Intelligent oil tank cap and oil tank

A fuel tank cap, an intelligent technology, applied in the substructure, the layout combined with the fuel supply of the internal combustion engine, the power plant, etc., can solve the problems of uneven distribution of gasoline components, affecting gasoline combustion efficiency, affecting the power effect of automobiles, etc., to achieve practical The effect of improving the application effect, increasing the stirring range, and improving the uniform distribution effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

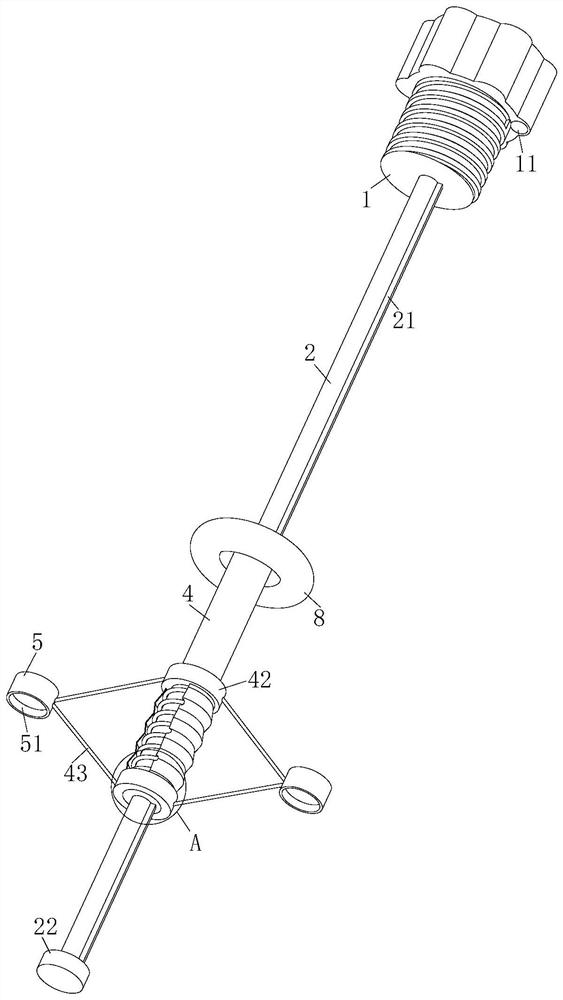

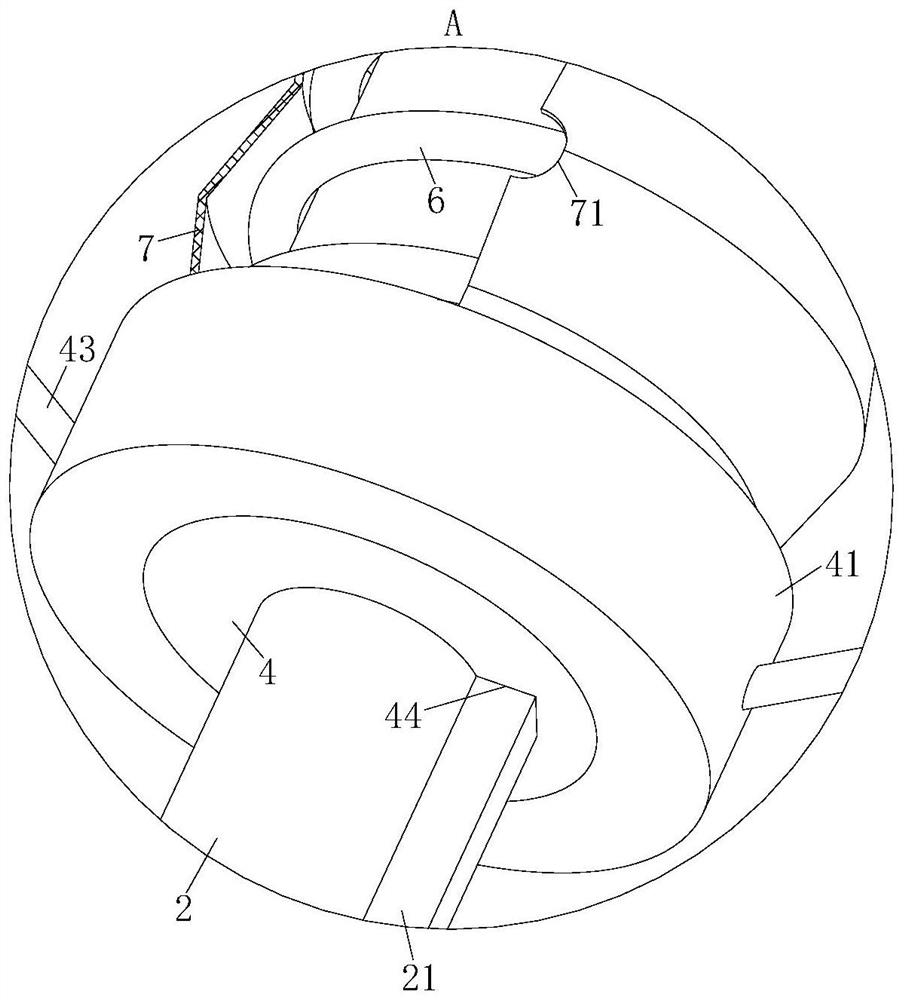

[0032] As an embodiment of the present invention, the No. 2 ring block 42 is slidingly connected to the outer wall of the ring sleeve 4, and a spring 6 is arranged between the No. 2 ring block 42 and the No. 1 ring block 41; the spring 6 is sleeved on On the outer wall of the ring sleeve 4, one end of the spring 6 is connected to the No. 1 annular block 41, and the other end is connected to the No. 2 annular block 42; during operation, the centrifugal force generated by the rotation of the agitating disc 5 driven by the wire rope 43 is driven by reducing the speed of the motor 3. After being less than the elastic force of the spring 6, the spring 6 will drive the No. 2 ring block 42 away from the No. 1 ring block 41. When the No. 2 ring block 42 moves, it will drive the stirring plate 5 to move close to the cover body 1 through the wire rope 43, so that the stirring plate 5 It also moves while rotating around the rotating rod 2, thereby increasing the stirring range of the stir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com