Garbage combustion furnace high in combustion efficiency

A waste burning and combustion efficiency technology, applied in the direction of combustion methods, combustion types, incinerators, etc., can solve air pollution and other problems, and achieve the effects of improving combustion efficiency, ensuring treatment temperature, and uniform combustion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

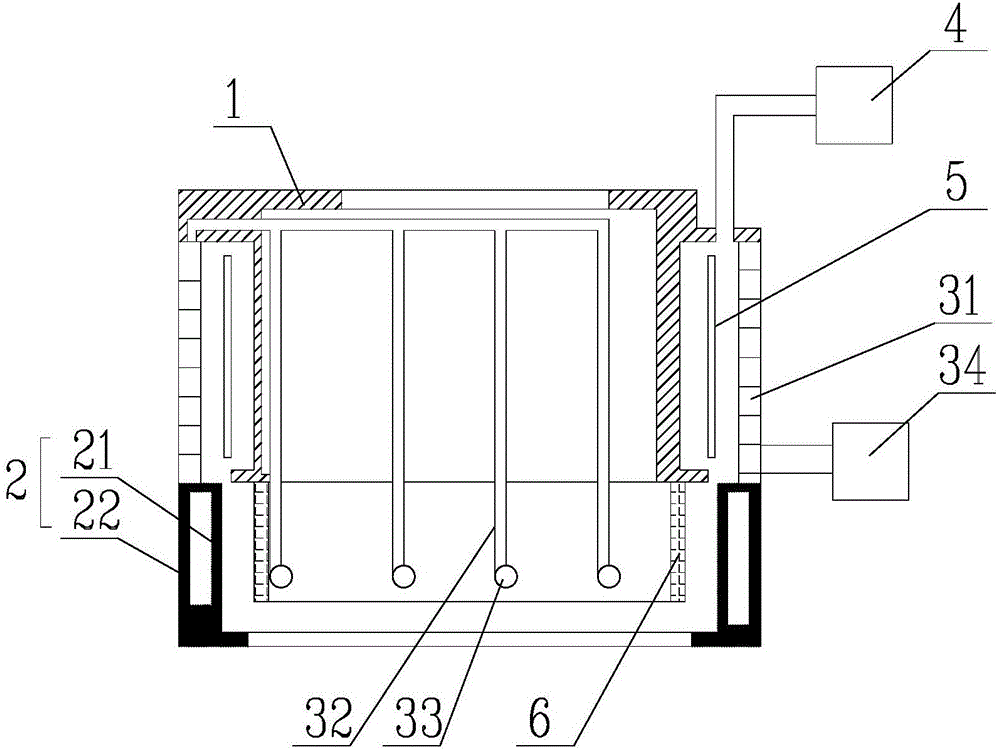

[0016] Such as figure 1 as shown, figure 1 It is a structural schematic diagram of a garbage incinerator with high combustion efficiency proposed by the present invention.

[0017] refer to figure 1 , a garbage incineration furnace with high combustion efficiency proposed by the present invention has a furnace cavity for burning garbage inside, the top of the furnace cavity is provided with a garbage inlet and the bottom is provided with a slagging outlet, and it is characterized in that it includes: an upper furnace Body 1, lower furnace body 2, air intake device, tail gas treatment device 4;

[0018] The outer periphery of the furnace wall of the upper furnace body 1 is provided with a peripheral wall, and a first cooling cavity is formed between the peripheral wall and the furnace wall of the upper furnace body 1. The first cooling cavity is provided with a first air inlet and a first gas outlet, and the exhaust gas The processing device 4 communicates with the first air...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com