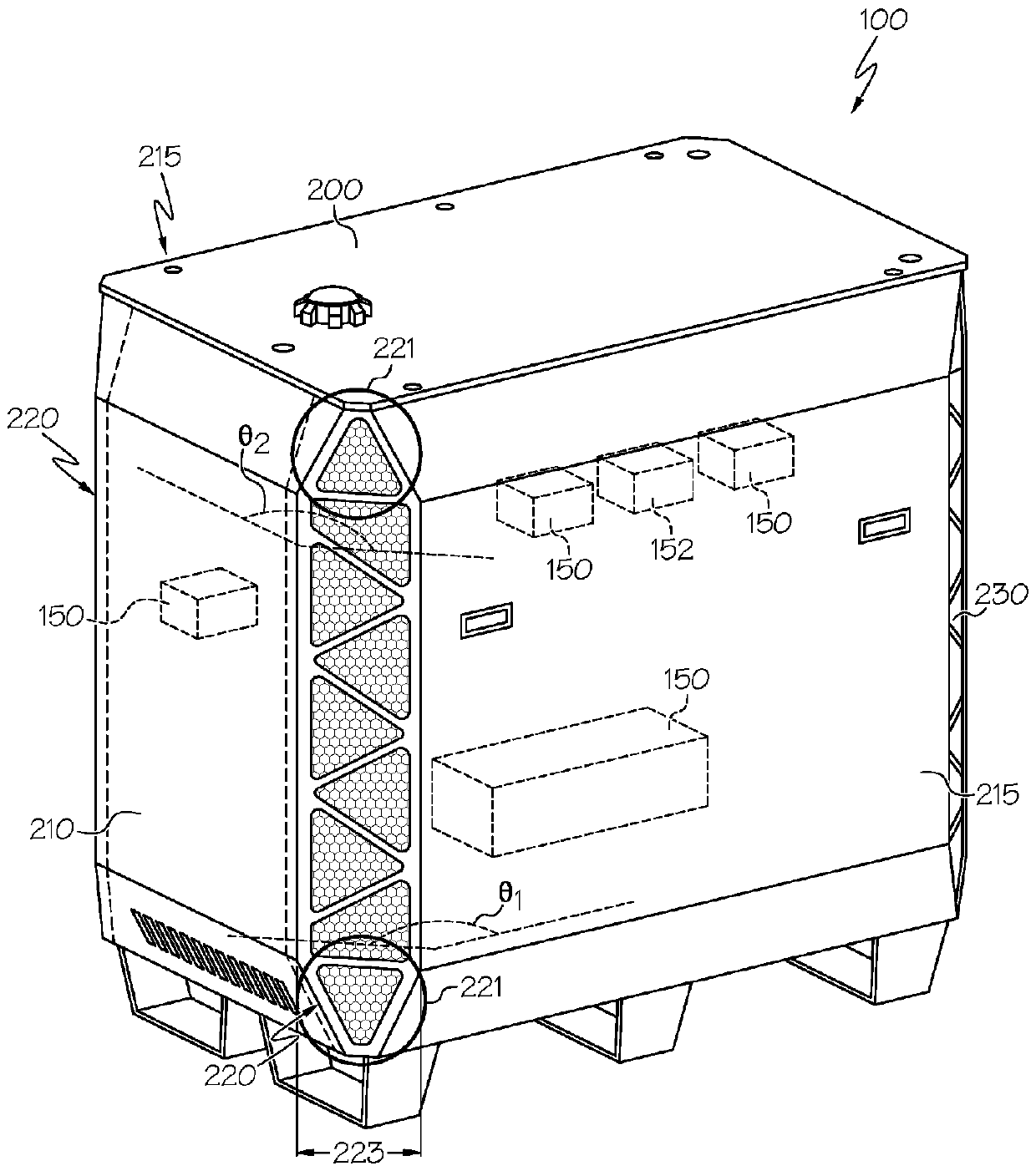

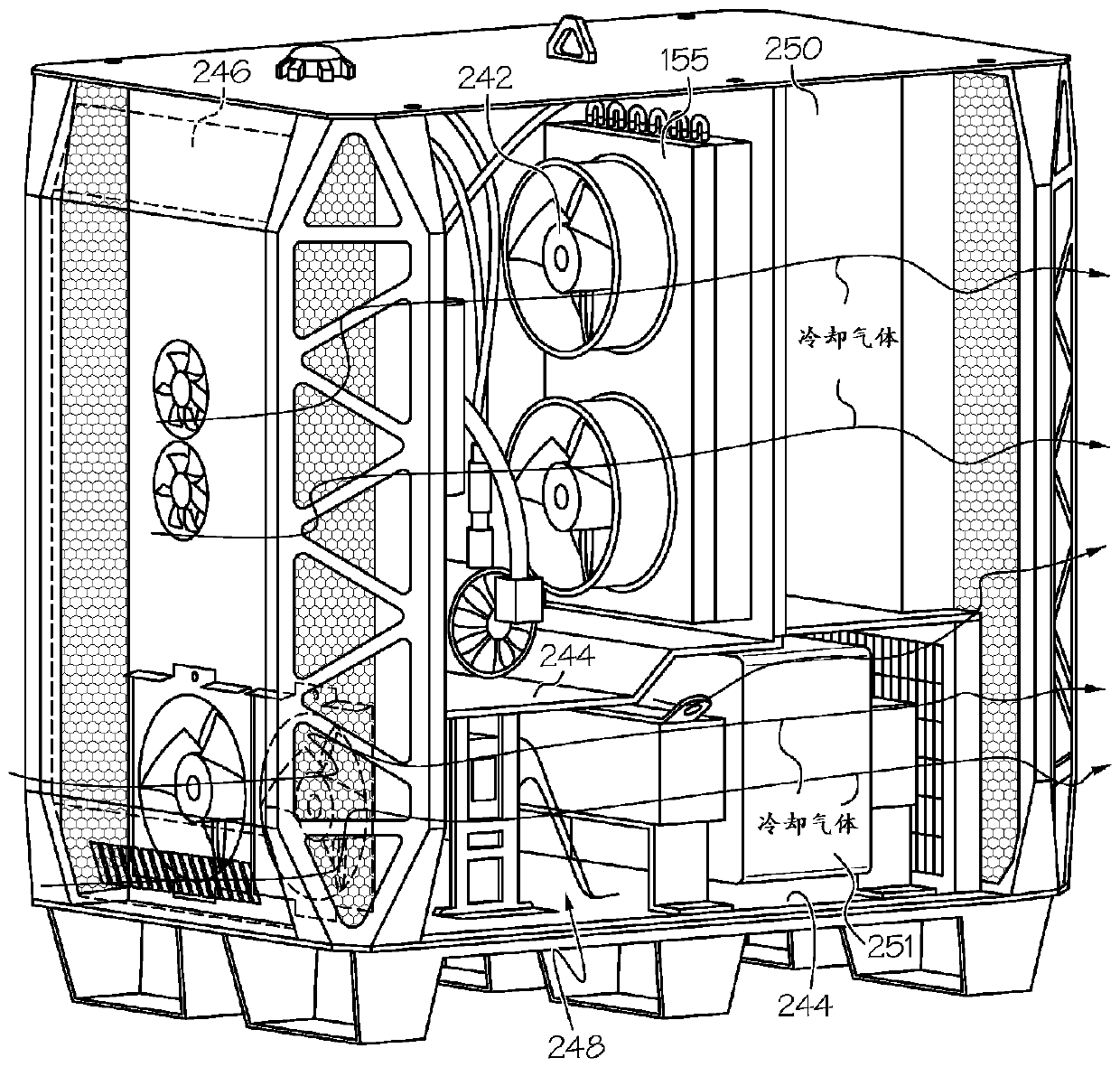

[0030] For example, refer to figure 1 A power supply 100 for a plasma cutting system (eg, a liquid cooled or robotic plasma cutting system) may be configured to support the generation of a plasma arc through a torch tip connected to the power supply by a torch lead. The power supply 100 may include a set of electrical components 150 for plasma arc generation and a power supply housing 200 housing the set of electrical components 150 . Power supply 100 may include a liquid coolant system disposed within housing 200 (in image 3 Shown in cross-sectional view as system 155), the liquid cool...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com