Disc shaped variable vortex throttle piston for automobile engine, internal combustion engine

A technology of automobile engine and internal combustion engine, which is applied in engine control, machine/engine, mechanical equipment, etc. It can solve the problems of incomplete combustion of fuel, slow air flow rate, uneven intake air, etc., and achieve complete combustion, small resistance, and air intake uniform effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

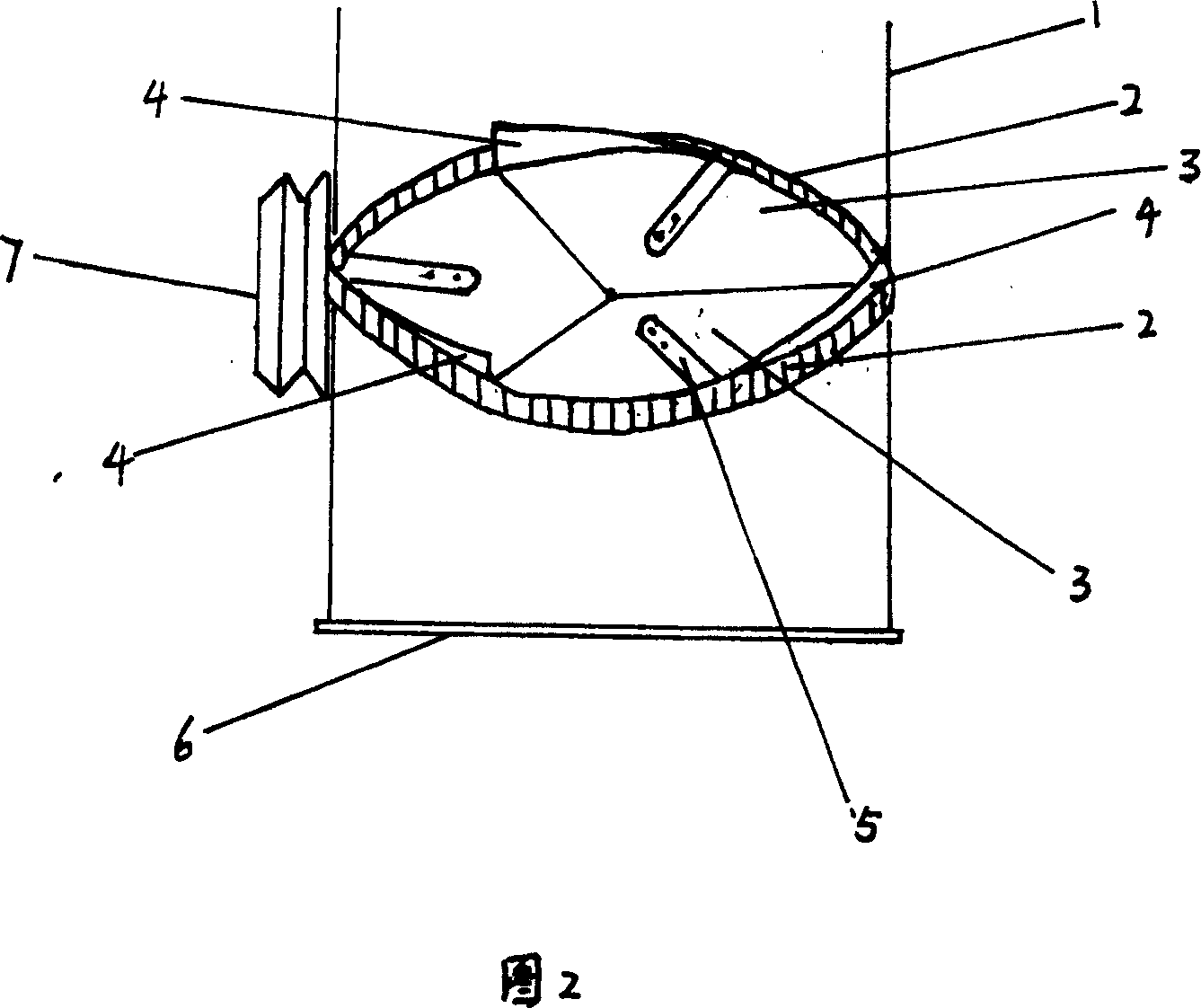

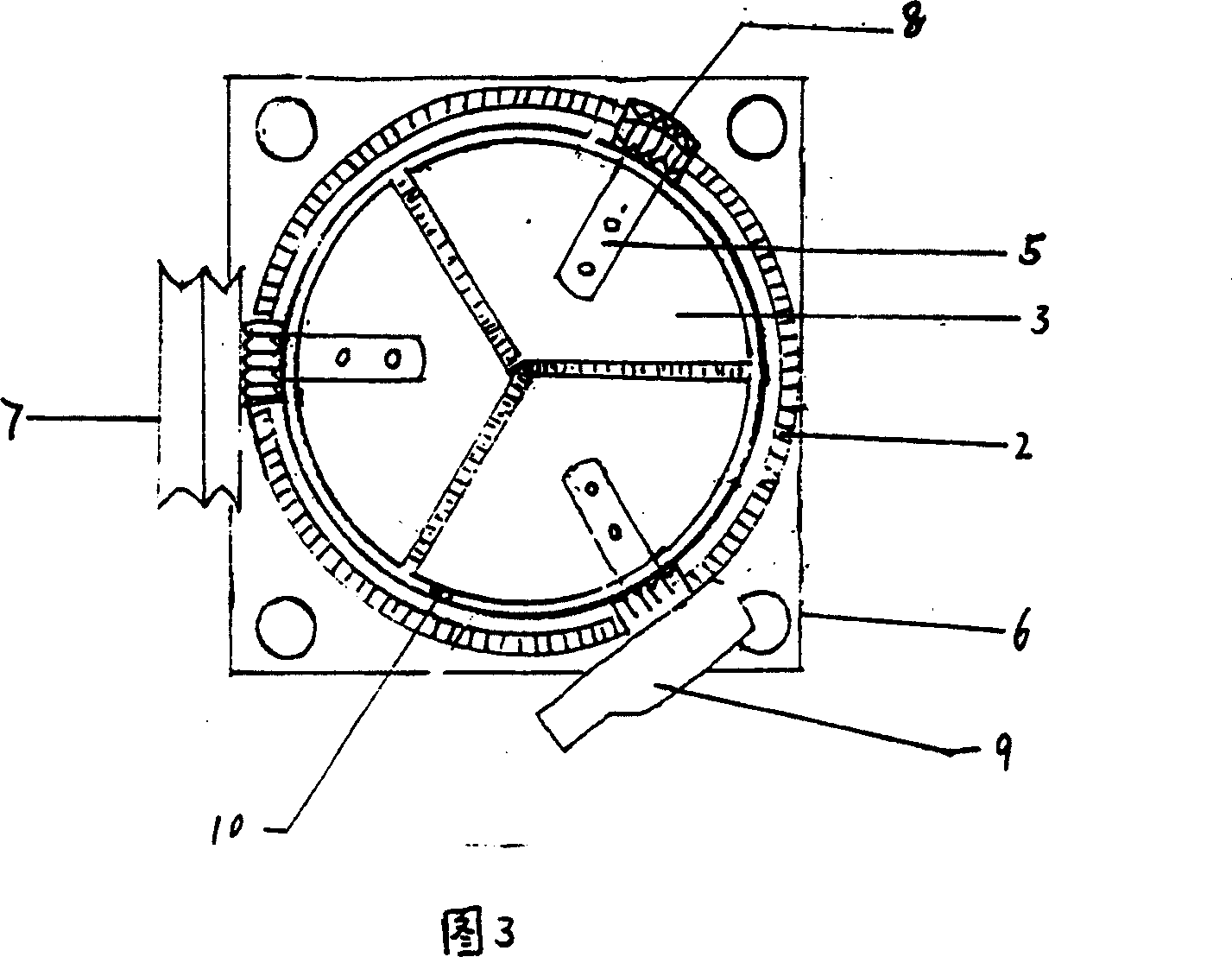

[0014] The disc-shaped automobile engine described in this embodiment, the variable vortex throttle valve of internal combustion engine, its disc has an outer ring gear 2, and this outer ring gear 2 is connected with intake pipe 1, and the disc is evenly divided into three For the same fan-shaped throttle valve 3, guide vanes 4 are designed on the downwardly rotating side of each throttle door, and the guide vanes are perpendicular to the throttle valve. Each fan-shaped throttle valve 3 is fixed on the throttle valve shaft 5, and the outer ring gear On ring 2, there is a throttle shaft gear 8 at the position corresponding to the throttle shaft. The throttle shaft 5 is fixedly connected to the throttle shaft gear 8, and one of the throttle shaft gears is fixedly connected to the throttle drive disc 7. The outer ring The ring gear 2 meshes with the throttle shaft gear 8. When the throttle valve needs to be opened, the throttle driving disc 7 drives the outer ring gear 2 to move ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com