Heating stove

A heating stove and shell technology, applied in the field of heating stoves, can solve the problems of fuel obstruction, intelligent control, adjustment, high noise, etc., and achieve the effects of reducing power consumption, improving user comfort, and improving combustion efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

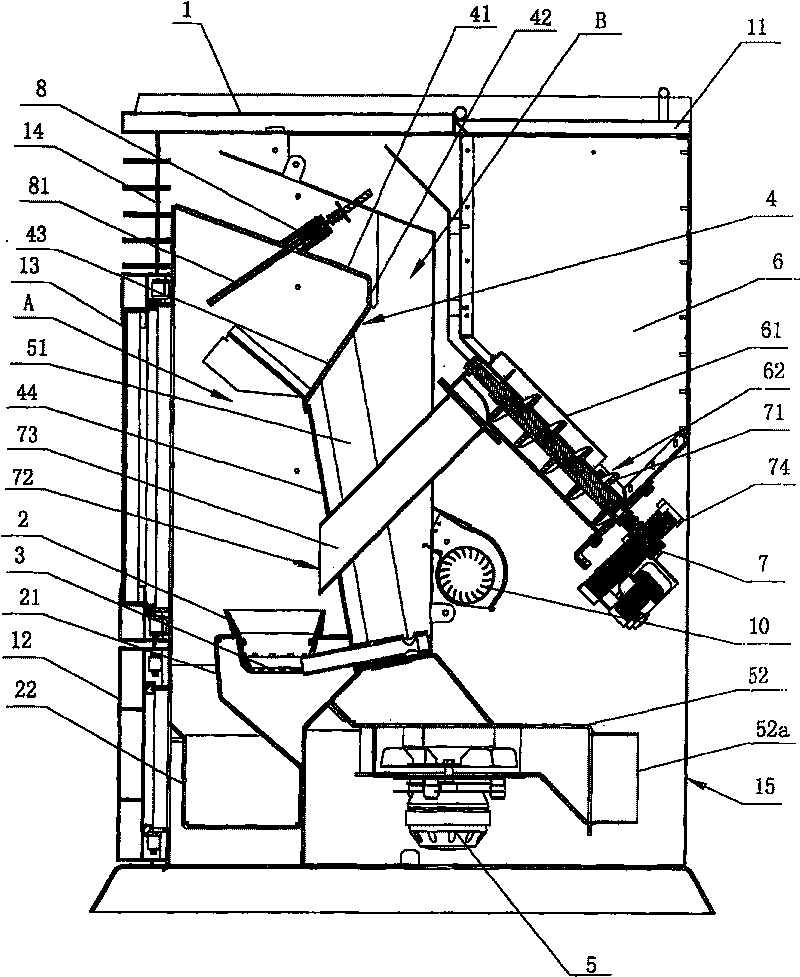

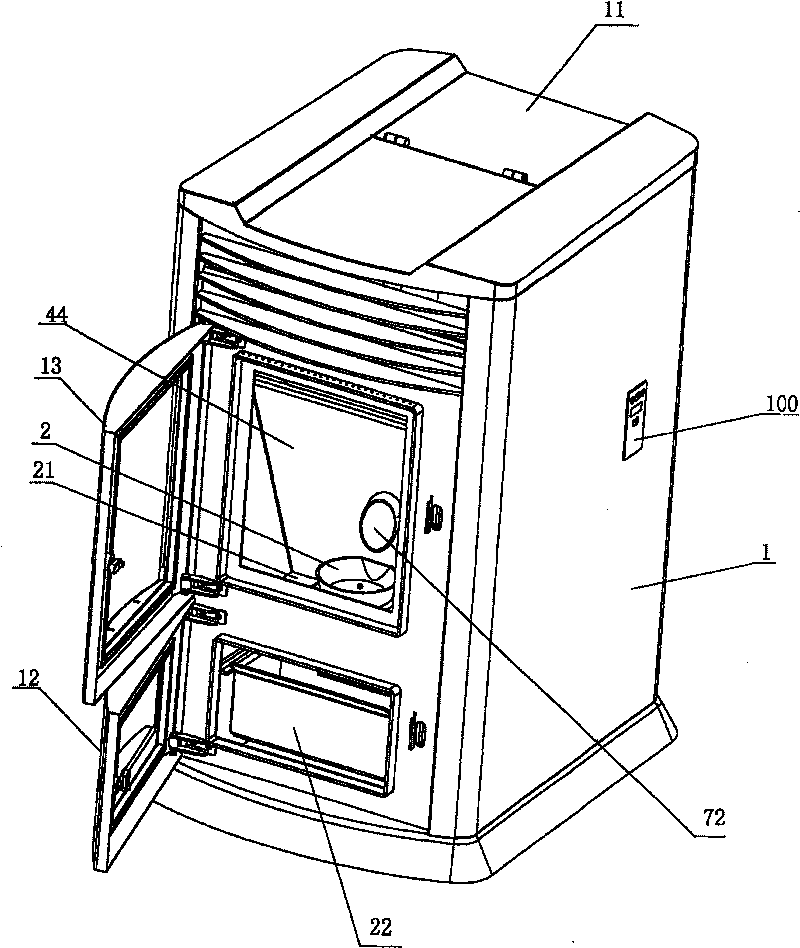

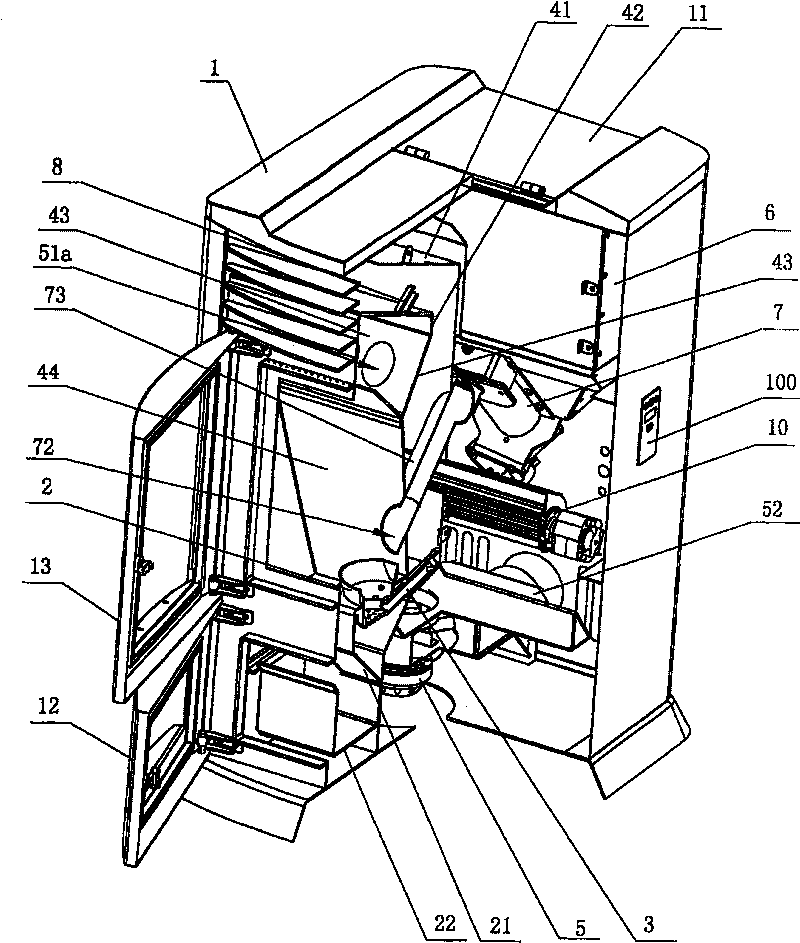

[0035] Such as Figure 1 to Figure 5 As shown, the heating furnace includes a housing 1 and the following components arranged in the housing 1:

[0036] A fuel box 2 arranged under the front part in the internal space of the casing 1, the fuel box 2 is limited by a base 21 with a limit hole;

[0037]A heating device 3 arranged at the bottom of the fuel cartridge 2, in this embodiment, the heating device 3 adopts a thermal resistance heating rod;

[0038] An ash hopper 22 arranged under the fuel box 2;

[0039] A partition plate 4 arranged on the top and rear side of the fuel box 2, the partition plate 4 divides the space above the fuel box 2 into a furnace A, the partition plate 4 includes a top-to-bottom connected bottom inclined The first part 41, the third part 43 whose bottom is inclined to the front side, the fourth part 44 whose botto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com