Patents

Literature

31results about How to "Guaranteed processing temperature" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

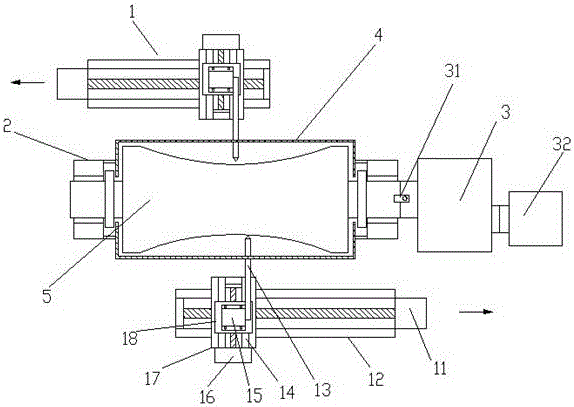

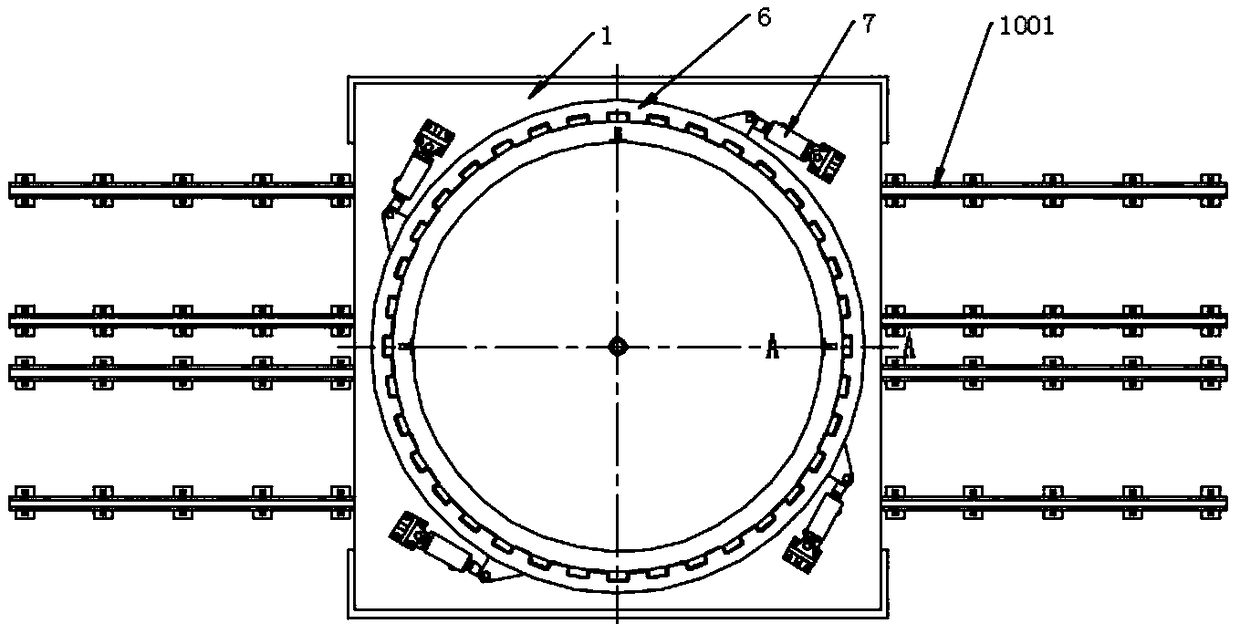

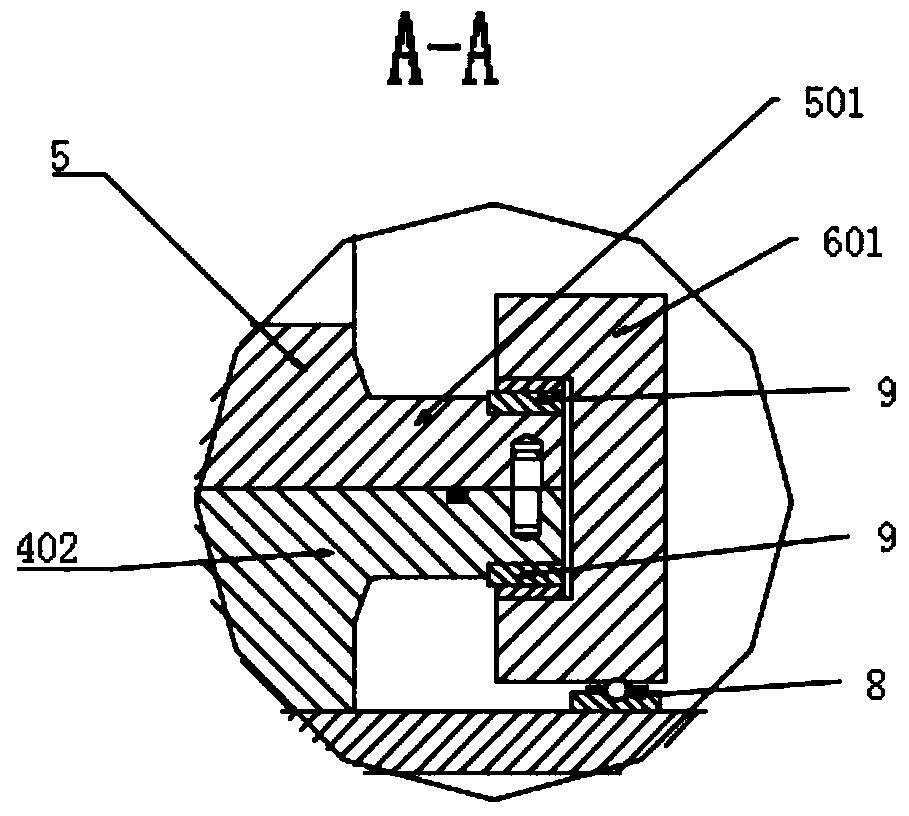

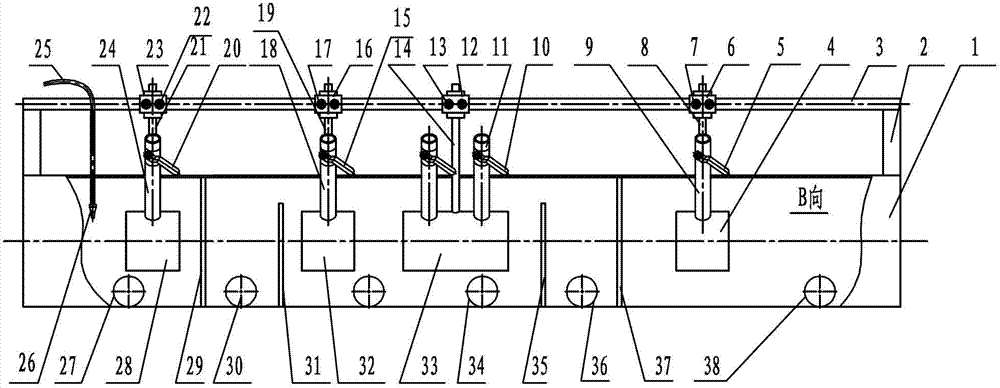

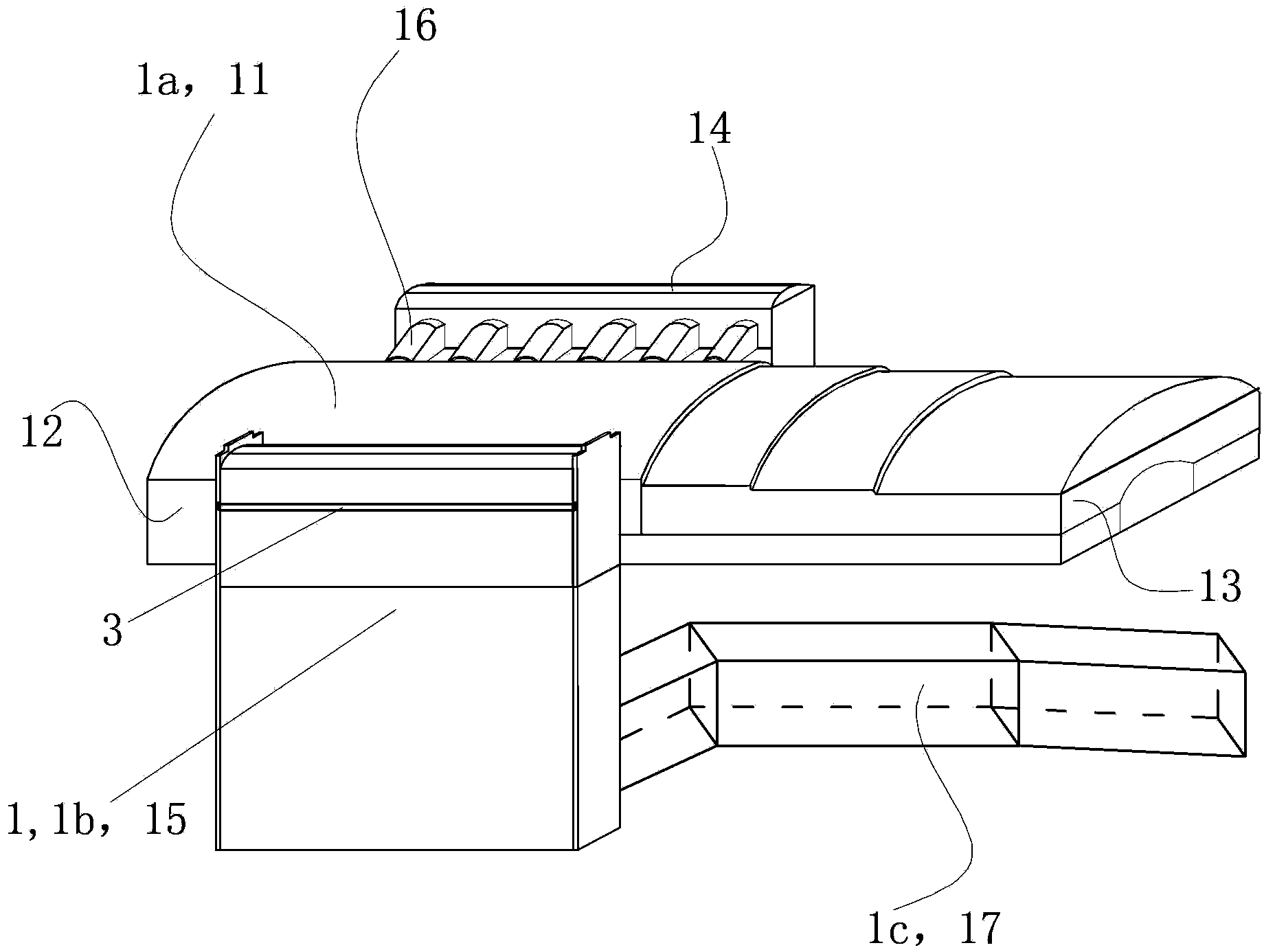

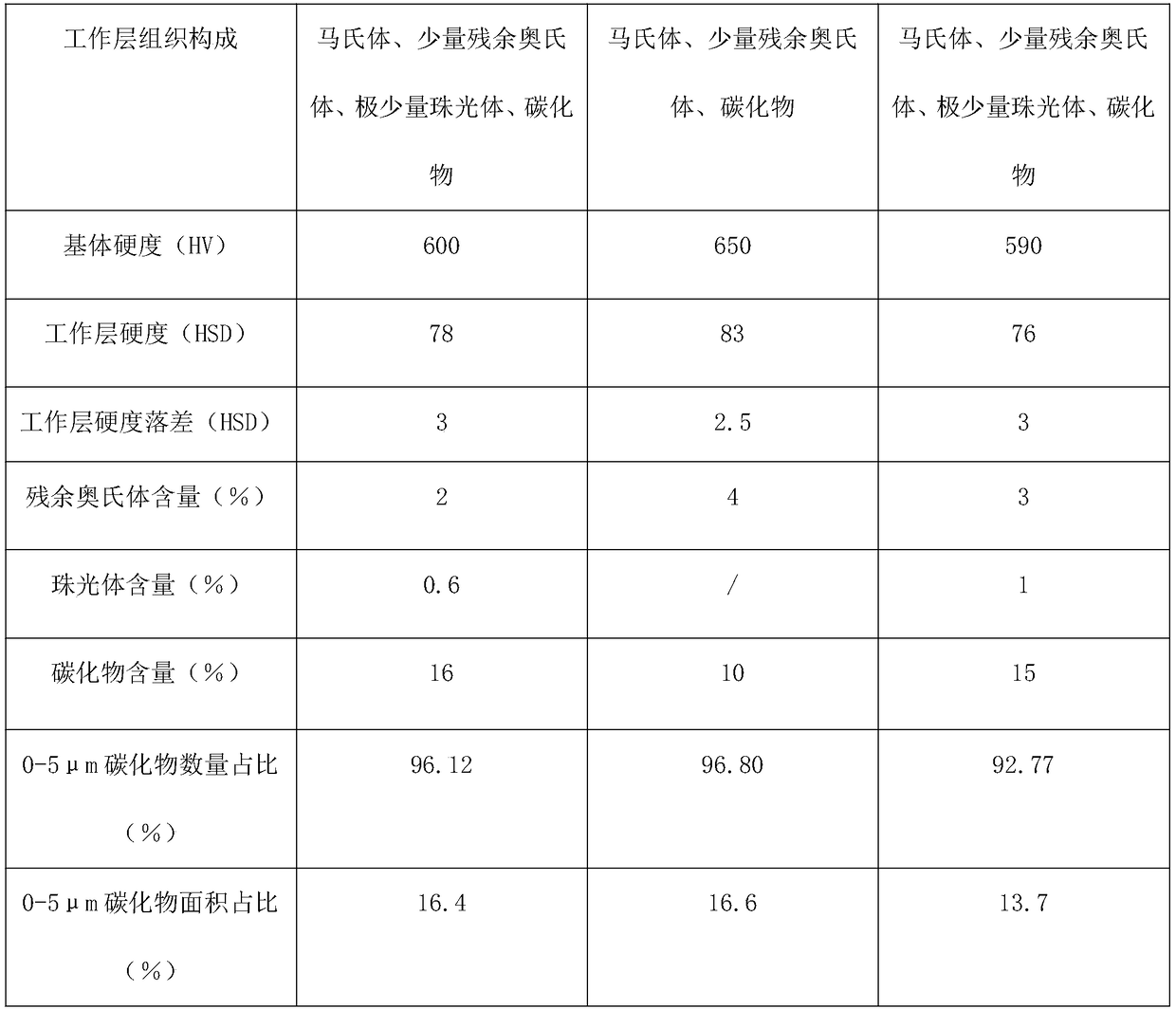

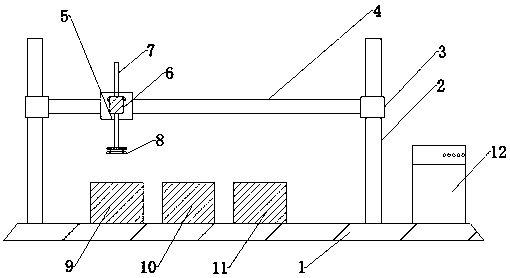

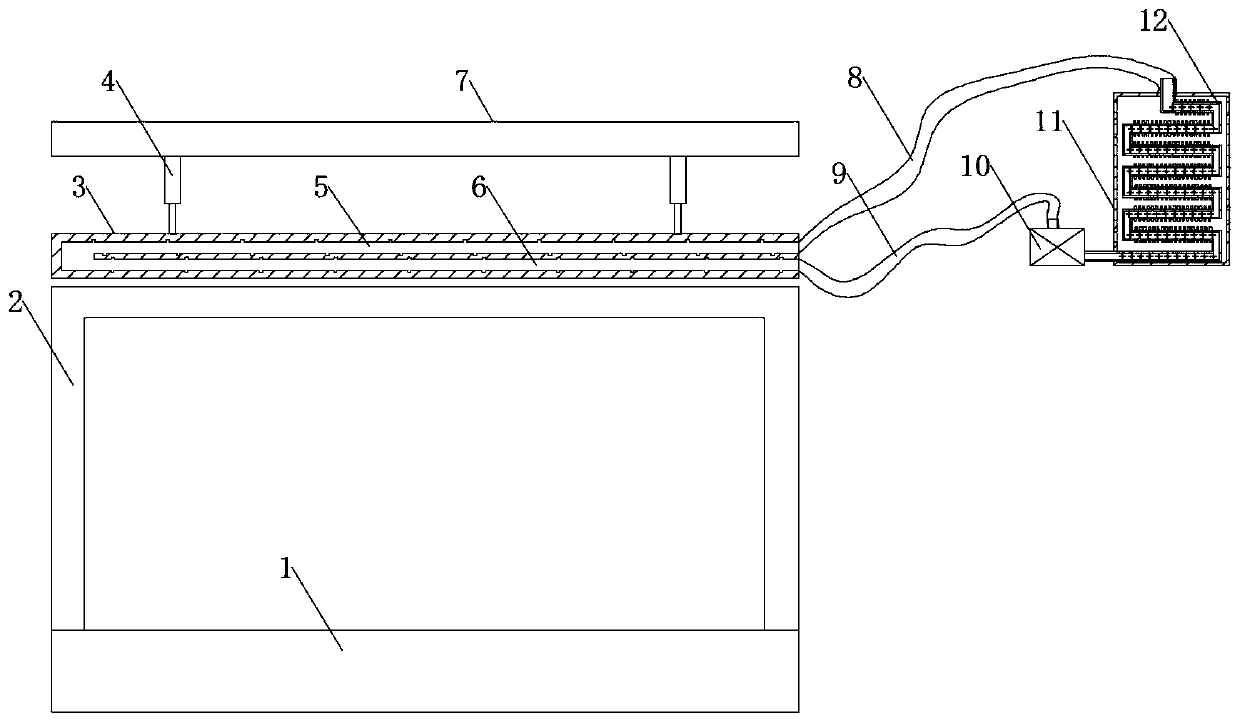

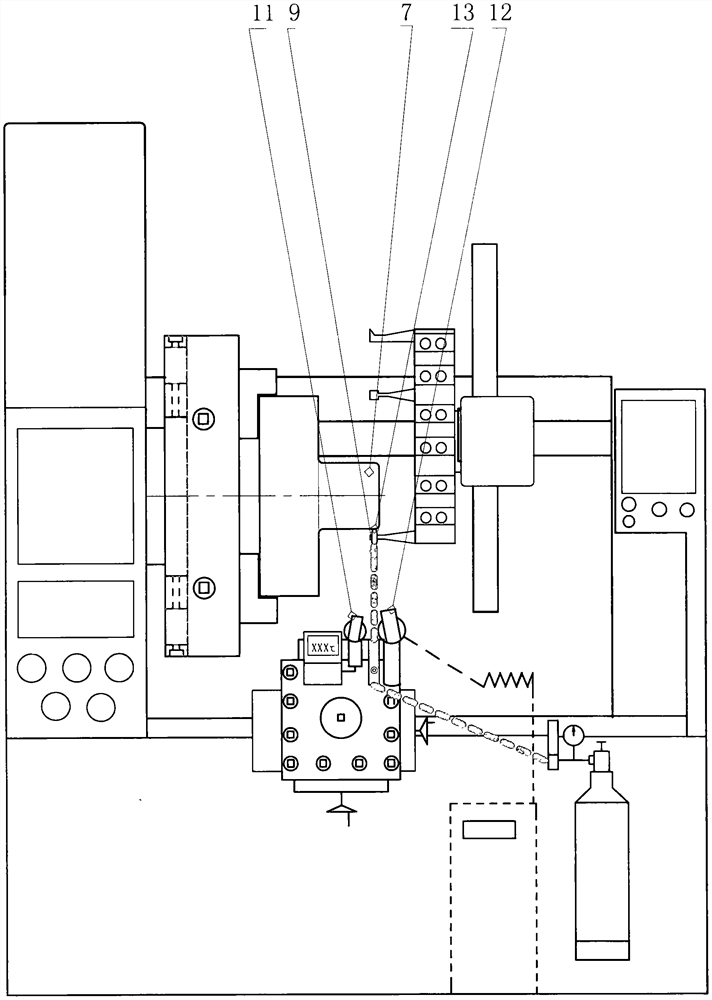

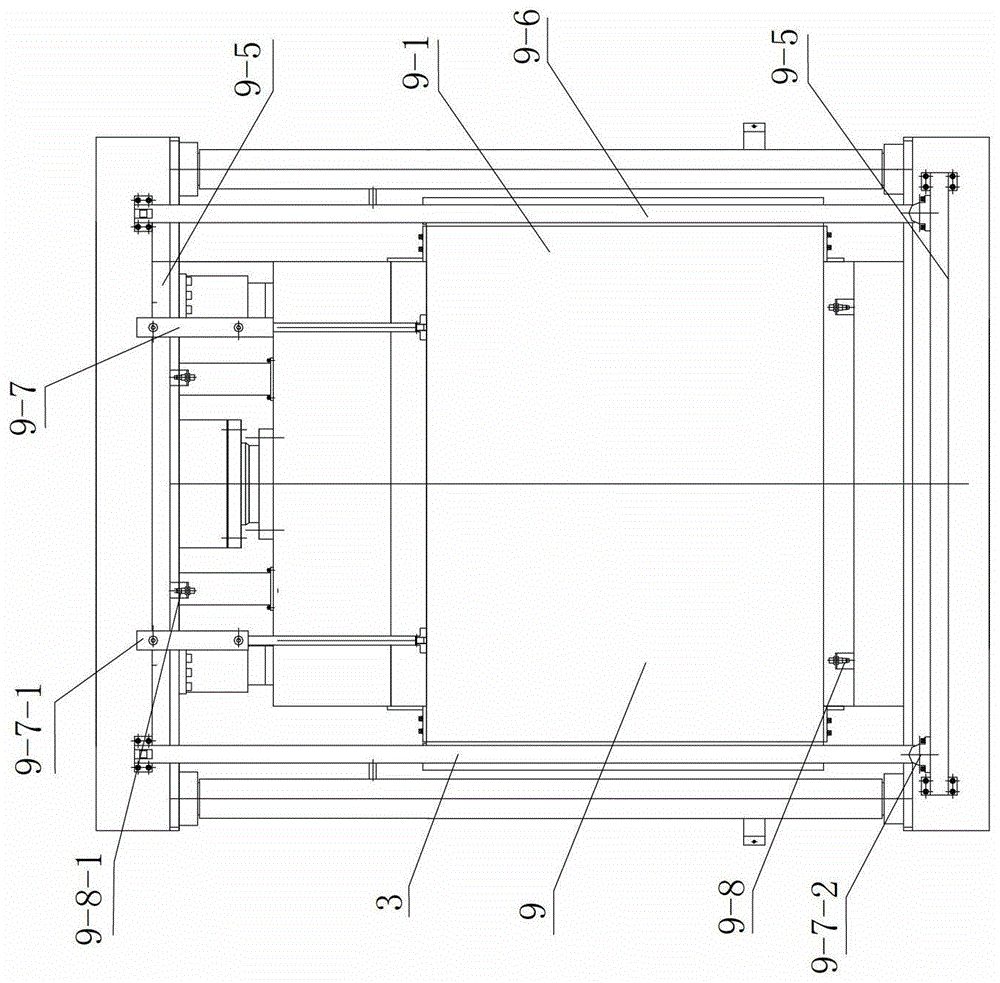

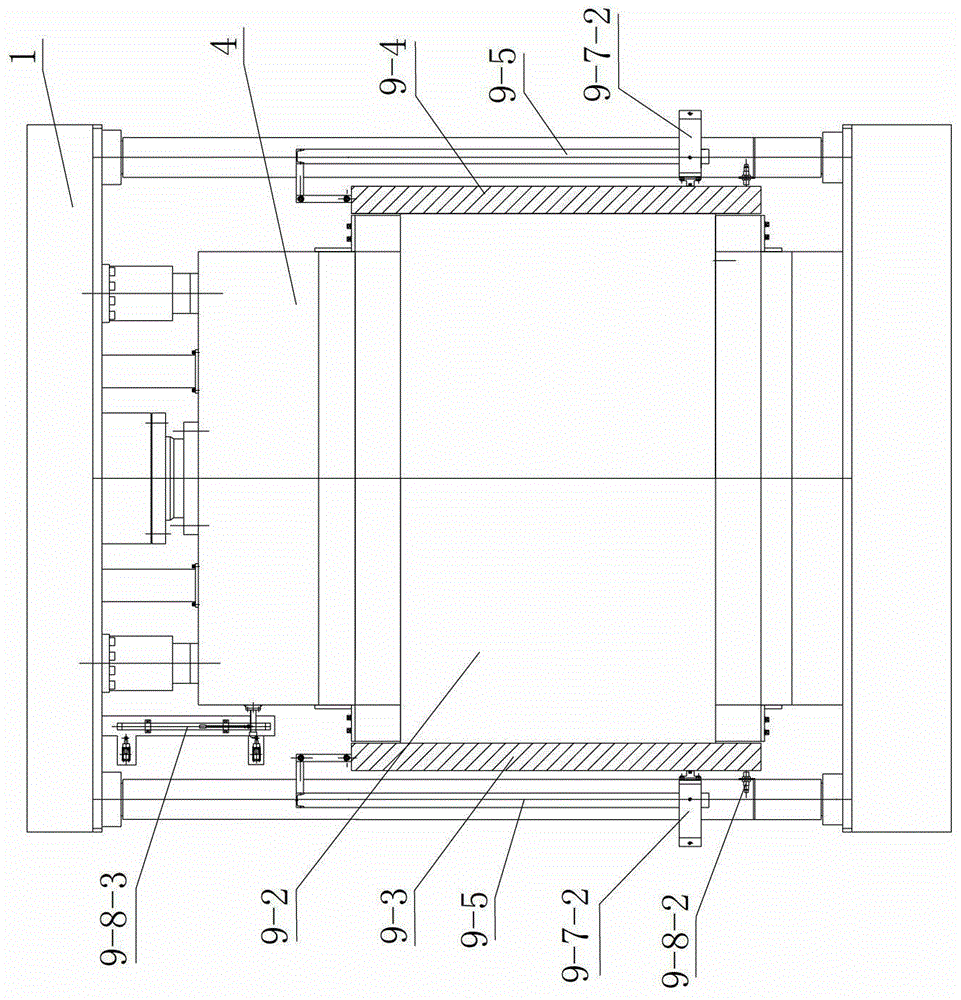

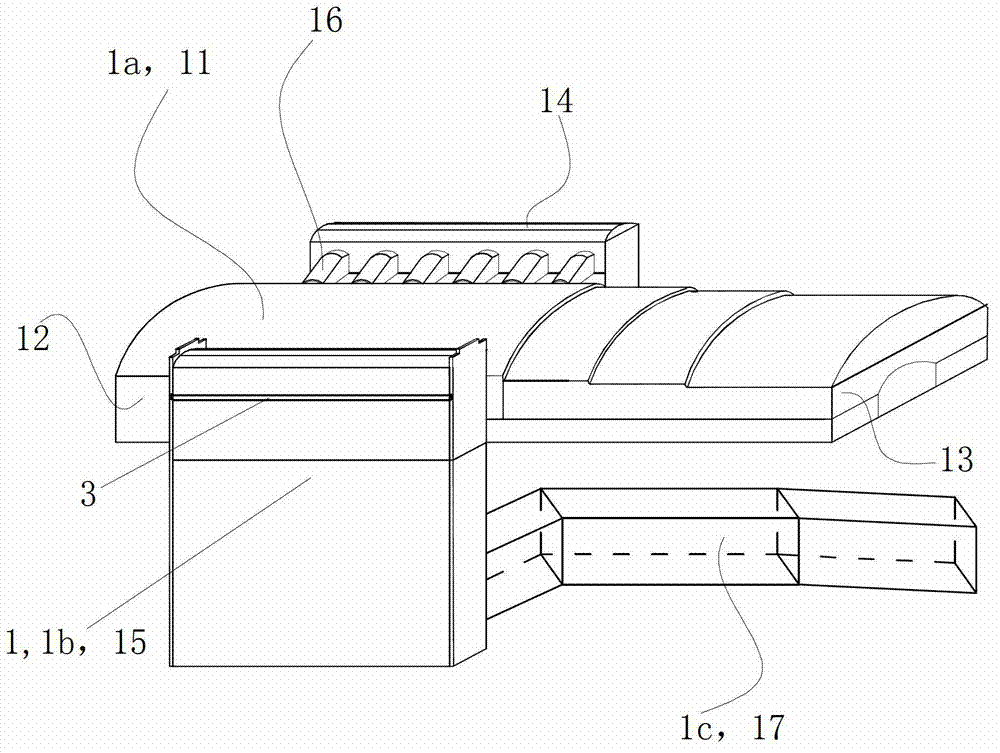

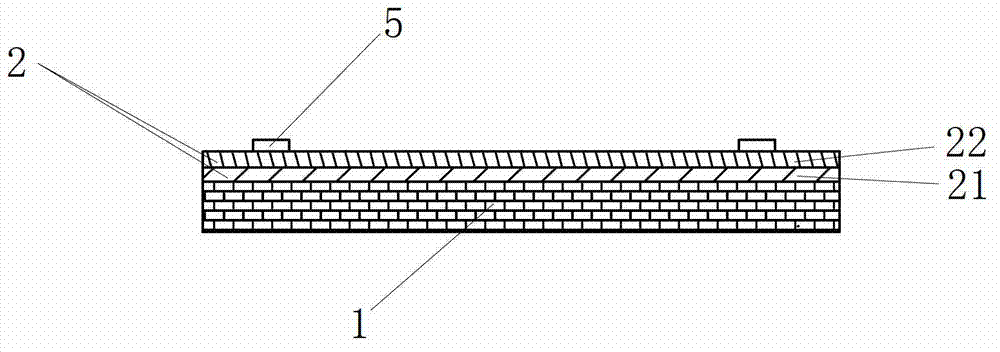

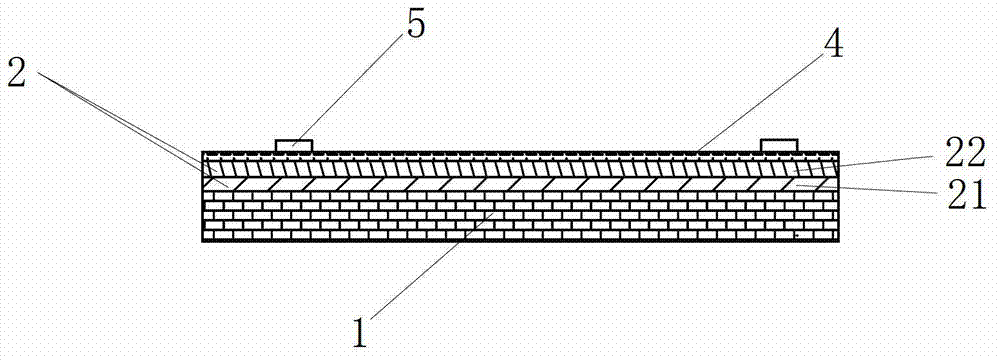

Roll surfacing repair device and repair method

ActiveCN105798424AImprove work efficiencyDoes not affect workArc welding apparatusThermal insulationEnergy consumption

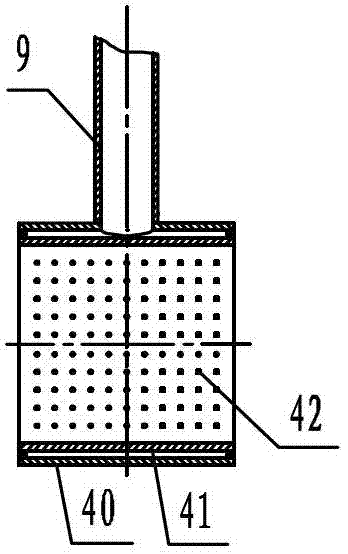

The invention discloses a roll surfacing repair device and a repair method. The roll surfacing repair device comprises two bearing bases and two groups of surfacing assemblies, wherein each of the two groups of surfacing assemblies comprises a transverse guide rail, a longitudinal guide rail and a welding machine; first bearing plates are separately arranged on the transverse guide rails; the longitudinal guide rails are separately arranged on the first bearing plates; second bearing plates are arranged on the longitudinal guide rails; the welding machines are arranged on the second bearing plates; a thermal insulation cover is arranged between the two bearing bases; and roll repair is carried out by detecting before surfacing, pre-heating before welding, welding, heat treatment and processing. In this way, the roll surfacing repair device and the repair method adopt the surfacing assemblies to replace part of manual operation, so that risks are reduced; and moreover, the thermal insulation cover is especially adopted, so that the work of a welding gun is not affected, loss of heat can be reduced, energy consumption is reduced, the technical temperature of roll surfacing is ensured, and the surfacing quality is improved.

Owner:SHAZHOU PROFESSIONAL INST OF TECH

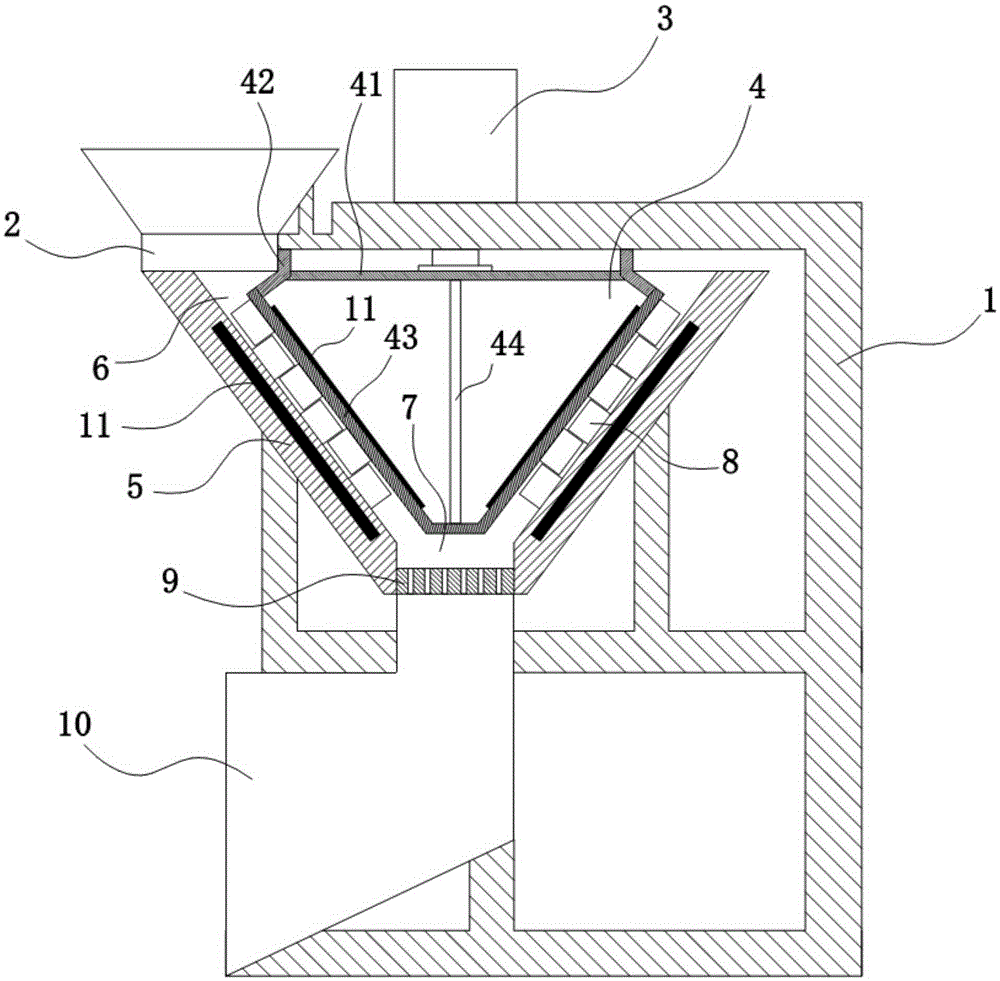

Grinding gear smashing type feed processing machine

The invention relates to a grinding gear smashing type feed processing machine. The grinding gear smashing type feed processing machine comprises a feeding hopper, a discharging hopper, a motor and a smashing and mixing device which are installed on a machine frame, wherein the smashing and mixing device comprises an inner grinding block driven by the motor and an outer grinding barrel installed on the periphery of the inner grinding block and located on the machine frame; the inner grinding block and the outer grinding barrel are of a conical structure; multiple grinding gears which are staggered are arranged on the outer wall of the inner grinding block and the inner wall of the outer grinding barrel; an extrusion space is formed at the conical lower ends of the outer grinding barrel and the inner grinding block; a filtering board fixedly connected to the lower end of the outer grinding barrel is arranged below the extrusion space; the discharging hopper is arranged below the filtering board; an annular feeding groove is formed in the upper ends of the inner grinding block and the outer grinding barrel and communicated with an outlet of the feeding hopper; multiple electric heating pieces arranged at intervals are embedded into the lateral wall of the outer grinding barrel.

Owner:WUXI SHUANGSHI MACHINERY CO LTD

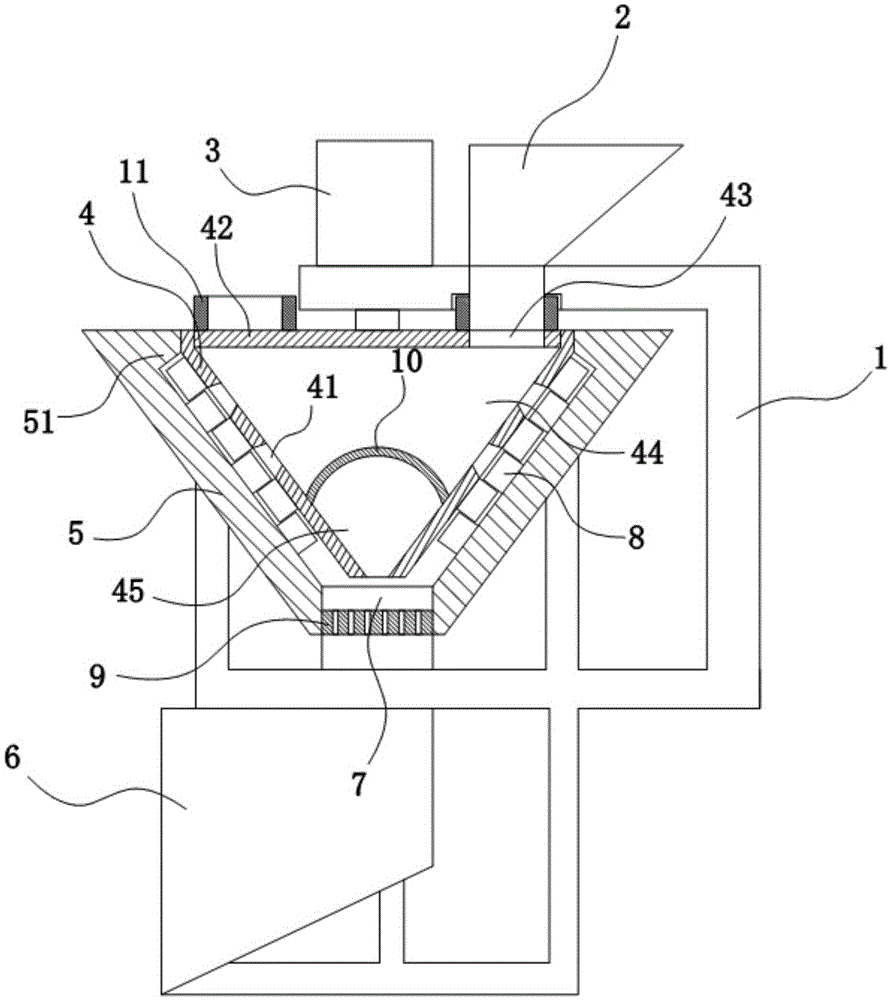

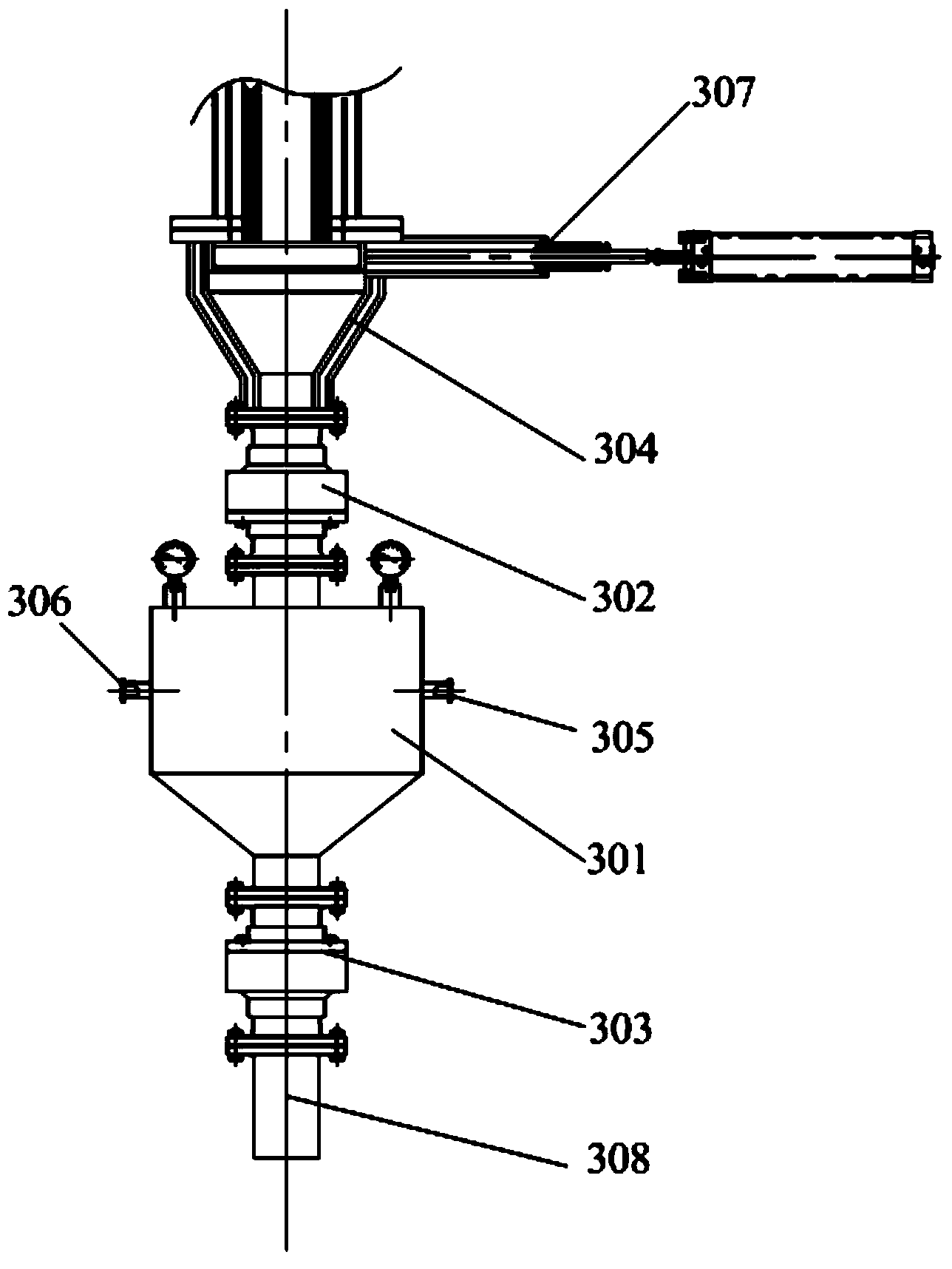

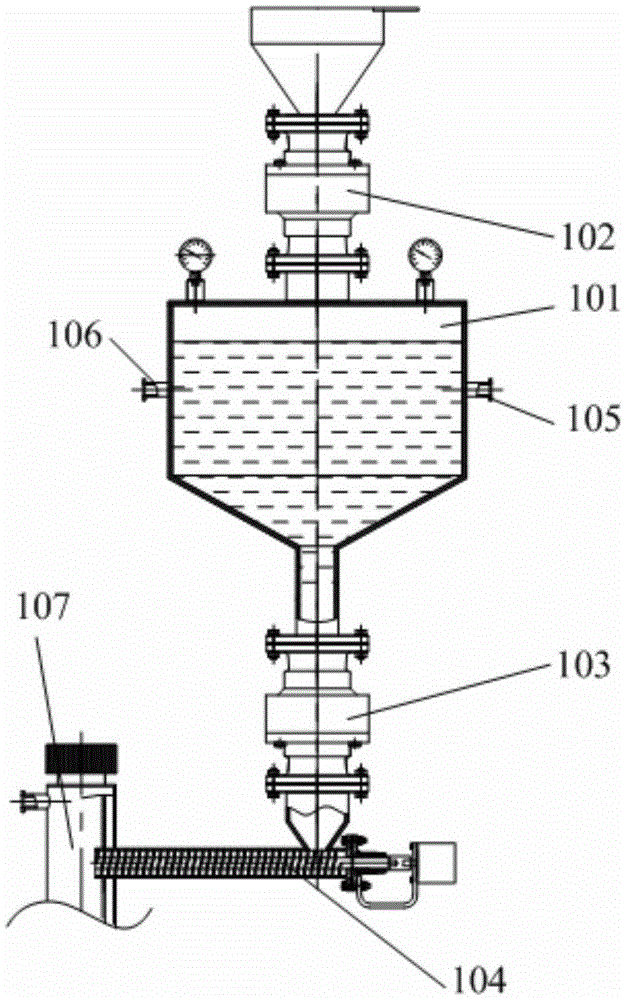

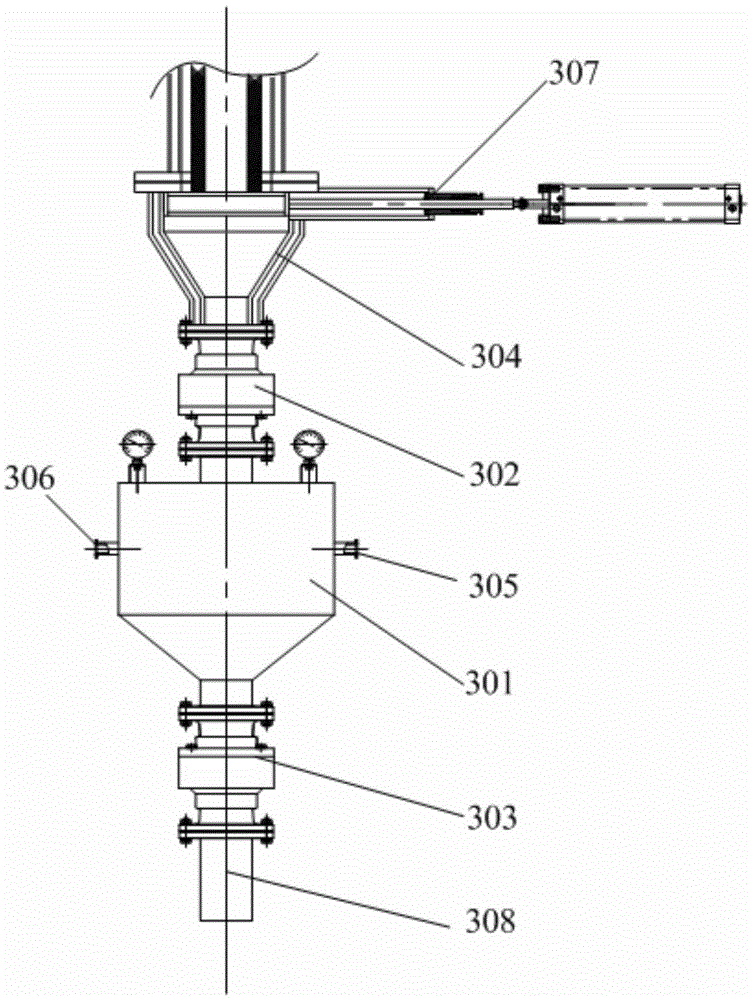

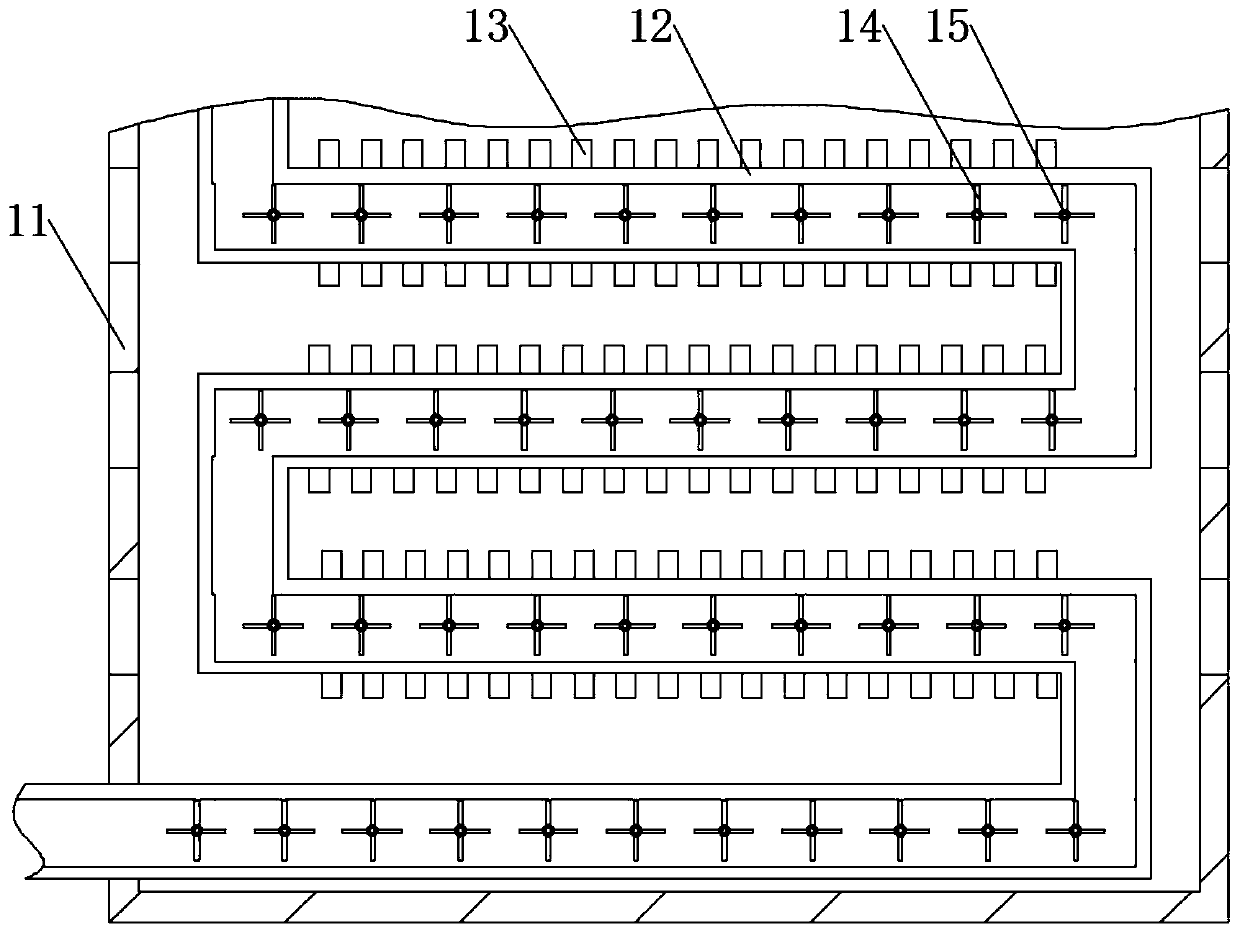

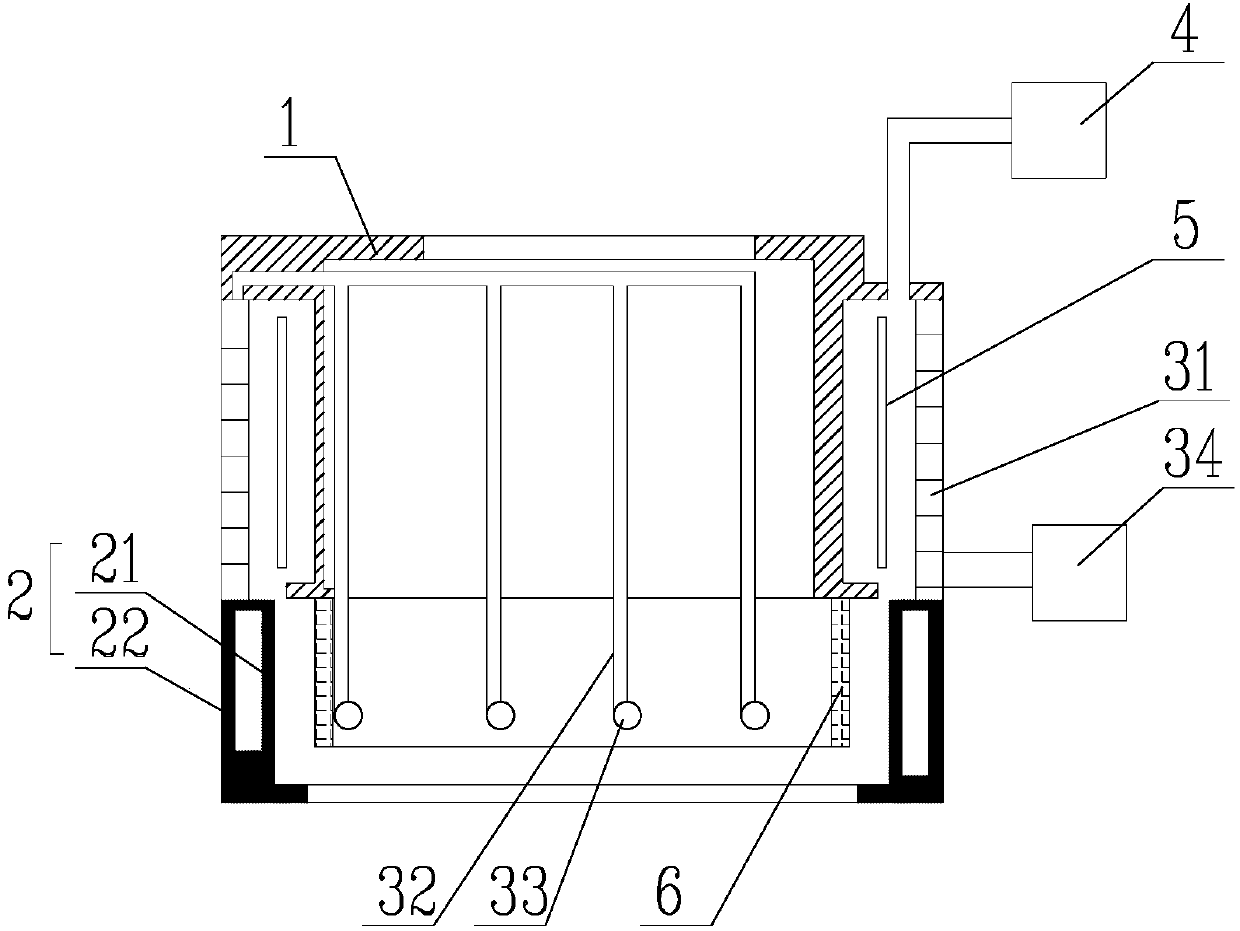

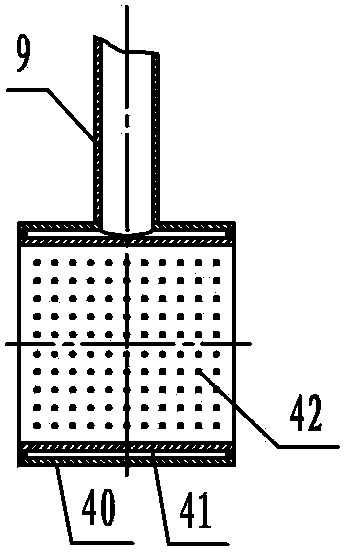

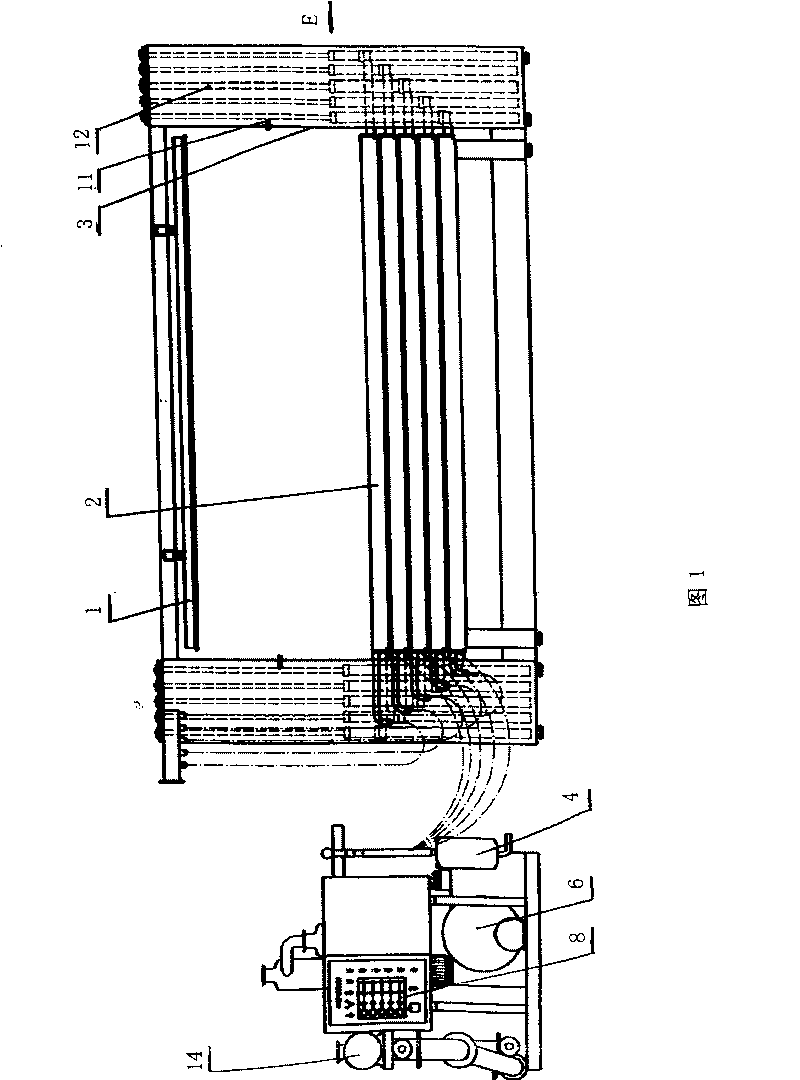

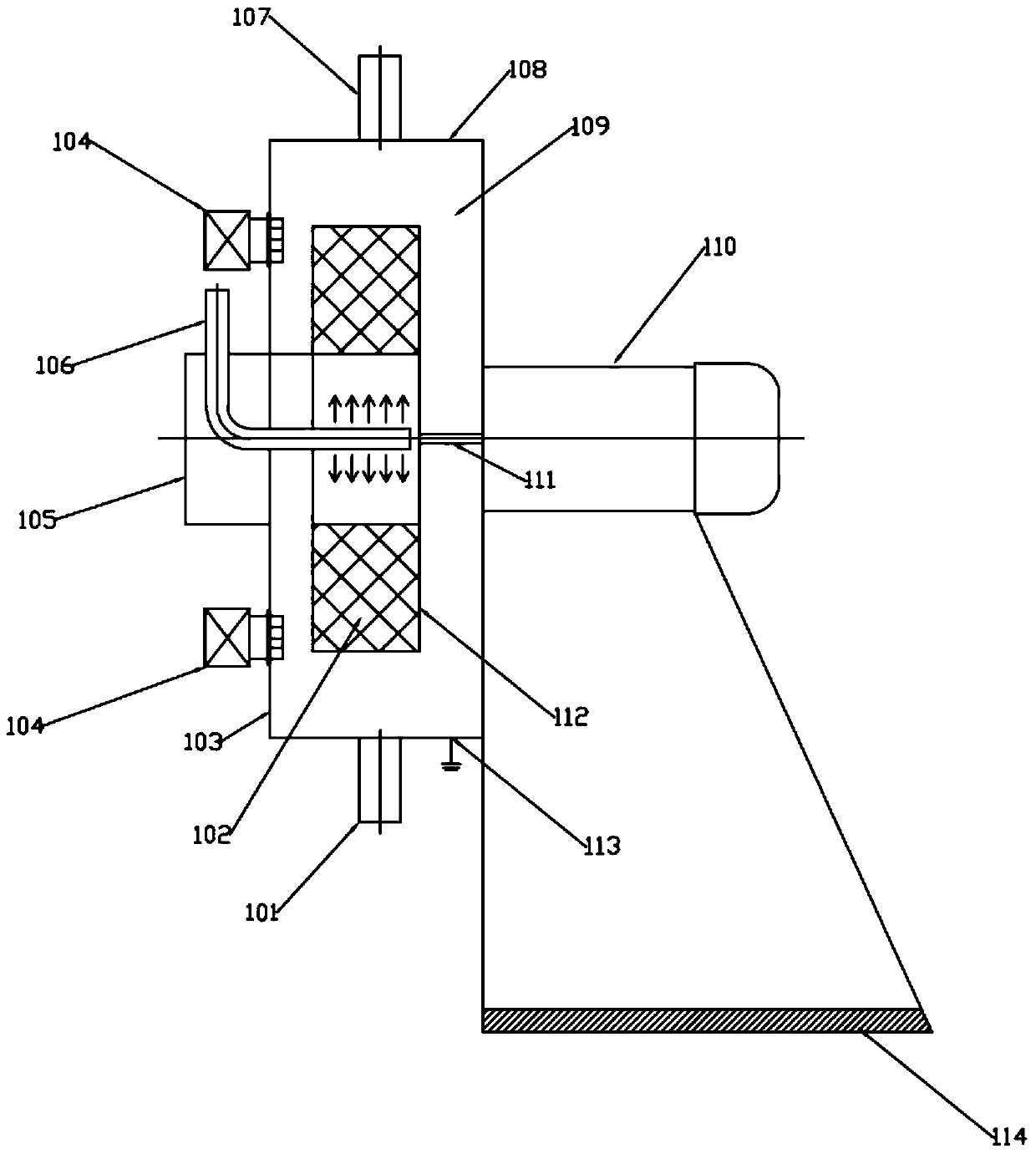

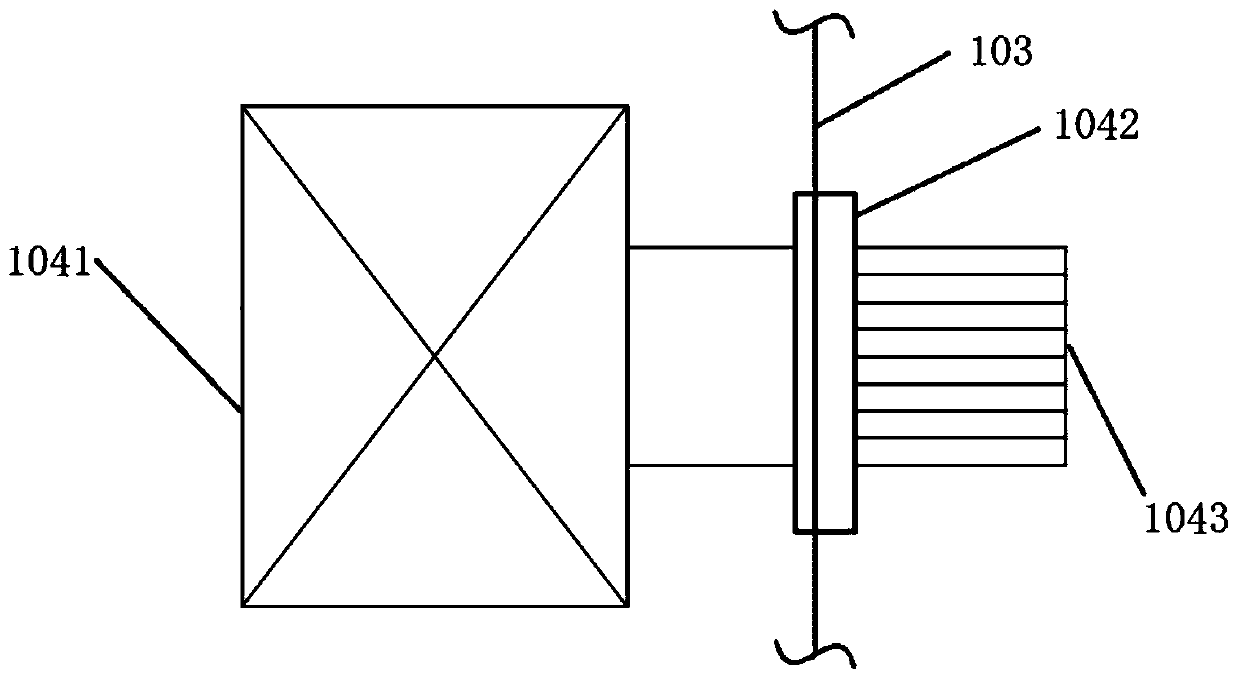

Graphite purifying device

ActiveCN103723719AGuarantee the quality of purificationGuaranteed purification effectCarbon compoundsGraphiteMaterials science

The invention provides a graphite purifying device. The device comprises a feeding system, a purifying furnace and a discharging system which are sequentially arranged in vertical direction, wherein the purifying furnace comprises a muffle for purifying and heating graphite and a resistance heating device surrounding the muffle in circumferential direction. The graphite purifying device works in vertical direction, the feeding system feeds a graphite material at the top of the purifying furnace, the graphite is purified in the purifying furnace and is discharged by the discharging system at the bottom of the purifying furnace, the graphite material is purified in the muffle, and the resistance heating device is used for guaranteeing the processing temperature in the muffle so as to realize heating at high temperature to guarantee the quality of graphite purifying. Due to structural design of the graphite purifying device with the vertical structure, the graphite can be purified continuously at high temperature, so that the production efficiency is improved, and the graphite purifying effect is guaranteed.

Owner:ADVANCED FOR MATERIALS & EQUIP

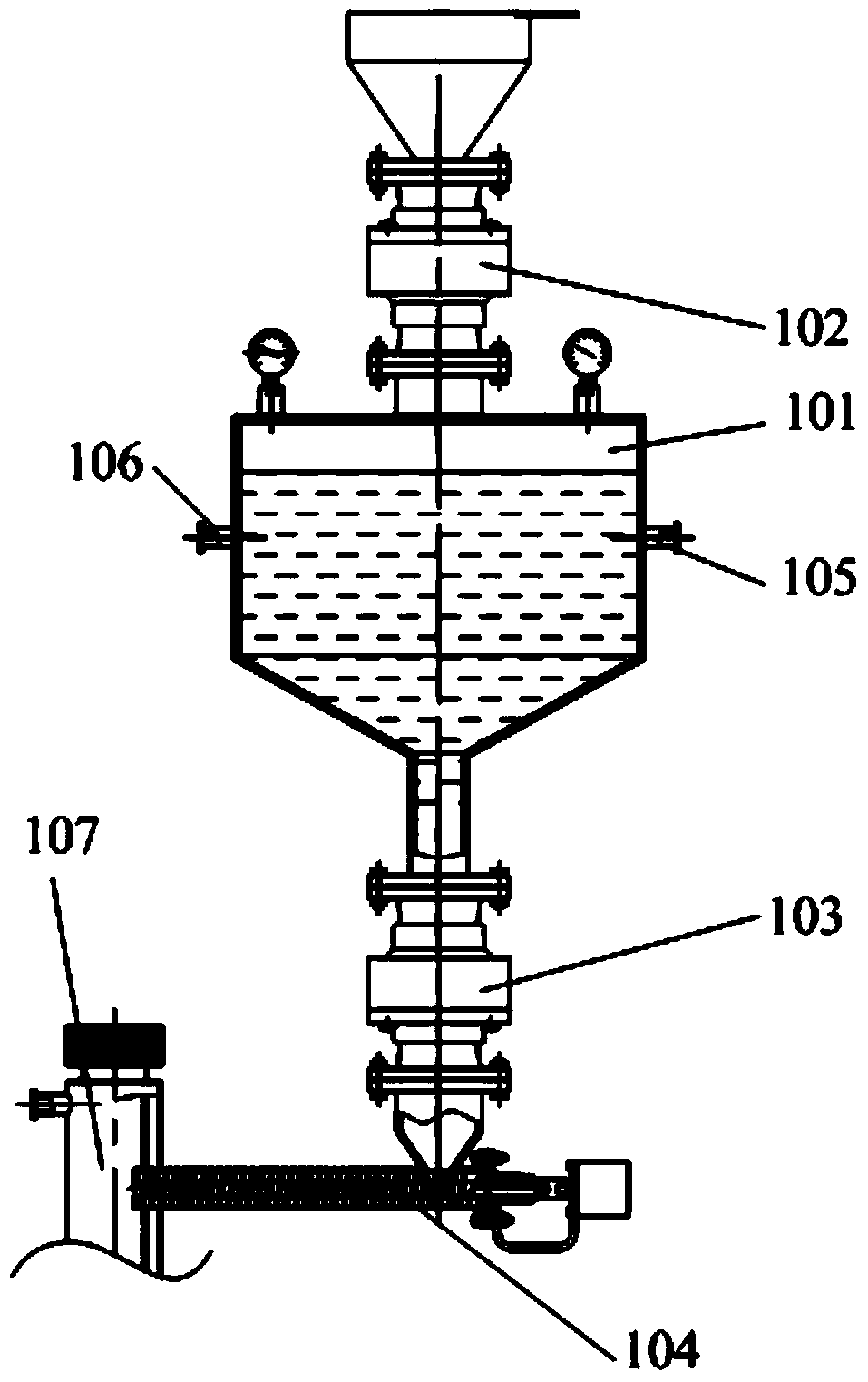

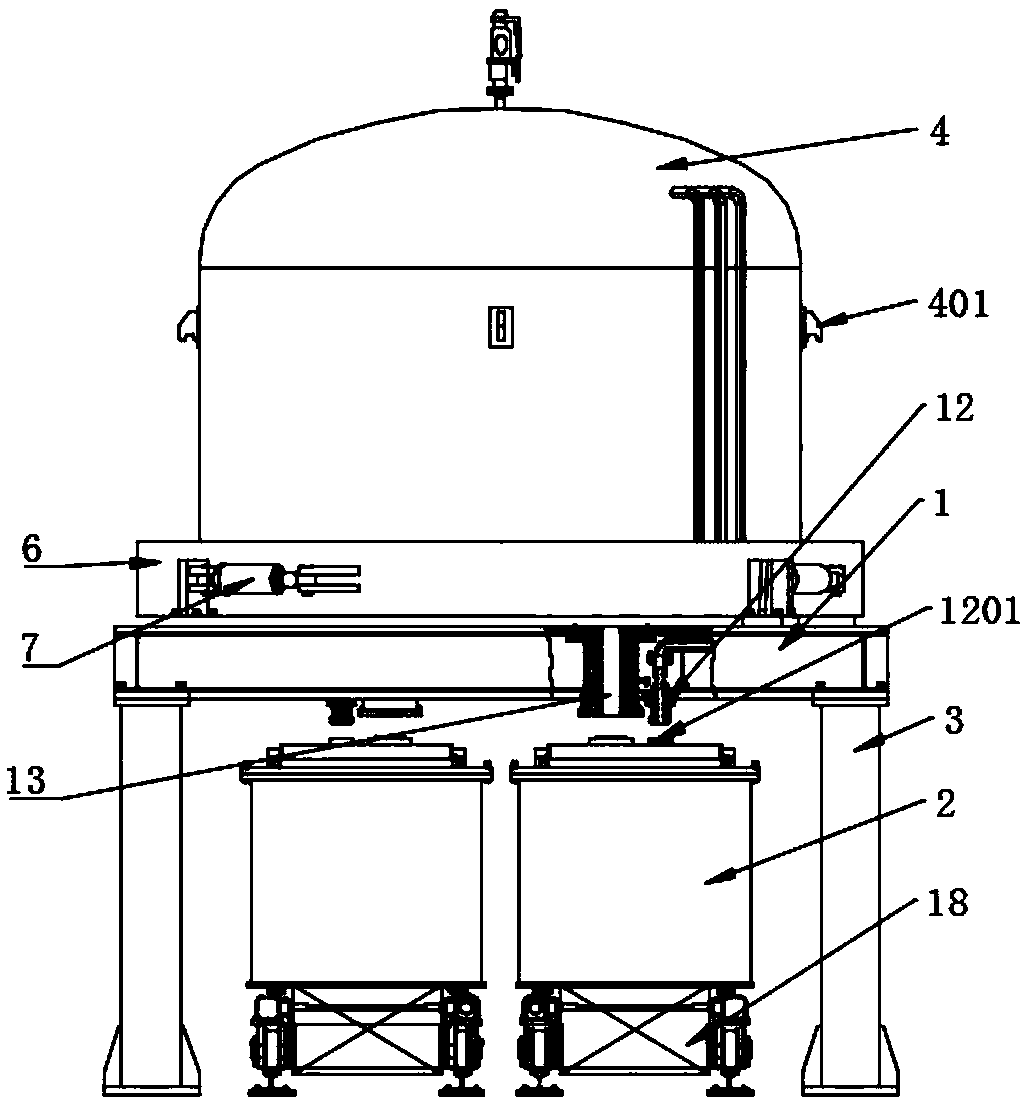

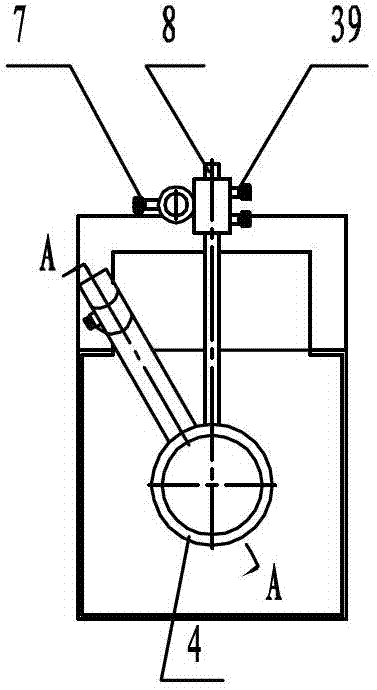

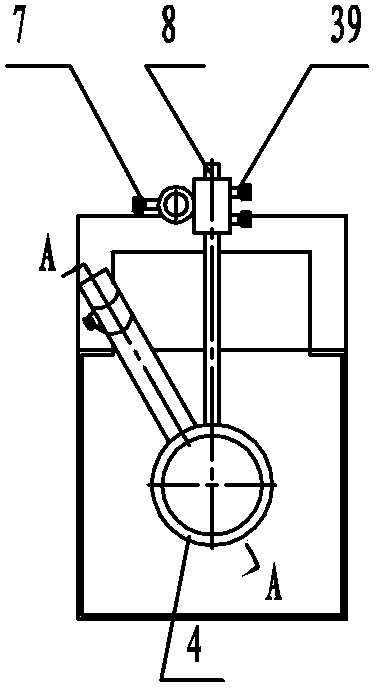

Melt liquid raising device for multi-station parallel-connection pressurizing cast device

InactiveCN108788093AGuaranteed processing temperatureGuaranteed safe operating temperatureButt jointEngineering

The invention discloses a melt liquid raising device for a multi-station parallel-connection pressurizing cast device. The melt liquid raising device is characterized by comprising a liquid raising pipe upper section, a liquid raising pipe lower section and a heat preserving cover arranged on the liquid raising pipe upper section in a wrapping manner. The liquid raising pipe upper section is connected with a liquid filling opening. The liquid raising pipe lower section extends in a melt partially. The liquid raising upper section and the liquid raising pipe lower section are in butt joint through a motion mechanism. The melt liquid raising device is easy to install and convenient to operate, the use process is safe and reliable, the technological process is distinct and high in stability,volume production is achieved in multi-station parallel-connection pressurizing cast of large aluminum alloy frameworks, plates and cabin components, application and popularization value is high, andthe industrial potential is great.

Owner:NO 59 RES INST OF CHINA ORDNANCE IND

Garbage combustion furnace high in combustion efficiency

The invention discloses a garbage combustion furnace high in combustion efficiency. Household garbage is put into a furnace chamber of the combustion furnace from the top of the combustion furnace, and air is fed into the furnace chamber from the bottom, so that the garbage is combusted from bottom to top, and waste residues are discharged through a residue discharging port in the bottom. Final tail gas of garbage combustion is exhausted from the lower portion of the furnace chamber after being combusted sufficiently, so that the temperature inside the furnace chamber is decreased gradually from bottom to top. According to the garbage combustion equipment which is optimized in design and is high in gas circulation efficiency, the lower portion of a furnace body can be effectively cooled through an annular cooling chamber arranged outside the furnace body; meanwhile, on one hand, the air is preheated after flowing through the periphery of the upper portion of the furnace body and then enters the furnace chamber, so that the situation that cold air enters the furnace chamber, and consequently the temperature in the furnace chamber and the combustion efficiency in the furnace chamber are influenced is avoided; on the other hand, the air enters the furnace chamber uniformly from the bottom of the furnace chamber, so that uniform combustion in the furnace chamber is guaranteed, the air utilization rate is greatly increased, the treatment temperature in the furnace chamber is guaranteed, and the combustion efficiency in the furnace chamber is greatly improved; and furthermore, the tail gas is exhausted after being cooled through the cooling chamber, and accordingly the subsequent tail gas treatment is facilitated.

Owner:湖南未名环保科技有限公司

Heating device for use in spray of tire leakproof glue

InactiveCN101637745AIngenious structural designReduce energy consumptionLiquid surface applicatorsSpray nozzlesHeating efficiencyClosed cavity

The invention provides a heating device for use in the spray of tire leakproof glue. The heating device comprises a leakproof glue liquid tube; an oil delivery tube for heating is arranged beside theleakproof glue liquid tube; the outer surfaces of the leakproof glue liquid tube and the oil delivery tube are sleeved with an outer sleeve tube capable of forming a closed cavity, the back end of theouter sleeve tube is provided with an oil inlet and an oil outlet, and the oil inlet is directly connected with the back end of the oil delivery tube in the outer sleeve tube; and the oil outlet at the front end of the oil delivery tube is arranged in the closed cavity of the outer sleeve tube on the side of a threading connector of a nozzle of the leakproof glue liquid tube. With a built-in oildelivery tube, the heating device has skillful design and compact structure, lowers energy consumption, improves heating efficiency, greatly reduces the volume of a heater, avoids the collision scratch between the heater and the inner edge of the rotating tire, and improves the safety of production personnel and equipment. When the heater works, the oil delivery tube for filling oil in the cavityis always immersed in the flowing high-temperature oil, so the constant temperature of the high-temperature oil, namely the process temperature of the leakproof liquid, is ensured.

Owner:上海华府轮胎科技发展有限公司

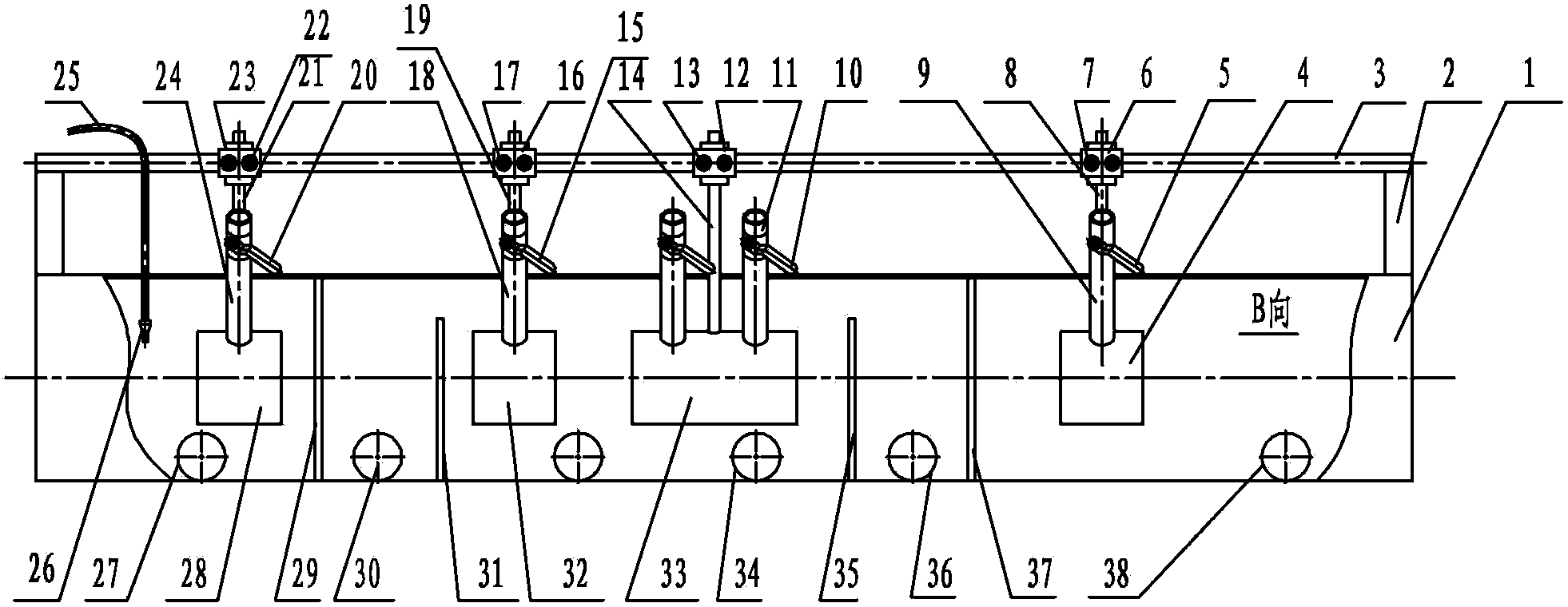

Method for production of high-strength threaded steel bar through on-line quenching and tempering, and heating blackening coating processes

ActiveCN102817038AGuaranteed StrengthSolve the mechanical propertiesFurnace typesHeat treatment furnacesInduction hardeningRebar

The invention relates to a method for production of high-strength threaded steel bar through on-line quenching and tempering, and heating blackening coating processes. The method includes the following steps of: subjecting a thread steel bar to multistage induction quenching heating, controlling the temperature of a quenching preheating zone at 700-850DEG C and the temperature of a quenching heat preservation zone at 820-950DEG C, and keeping the speed of quenching heating at 0.2-0.5m / min, then carrying out a quenching treatment, performing cooling at a cooling speed of 50-100DEG C / s, controlling the temperature of the thread steel bar released out of a spray ring cooling device at 60-100DEG C, then performing multistage induction tempering heating at a proceeding speed of 0.2-0.5m / min, controlling the tempering temperature at 500-650DEG C, delivering the tempered threaded steel bar to a surface coating zone to conduct heating blackening antiseptic treatment, implementing online packaging, and finally conducting offline storage. The technological method realizes on-line quenching and tempering, and heating blackening production of high-strength threaded steel bars, and has the characteristics of small deformation of workpieces, high production efficiency, energy saving, environmental protection, and less pollution, etc.

Owner:LIUZHOU OVM MASCH CO LTD

Gear grinding running-in and extruding type feed grinder

The invention relates to a gear grinding running-in and extruding type feed grinder. The feed grinder comprises a feed hopper, a discharge hopper, a motor and a grinding and mixing device which are arranged on a rack. The grinding and mixing device comprises an inner grinding shell driven by the motor and an outer grinding barrel arranged on the periphery of the inner grinding shell. The outer grinding barrel is installed on the rack. The inner grinding shell and the outer grinding barrel are of conical structures. Multiple grinding teeth mutually staggered are arranged on the outer wall of the inner grinding shell and the inner wall of the outer grinding barrel. An extruding space is reserved between the lower conical end of the outer grinding barrel and the lower conical end of the inner grinding shell. A filtering plate fixedly connected to the lower end of the outer grinding barrel is arranged under the extruding space. The discharge hopper is arranged under the filtering plate. Annular feed grooves are formed in the upper end of the inner grinding shell and the upper end of the outer grinding barrel and communicated with an outlet of the feed hopper. Multiple electric heating pieces are installed on the side wall of the outer grinding barrel in an embedded mode.

Owner:WUXI SHUANGSHI MACHINERY CO LTD

Graphite purification equipment

ActiveCN103723719BGuarantee the quality of purificationGuaranteed purification effectCarbon compoundsElectrical resistance and conductanceGraphite

The invention provides a graphite purifying device. The device comprises a feeding system, a purifying furnace and a discharging system which are sequentially arranged in vertical direction, wherein the purifying furnace comprises a muffle for purifying and heating graphite and a resistance heating device surrounding the muffle in circumferential direction. The graphite purifying device works in vertical direction, the feeding system feeds a graphite material at the top of the purifying furnace, the graphite is purified in the purifying furnace and is discharged by the discharging system at the bottom of the purifying furnace, the graphite material is purified in the muffle, and the resistance heating device is used for guaranteeing the processing temperature in the muffle so as to realize heating at high temperature to guarantee the quality of graphite purifying. Due to structural design of the graphite purifying device with the vertical structure, the graphite can be purified continuously at high temperature, so that the production efficiency is improved, and the graphite purifying effect is guaranteed.

Owner:ADVANCED FOR MATERIALS & EQUIP

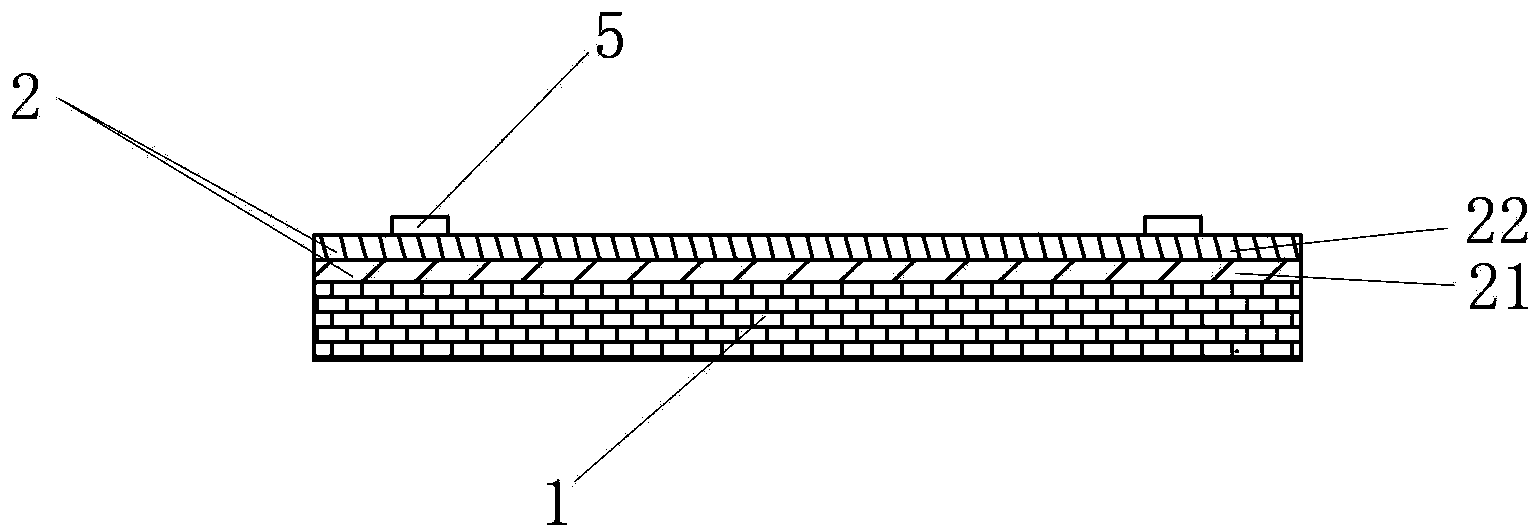

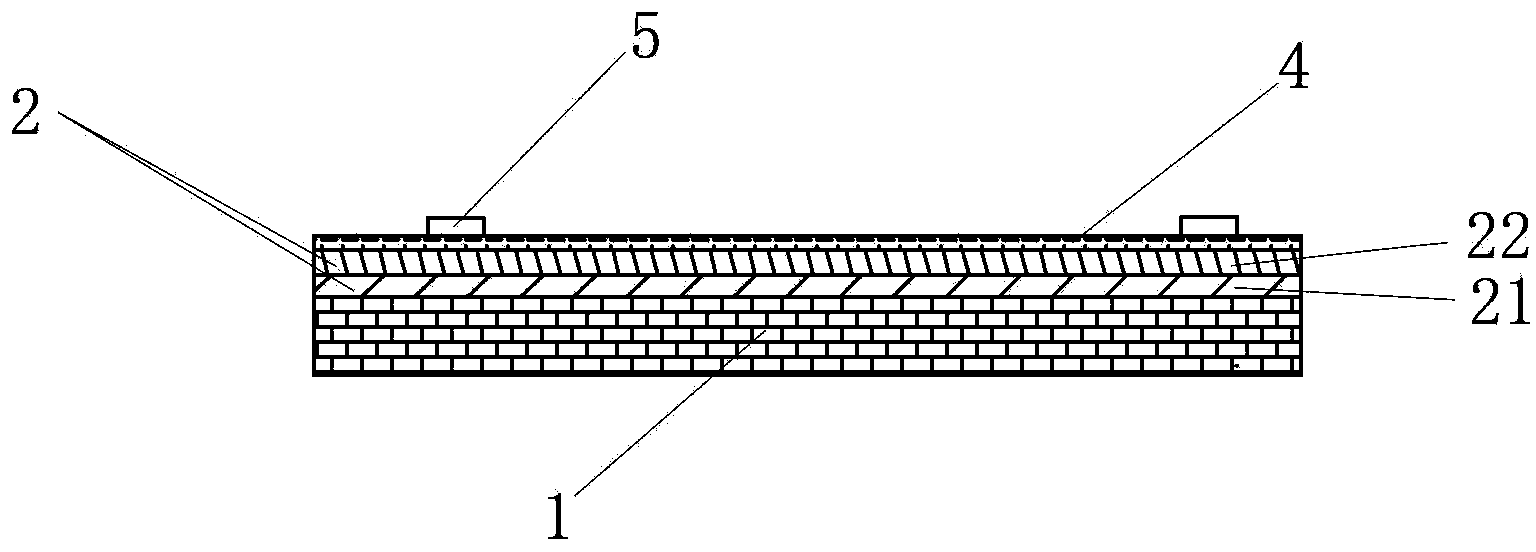

Insulation apparatus for glass tank furnace

InactiveCN103387325AEvenly distributedReduced insulation performanceGlass furnace apparatusFiberGlass fiber

The invention discloses an insulation apparatus for a glass tank furnace. The insulation apparatus comprises, from interior to exterior, a heat insulation composite layer, an insulation composite layer, a reflecting layer and a fixing part, wherein the heat insulation composite layer is mainly composed of an alumina silicate fiber blanket layer and a first aerogel insulation blanket layer, the alumina silicate fiber blanket layer and the first aerogel insulation blanket layer are successively, from interior to exterior, laid and covered on the external side surfaces of all the positions of the glass tank furnace provided with an insulation layer, the insulation composite layer is composed of a glass fibrofelt layer or rock wool layer and an aerogel insulation blanket layer, the reflecting layer is an aluminum plate or galvanized sheet iron, and the fixing part is arranged out of the reflecting layer to allow the heat insulation composite layer, the insulation composite layer and the reflecting layer to be tightly compacted on the external surface of the insulation layer of the glass tank furnace. The insulation apparatus for the glass tank furnace in the invention is applied at the outer side of the insulation layer of a traditional float glass tank furnace, enables heat dissipation quantity of the insulation layer of the traditional glass tank furnace to be greatly reduced and has a substantial secondary insulation effect on the glass tank furnace.

Owner:常州循天节能科技有限公司

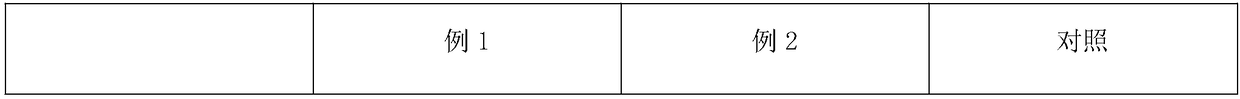

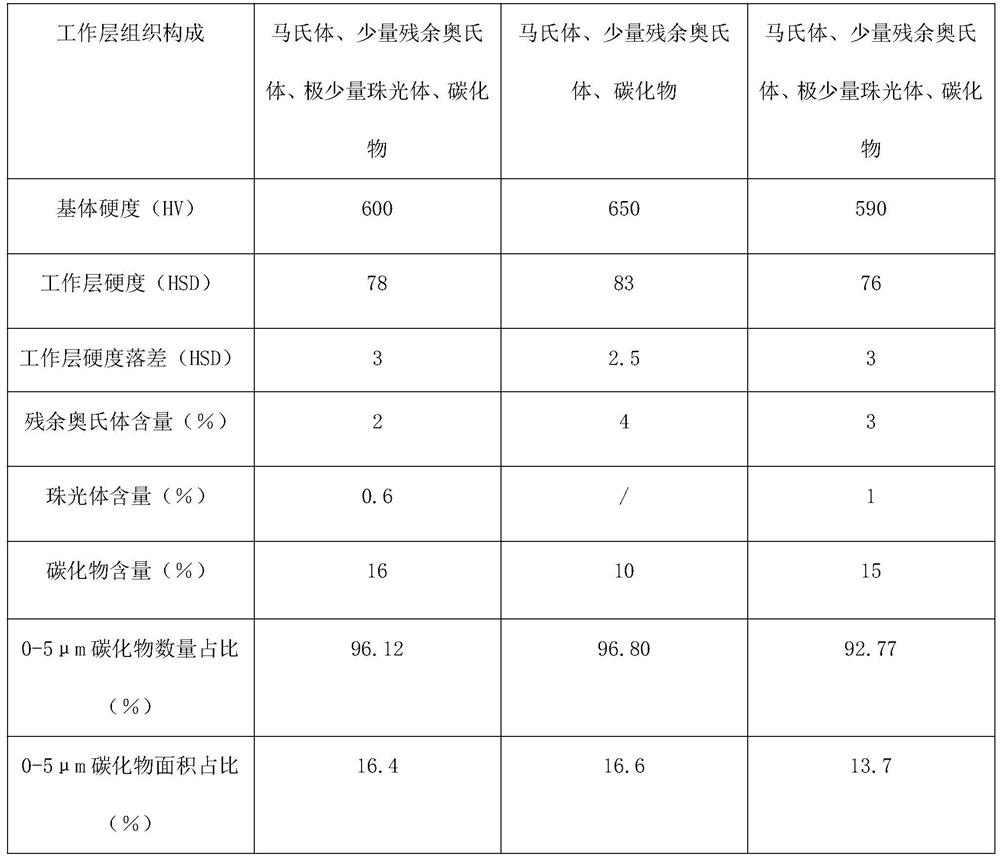

Preparation method of high-alloy centrifugal roller

ActiveCN108115105AImprove performanceSimple production processFurnace typesHeat treatment furnacesAlloyQuenching

The invention discloses a preparation method of a high-alloy centrifugal roller, and belongs to the field of preparation of rollers. The high-alloy centrifugal roller comprises a working layer and a core portion. The preparation method includes the steps: slowly cooling the rollers; rapidly reducing temperature; annealing at lower temperature. According to the method, solidification and cooling processes and annealing temperature and time of the rollers are reasonably controlled, high-temperature quenching of a preparation process of the high-alloy centrifugal roller is omitted, so that production processes are simplified, device investment is reduced, a production cycle is shortened, production cost is reduced, and the roller meets requirements and is stable in performance.

Owner:SINOSTEEL XINGTAI MACHINERY & MILL ROLL

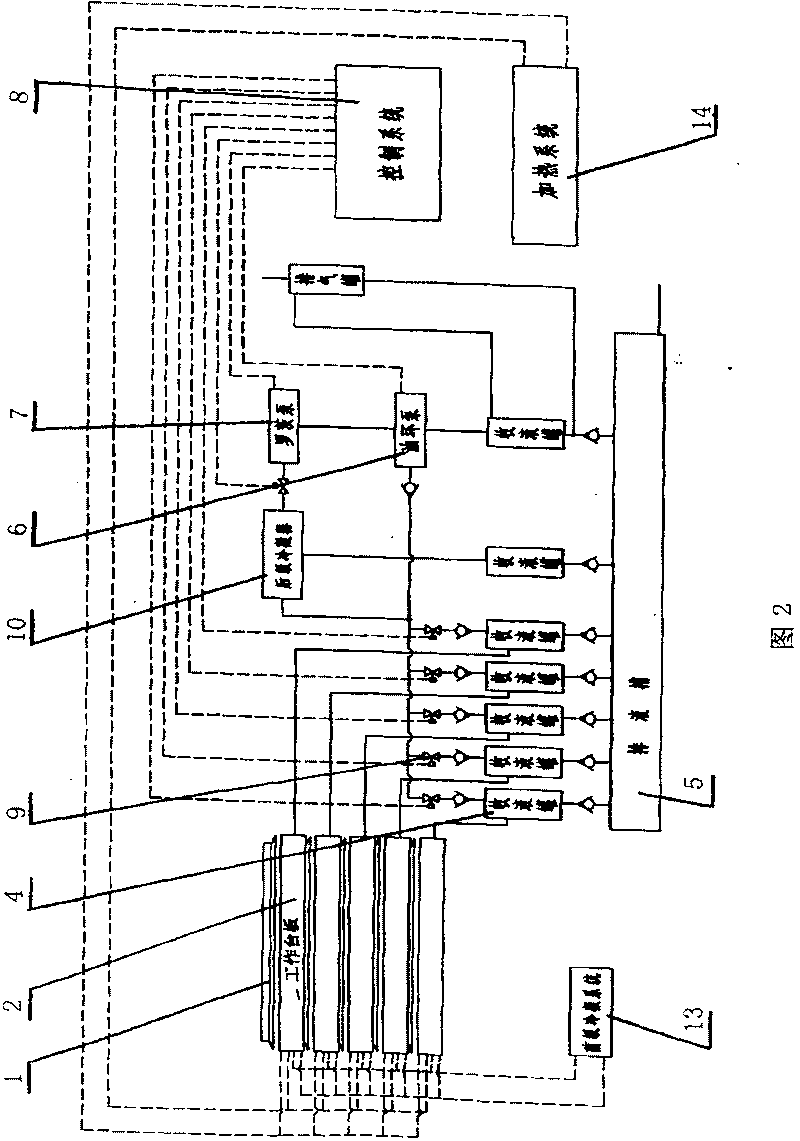

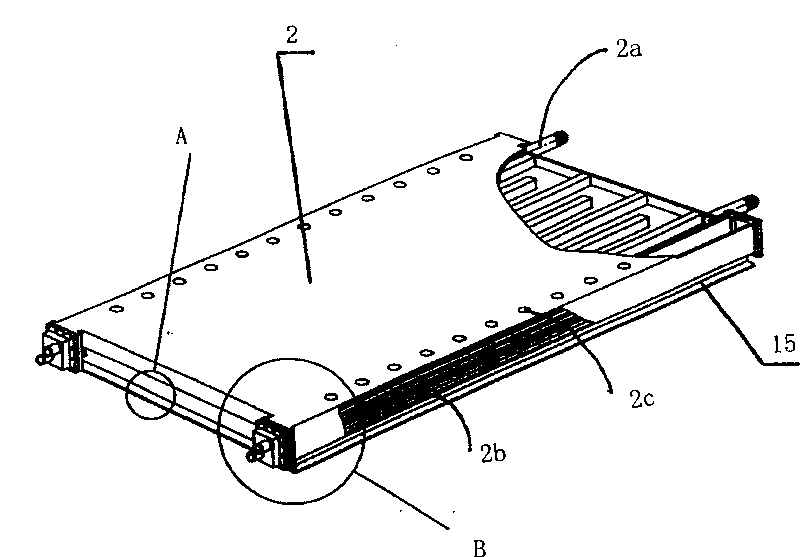

Drill bit heat treatment equipment for mine

InactiveCN108950168AConvenient heat treatmentShorten production timeFurnace typesHeat treatment furnacesHeat treatedPetroleum engineering

The invention discloses drill bit heat treatment equipment for a mine. The drill bit heat treatment equipment comprises a working platform. A fixing supporting bracket is fixedly arranged above the working platform. A controller is arranged on one side of the fixing supporting bracket. A lifting block is arranged on one side of the fixing supporting bracket in a sleeving mode. A horizontal guide rod is fixedly arranged on the inner side of the lifting block. A moving device is arranged on one side of the horizontal guide rod. A telescopic motor is fixedly arranged on one side of the moving device. A telescopic rod is arranged on the inner side of the telescopic motor. A drill bit fixing device is fixedly arranged below the telescopic rod. The drill bit heat treatment equipment has the beneficial effects that through cooperation between the lifting block and the moving device, movement of the drill bit fixing device can be achieved, and three processes of heat treatment can be achieved.Through action of the telescopic motor and the telescopic rod, distance between the telescopic motor and a working station can be retained to prevent motor damage caused by excessive temperature of the telescopic motor due to too close distance. Through the drill bit fixing device, a drill bit can be fixed, and therefore heat treatment of the drill bit can be convenient, a plurality of drill bitscan be treated at the same time, and production time of the drill bit can be shortened.

Owner:金双悦

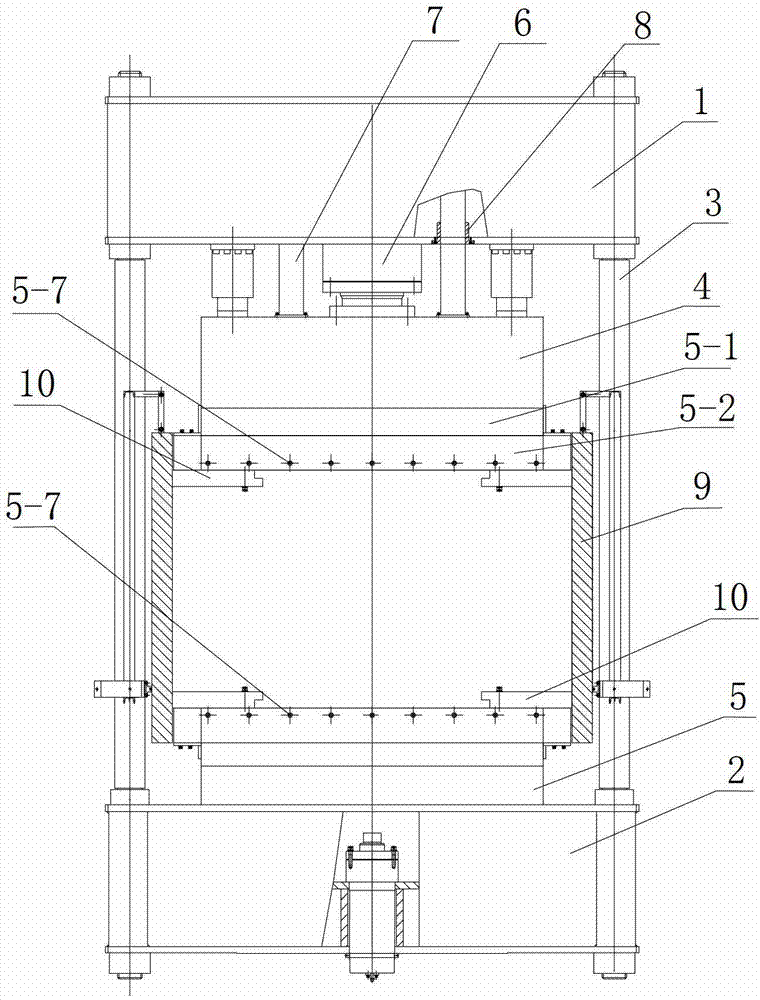

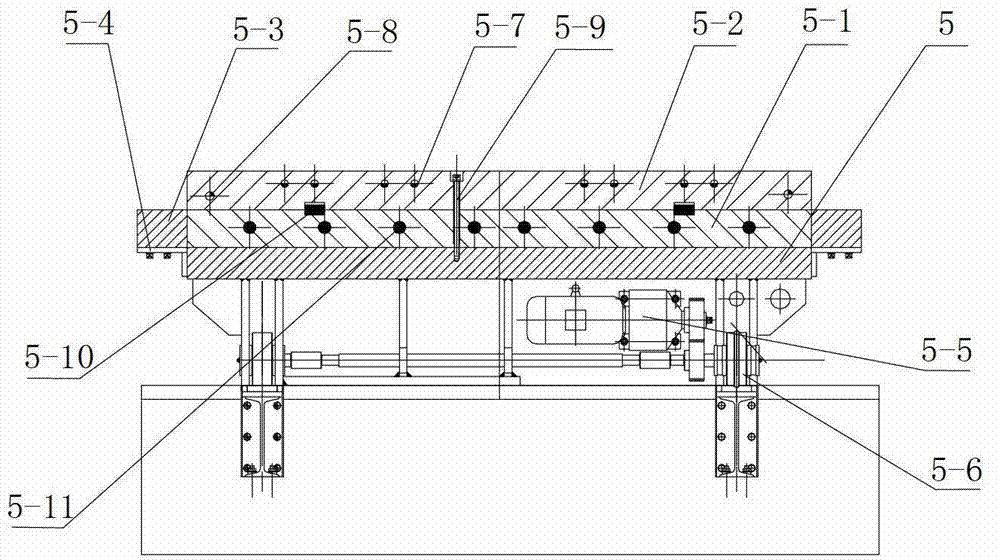

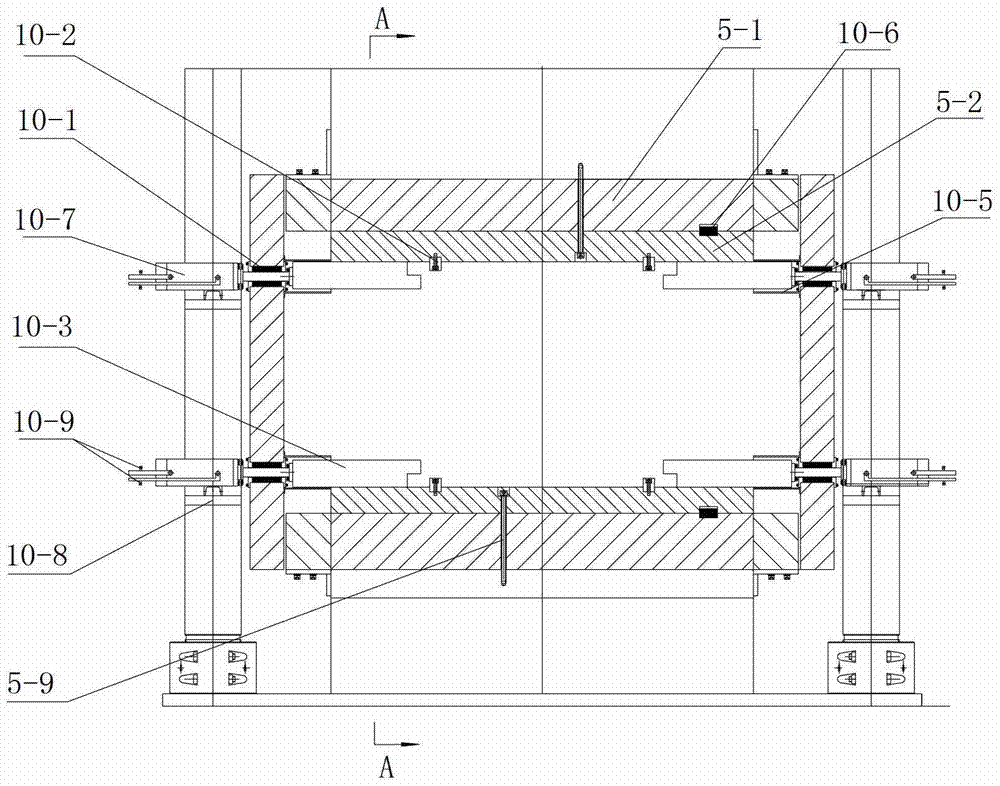

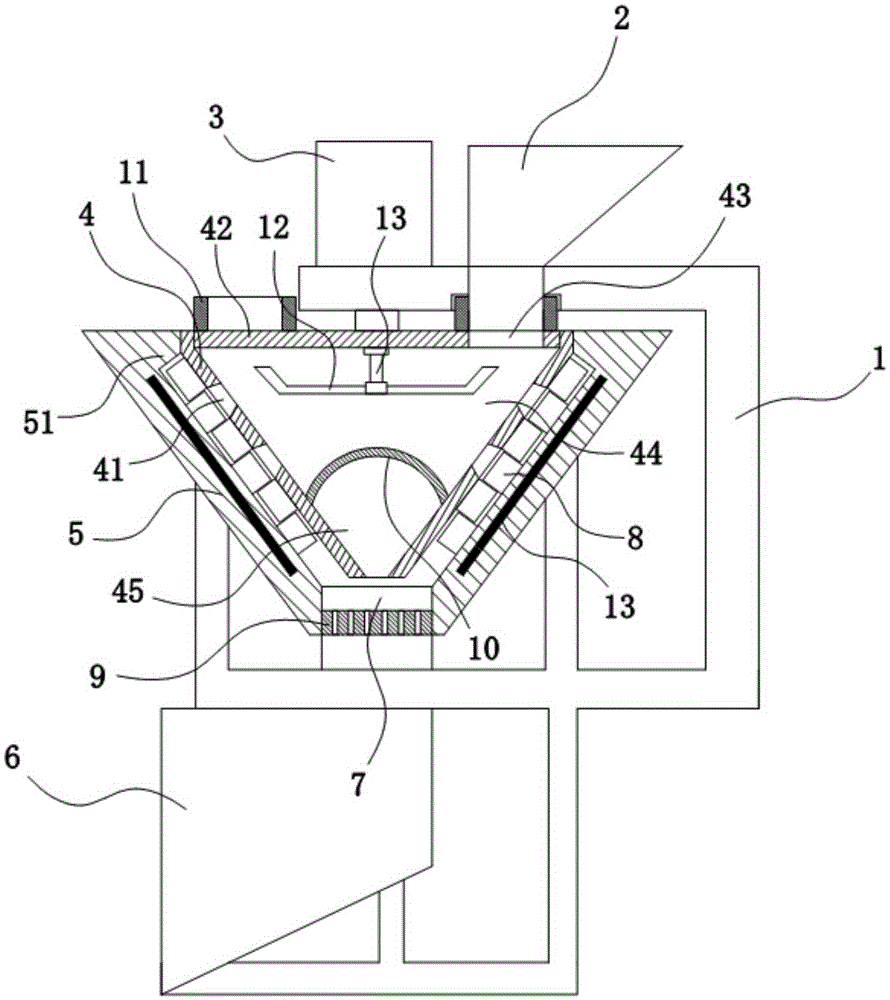

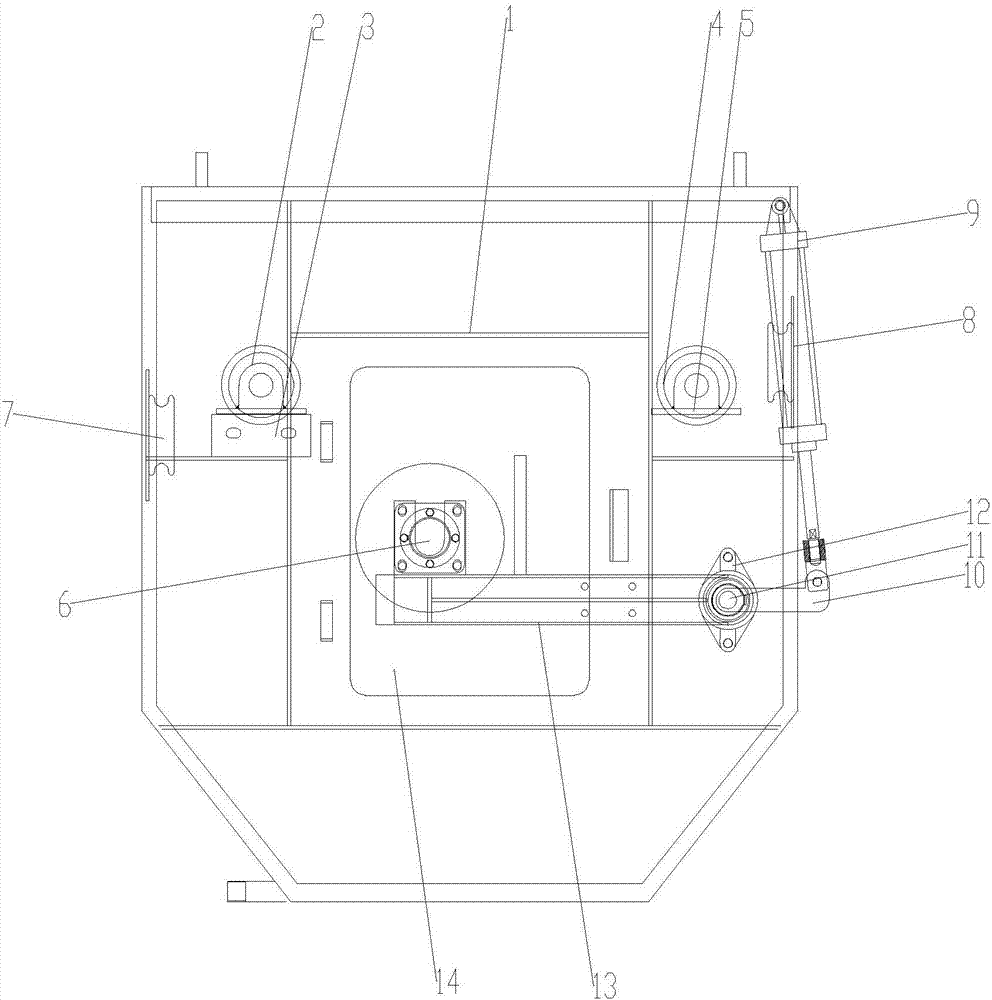

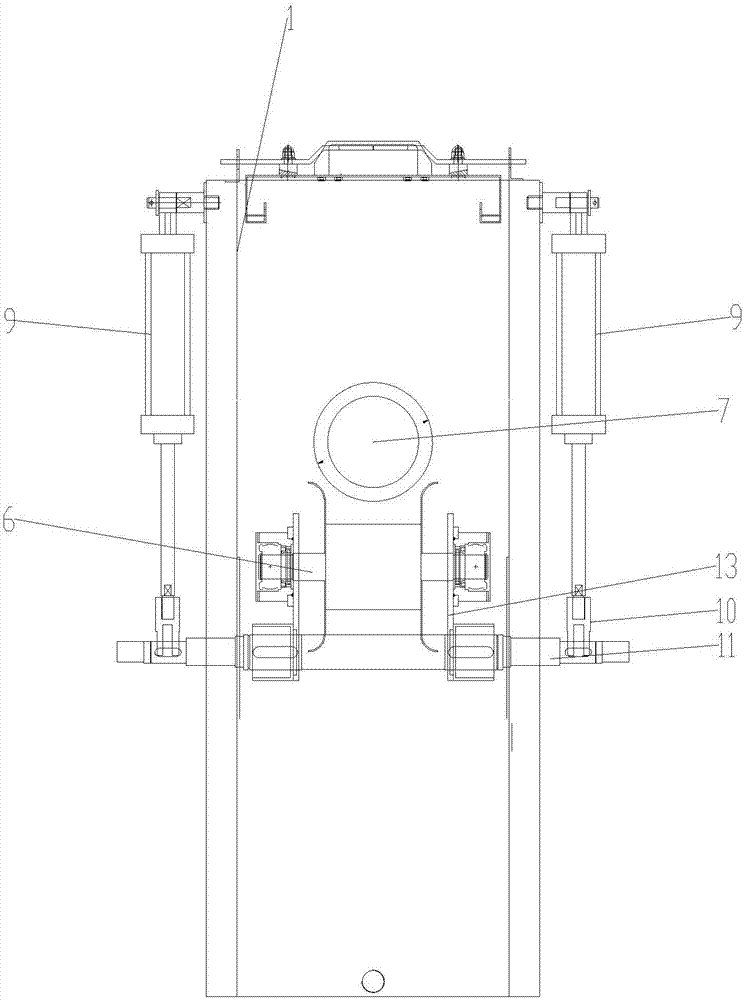

It can realize isothermal hot forming forging press for hot sheet metal parts

ActiveCN102909302BAvoid damageRealize hot pressingForging/hammering/pressing machinesForging press detailsMetal sheetTitanium alloy

The invention relates to a forging machine capable of realizing constant-temperature thermal forming of hot metal sheet parts. The forging machine comprises a machine body, a working cylinder, a sliding block and a working platform, and is characterized in that the working platform is a movable working platform; the upper plane of the movable working platform and the lower plane of the sliding block are respectively and fixedly provided with a high-temperature-resistant metal cushion plate and a ceramic plate by fasteners in a one-step manner; the ceramic plate is internally provided with a heating unit; the lower plane of the ceramic plate of the sliding block and the upper plane of the ceramic plate of the movable working platform are respectively provided with a mold quick-clamping mechanism; and the periphery of the working area of the forging machine is provided with an insulating device. The forging machine has the advantages that the full maintenance of the temperature of the working area in the forging process under the high-temperature state can be realized, and the constant-temperature pressing of hot metal sheet parts is realized; the temperature loss is reduced to be the lowest, the energy can be greatly saved, the processing cost can be reduced, the forging quality and the production efficiency of a product are improved, and further the processing need to titanium-alloy constant-temperature thermal forming parts of airplanes in the aerospace industry is met.

Owner:TIANJIN TIANDUAN PRESS CO LTD

An adjustable cooling device for industrial heating furnace

ActiveCN108800951BTo achieve the purpose of heat dissipationIncrease temperatureFurnace coolingCombustionEngineering

The invention discloses an adjustable heat dissipation device for an industrial heating furnace. The adjustable heat dissipation device comprises a heating furnace, a heat dissipation top plate, a topend fixing plate and a heat dissipation box, wherein a combustion furnace is arranged at the bottom of the heating furnace, a heat dissipation top plate is arranged on the upper surface of the heating furnace, a heat dissipation top plate is arranged above the industrial heating furnace in the device, the heat dissipation top plate can be selected to be attached to or not attached to the upper surface of the heating furnace according to actual requirements, so that the purpose of radiating the heating furnace is achieved, the heat dissipation effect is achieved when the temperature inside theheating furnace is too high, it is guaranteed that the temperature in the heating furnace is not too high, the internal temperature of the heating furnace is within a stable temperature fluctuation range, the normal processing temperature of surface treatment is guaranteed, a heat dissipation top plate is added above the heating furnace, and the purpose of cooling when the heating furnace is initially heated or the temperature is too high when the heating temperature is too high is achieved, the temperature in the furnace can be controlled to fluctuate within a certain range, heat dissipationcan be carried out by exceeding the maximum temperature value, and the device is convenient to use.

Owner:中高(泰州)知识产权管理咨询有限公司

Novel feed grinding machine

InactiveCN105266180AImprove efficiencyReduce resistanceFeeding-stuffArchitectural engineeringGrinding teeth

The invention relates to a novel feed grinding machine. The novel feed grinding machine comprises a feed hopper, a discharge hopper, a motor and a crushing and mixing device which are all arranged on a machine frame. The crushing and mixing device comprises an inner grinding block driven by the motor and an outer grinding barrel installed on the periphery of the inner grinding block, and the outer grinding barrel is installed on the machine frame. The inner grinding block and the outer grinding barrel are both of a conical structure, the outer wall of the inner grinding block and the inner wall of the outer grinding barrel are provided with a plurality of staggered grinding teeth, the conical lower end of the outer grinding barrel and the conical lower end of the inner grinding block are provided with an extruding space, the lower portion of the extruding space is provided with a filtering plate fixedly connected to the lower end of the outer grinding barrel, and the discharge hopper is arranged below the filtering plate. An annular feeding groove is formed in the upper end of the inner grinding block and the upper end of the outer grinding barrel and communicated with an outlet of the feed hopper. A plurality of electric heating sheets which are arranged at intervals are embedded in the side wall of the outer grinding barrel.

Owner:WUXI SHUANGSHI MACHINERY CO LTD

A garbage incinerator with high combustion efficiency

The invention discloses a garbage combustion furnace high in combustion efficiency. Household garbage is put into a furnace chamber of the combustion furnace from the top of the combustion furnace, and air is fed into the furnace chamber from the bottom, so that the garbage is combusted from bottom to top, and waste residues are discharged through a residue discharging port in the bottom. Final tail gas of garbage combustion is exhausted from the lower portion of the furnace chamber after being combusted sufficiently, so that the temperature inside the furnace chamber is decreased gradually from bottom to top. According to the garbage combustion equipment which is optimized in design and is high in gas circulation efficiency, the lower portion of a furnace body can be effectively cooled through an annular cooling chamber arranged outside the furnace body; meanwhile, on one hand, the air is preheated after flowing through the periphery of the upper portion of the furnace body and then enters the furnace chamber, so that the situation that cold air enters the furnace chamber, and consequently the temperature in the furnace chamber and the combustion efficiency in the furnace chamber are influenced is avoided; on the other hand, the air enters the furnace chamber uniformly from the bottom of the furnace chamber, so that uniform combustion in the furnace chamber is guaranteed, the air utilization rate is greatly increased, the treatment temperature in the furnace chamber is guaranteed, and the combustion efficiency in the furnace chamber is greatly improved; and furthermore, the tail gas is exhausted after being cooled through the cooling chamber, and accordingly the subsequent tail gas treatment is facilitated.

Owner:湖南未名环保科技有限公司

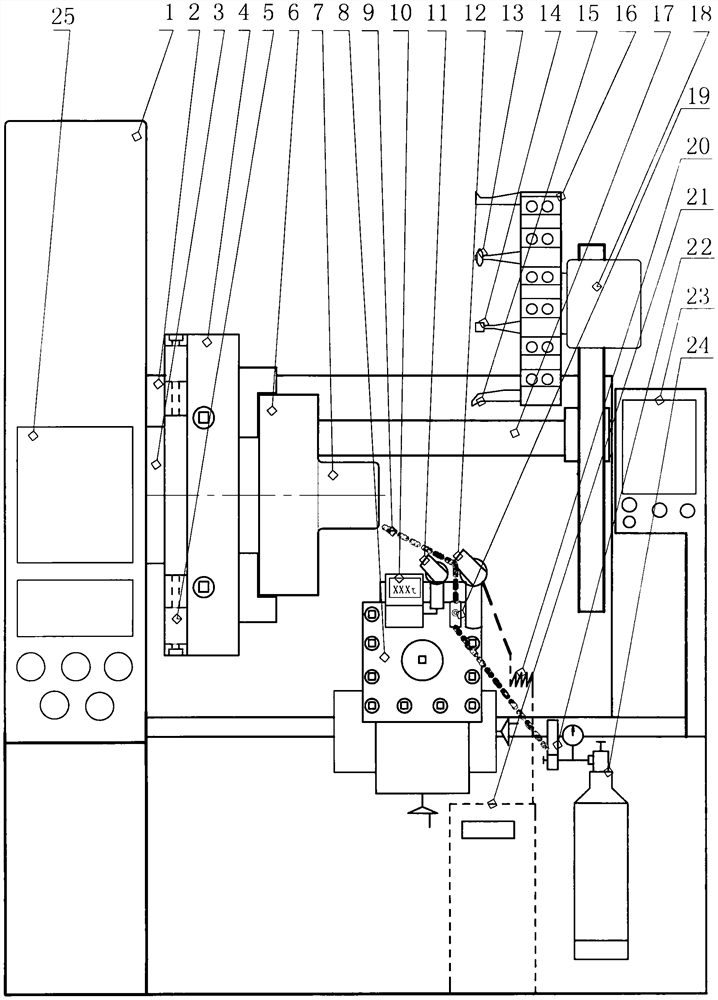

Numerical control machine tool with laser heating function

PendingCN112247167AIntelligently eliminate apparent defectsImprove qualityAuxillary equipmentMetal working apparatusNumerical controlEngineering

The invention provides a numerical control machine tool with a laser heating function. The numerical control machine tool comprises a numerical control machine tool mechanism, a carriage mechanism, aheating mechanism and a protection mechanism, wherein a dynamic balance detection instrument is arranged on the numerical control machine tool; a dynamic balance sense detector is arranged at the rootof a rotating shaft; an adjustable balance block is arranged in a chuck; a spinning head, a polishing head and a cutter are arranged on a numerical control cutter head; a control cabinet and the carriage mechanism are further arranged on the numerical control machine tool; a temperature measuring instrument, an automatic temperature measuring head and a numerical control laser head are arranged on a numerical control cutter rest of the numerical control machine tool; and a wire and a laser controller are arranged at the rear end of the numerical control laser head. The spinning head is adopted for spinning a machining section obtained after laser heating, so that pinholes and shrinkage porosity originally contained in the appearance are remolded and eliminated in the metal plasticizing state, the density is increased, and the appearance quality of the machining section meets the detection index; and the requirement for intelligently eliminating the appearance defects of castings is met, the rejection rate is saved, the quality of the castings is improved, and more benefits are generated.

Owner:WUXI XIYANGKANG SCI & TECH

Isothermal thermoforming hydraulic press

ActiveCN102935473BCompact structureReduce spanForging/hammering/pressing machinesForging press detailsThermal stateHeat resistance

The invention relates to an isothermal thermal forming forging machine which comprises a three-beam and four-column machine body, a working oil cylinder, a sliding block and a worktable, wherein the three-beam and four-column machine body is formed by an upper beam, a lower beam and columns. The isothermal thermal forming forging machine is characterized in that a guide column used for guiding the sliding block is arranged on the upper beam in penetrating mode, a guide sleeve is arranged between the upper beam and the guide column, and a heat resistance ceramic plate is fixedly arranged on the periphery of the lower plane of the sliding block. A high temperature resistance metal base plate and a ceramic base plate are sequentially fixedly arranged on the moving worktable through fastening parts, a ceramic coaming is fixed on the periphery of the ceramic base plate through a coaming bracket, and a heat preservation device is arranged on the periphery of a working area of the forging machine. The isothermal thermal forming forging machine has the advantages that temperature in the working area can be sufficiently kept in the high temperature forging process, and workpiece thermal state pressing can be achieved; temperature loss is reduced to be minimum, energy sources can be saved greatly, production cost is reduced, and product forging quality is improved; and further processing requirements of the aerospace industry for airplane titanium alloy thermal forming parts and other isothermal thermal forming parts are met.

Owner:TIANJIN TIANDUAN PRESS CO LTD

A kind of preparation method of high alloy centrifugal roll

ActiveCN108115105BImprove performanceSimple production processFurnace typesHeat treatment furnacesAlloyMaterials science

The invention discloses a preparation method of a high-alloy centrifugal roll, which belongs to the field of roll preparation. The high-alloy centrifugal roll includes a working layer and a core, and includes the steps of slowly cooling the roll, then rapidly cooling it, and then performing low-temperature annealing treatment. By rationally controlling the solidification and cooling process of the roll and the annealing temperature and time, the present invention saves the high-temperature quenching treatment in the preparation process of the high-alloy centrifugal roll, thereby simplifying the production process; reducing equipment investment, shortening the production cycle, and reducing the The production cost is reduced, and rolls that meet the requirements and have stable performance are obtained.

Owner:SINOSTEEL XINGTAI MACHINERY & MILL ROLL

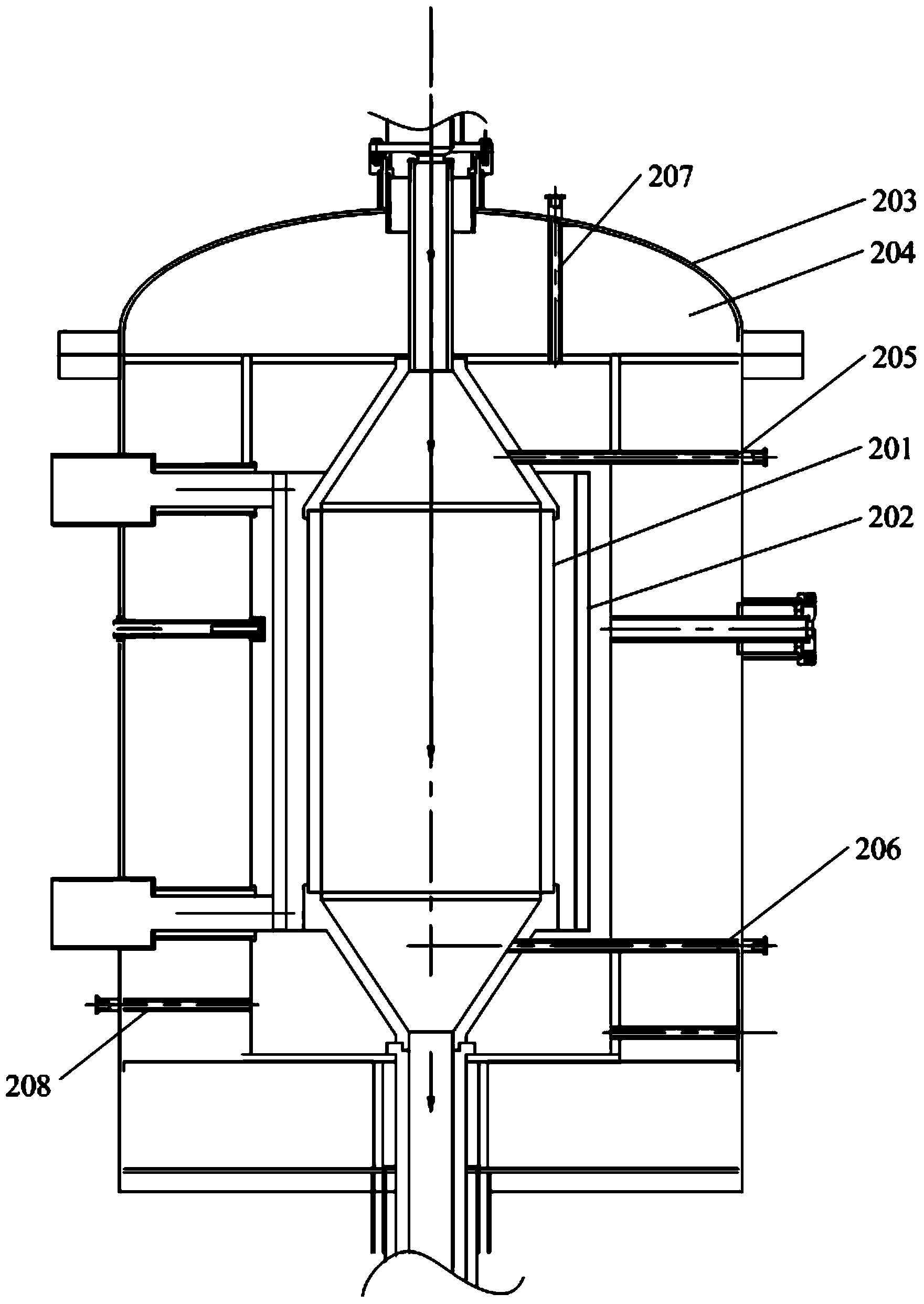

A gas cycle waste incinerator

InactiveCN105674277BGuaranteed processing temperatureImprove combustion efficiencyIncinerator apparatusEngineeringProduct gas

The invention discloses waste combustion equipment capable of achieving efficient gas circulation. Household waste is put into a furnace cavity of a combustion furnace from the top, and air is supplied into the furnace cavity from the bottom, so that the waste is combusted upwards from the bottom; and circulating gas at the top of the furnace cavity returns to the bottom of the furnace cavity for combustion supporting after moisture in the circulating gas is removed, and final tail gas generated during waste combustion is exhausted after being sufficiently combusted on the lower portion of the furnace cavity, so that the temperature in the furnace cavity is decreased gradually from bottom to top. Through the optically-designed waste combustion equipment capable of achieving efficient gas circulation, an annular cooling cavity arranged outside a furnace body can effectively cool the lower portion of the furnace body; meanwhile, in one aspect, air enters the furnace cavity after being preheated when flowing through the periphery of the upper portion of the furnace body, and thus the temperature in the furnace cavity is guaranteed; in another aspect, the tail gas is exhausted after being cooled through a cooling cavity, so that subsequent tail gas treatment is facilitated; and in another aspect, inlet circulating gas is preheated through outlet circulating gas, so that the heat utilization rate is greatly increased, the treatment temperature in the furnace cavity is guaranteed, high-temperature gas is effectively cooled before being exhausted, and the combustion efficiency in the furnace cavity is effectively improved.

Owner:SINOBIOWAY BIOENVIRONMENT CO LTD

Method for production of high-strength threaded steel bar through on-line quenching and tempering, and heating blackening coating processes

ActiveCN102817038BGuaranteed StrengthSolve the mechanical propertiesFurnace typesHeat treatment furnacesInduction hardeningRebar

The invention relates to a method for production of high-strength threaded steel bar through on-line quenching and tempering, and heating blackening coating processes. The method includes the following steps of: subjecting a thread steel bar to multistage induction quenching heating, controlling the temperature of a quenching preheating zone at 700-850DEG C and the temperature of a quenching heat preservation zone at 820-950DEG C, and keeping the speed of quenching heating at 0.2-0.5m / min, then carrying out a quenching treatment, performing cooling at a cooling speed of 50-100DEG C / s, controlling the temperature of the thread steel bar released out of a spray ring cooling device at 60-100DEG C, then performing multistage induction tempering heating at a proceeding speed of 0.2-0.5m / min, controlling the tempering temperature at 500-650DEG C, delivering the tempered threaded steel bar to a surface coating zone to conduct heating blackening antiseptic treatment, implementing online packaging, and finally conducting offline storage. The technological method realizes on-line quenching and tempering, and heating blackening production of high-strength threaded steel bars, and has the characteristics of small deformation of workpieces, high production efficiency, energy saving, environmental protection, and less pollution, etc.

Owner:LIUZHOU OVM MASCH CO LTD

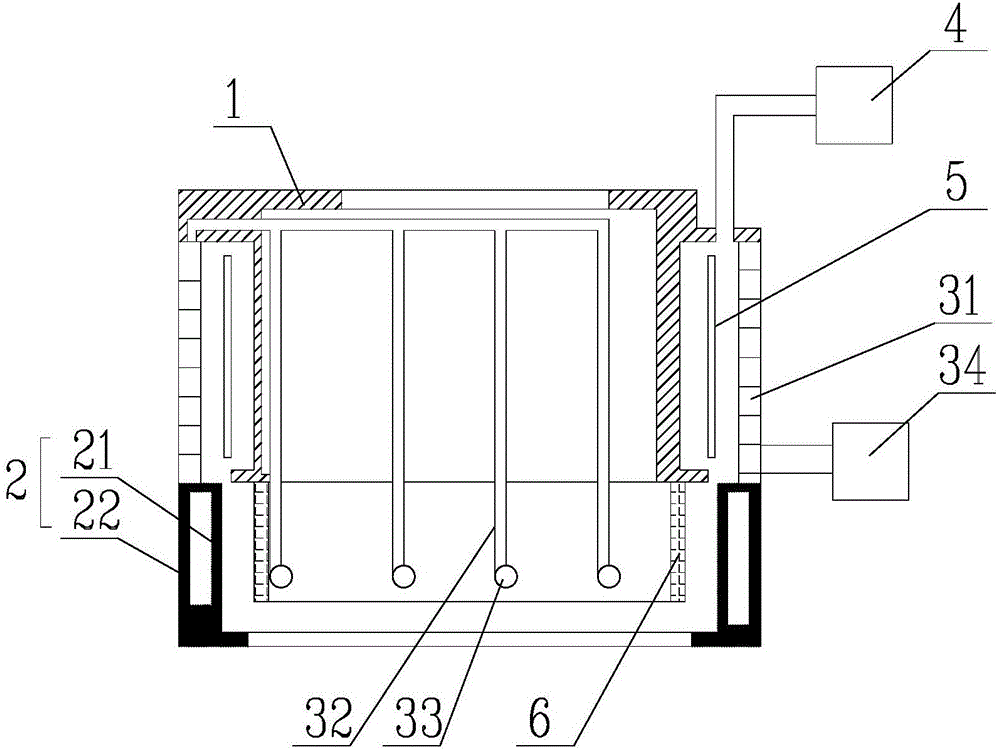

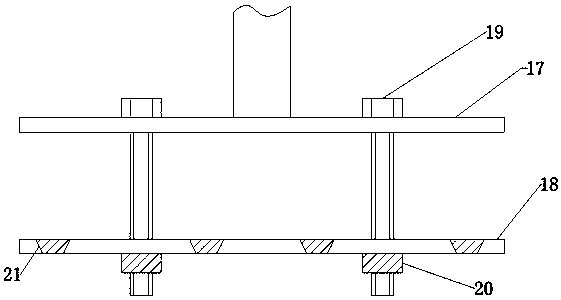

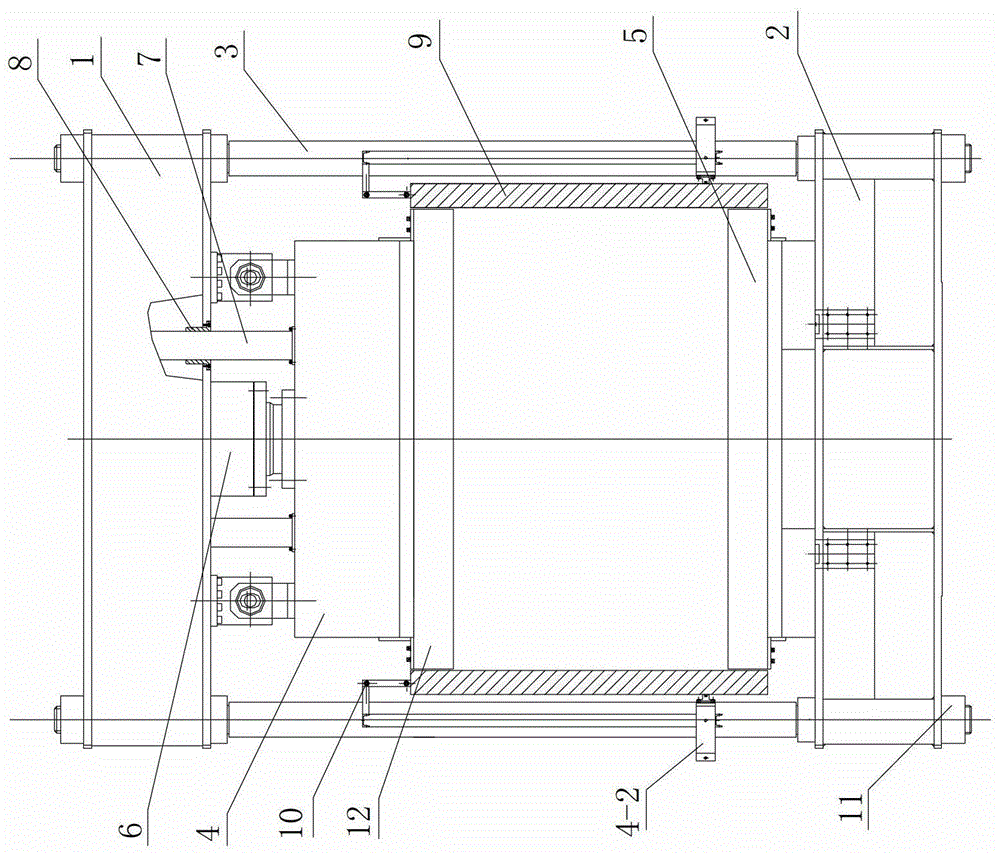

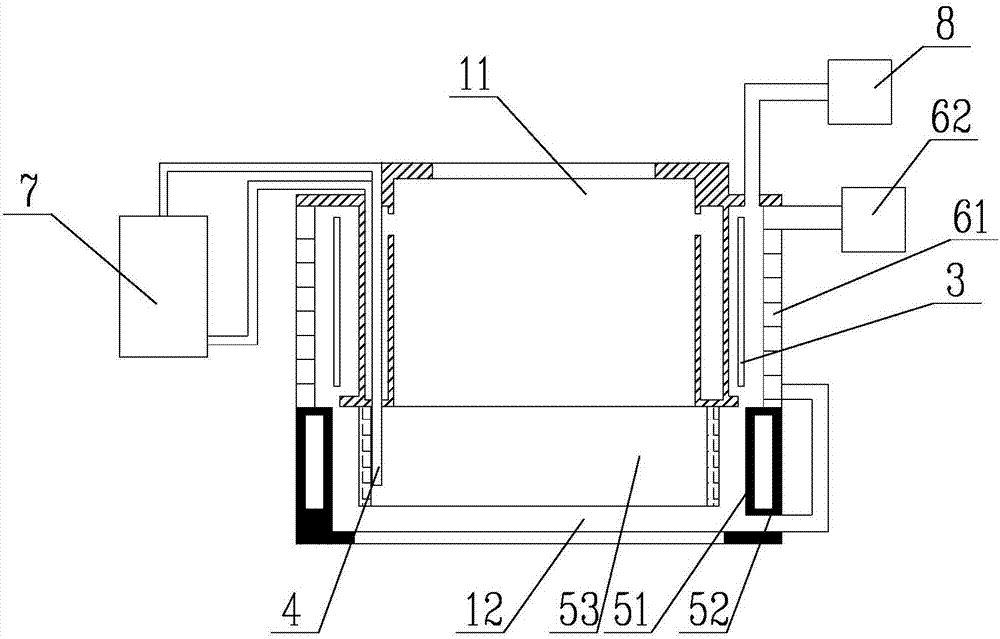

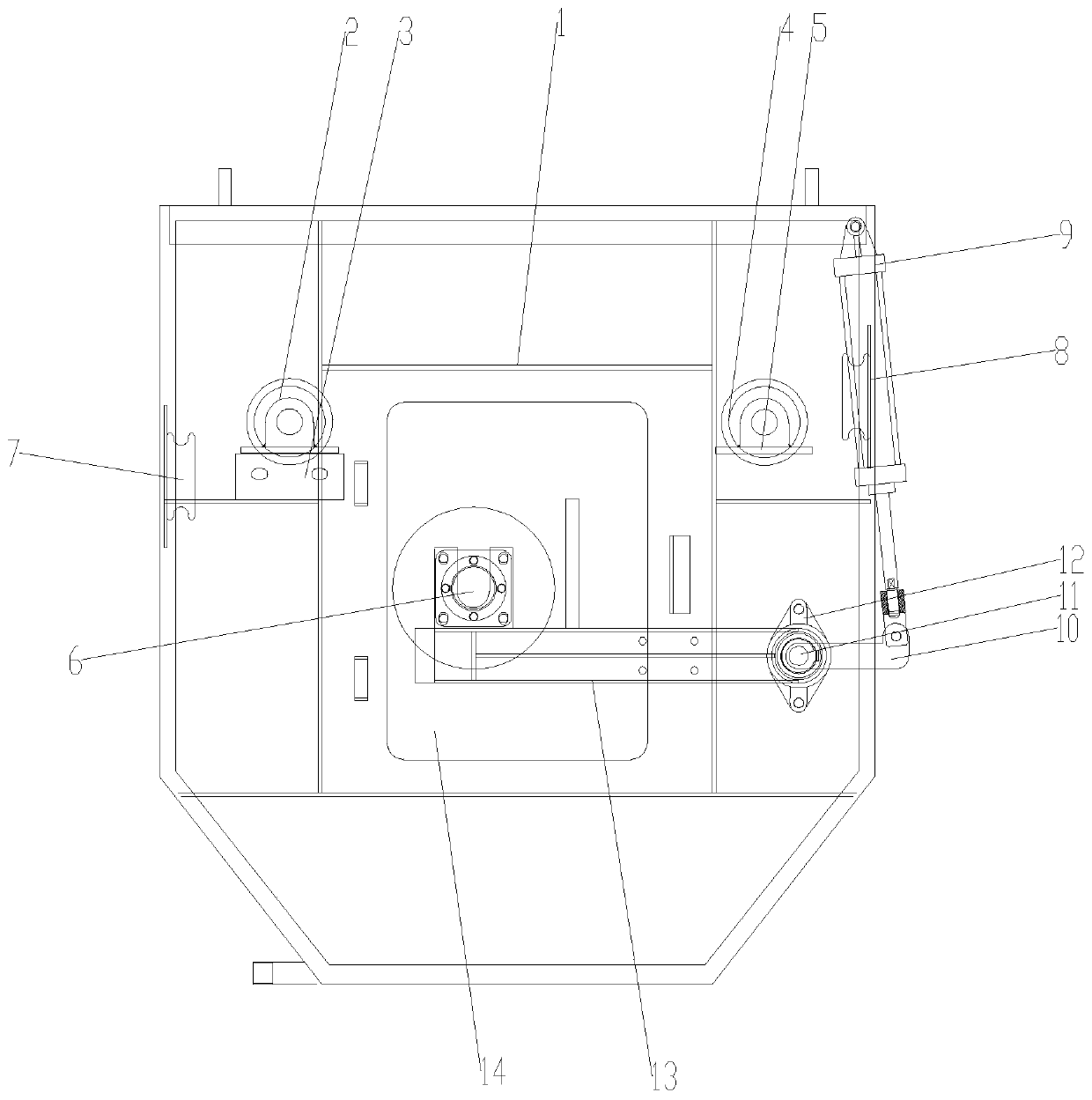

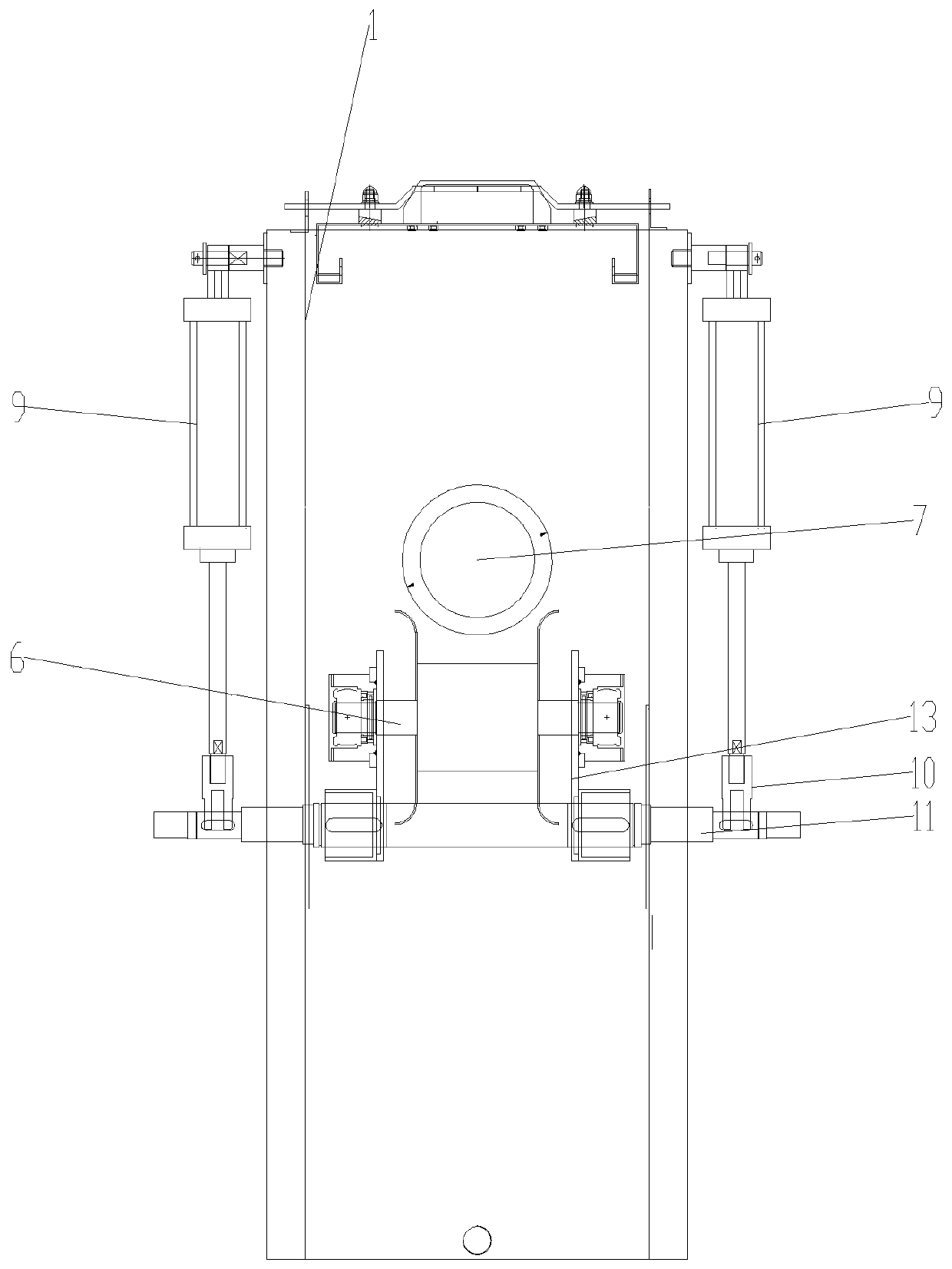

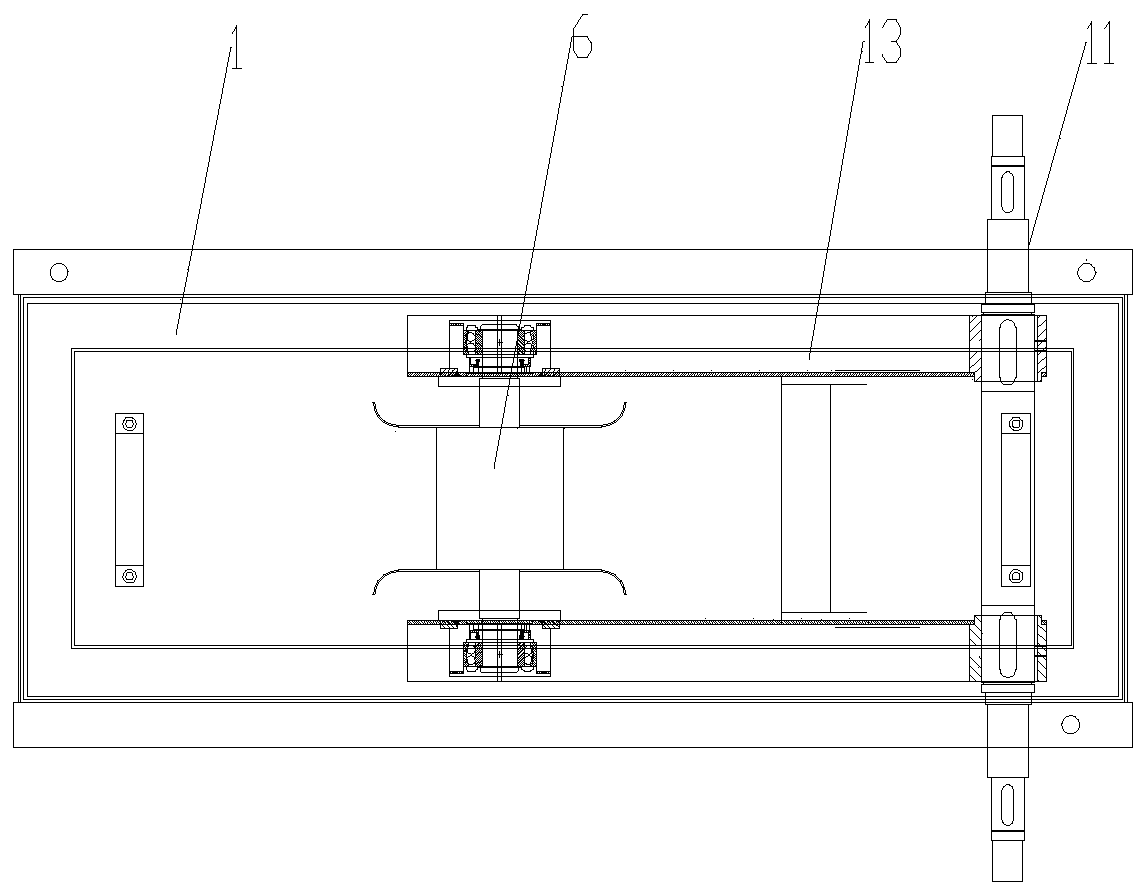

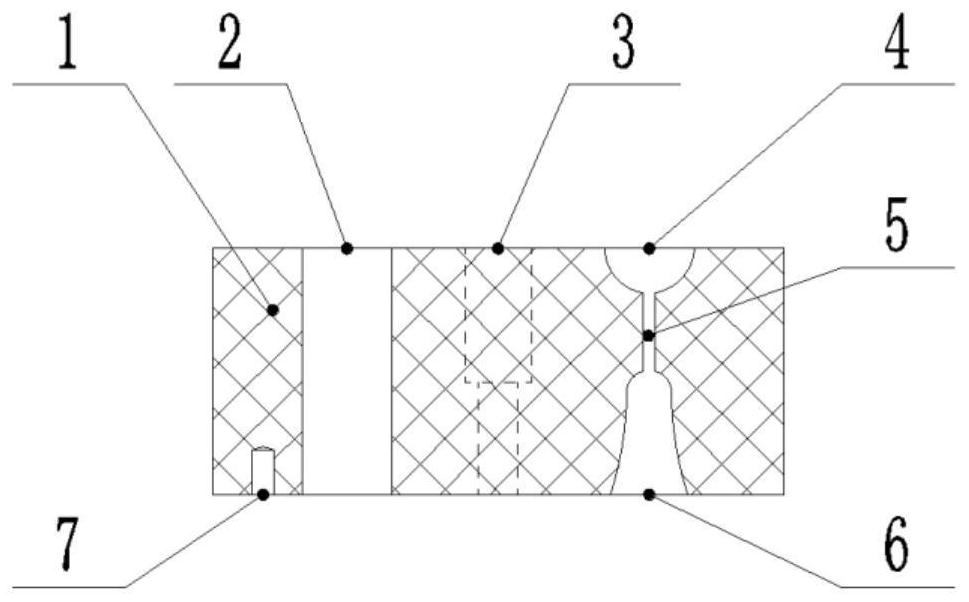

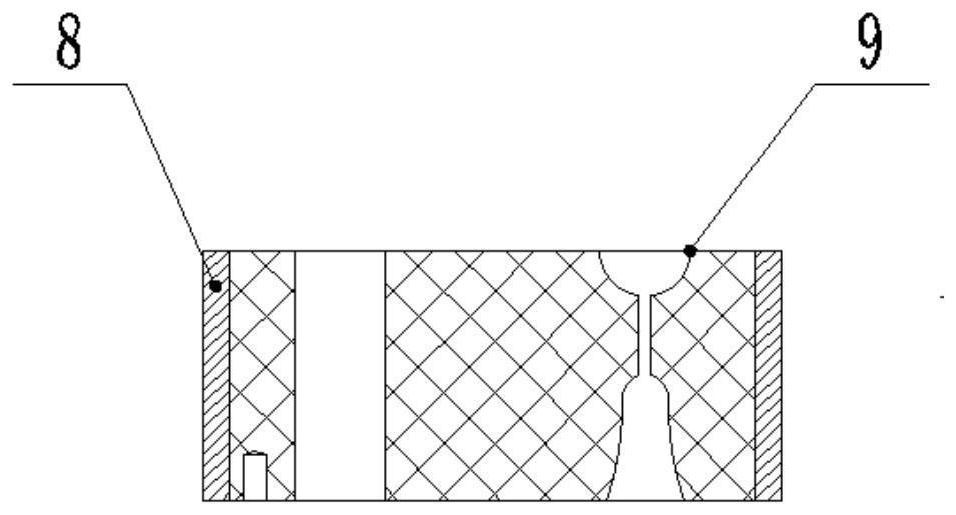

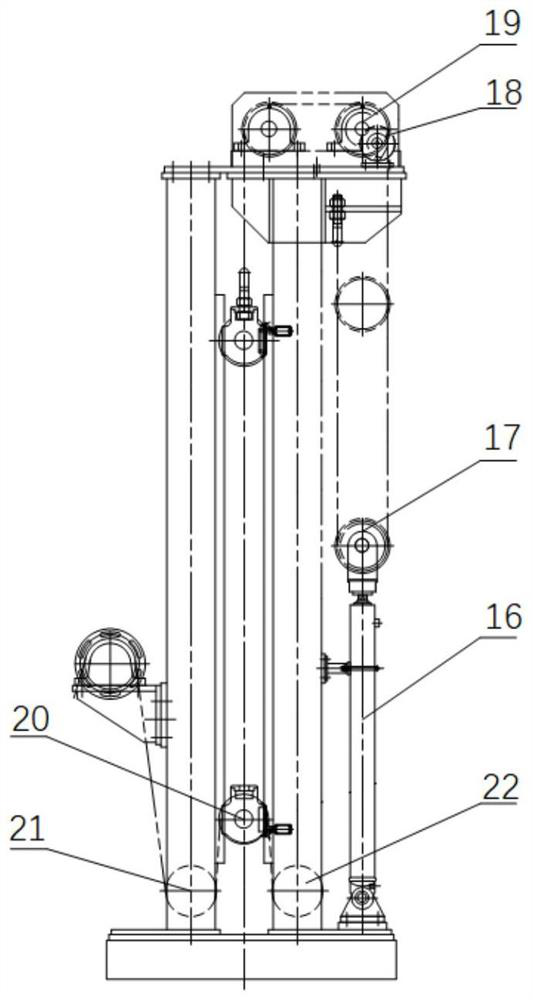

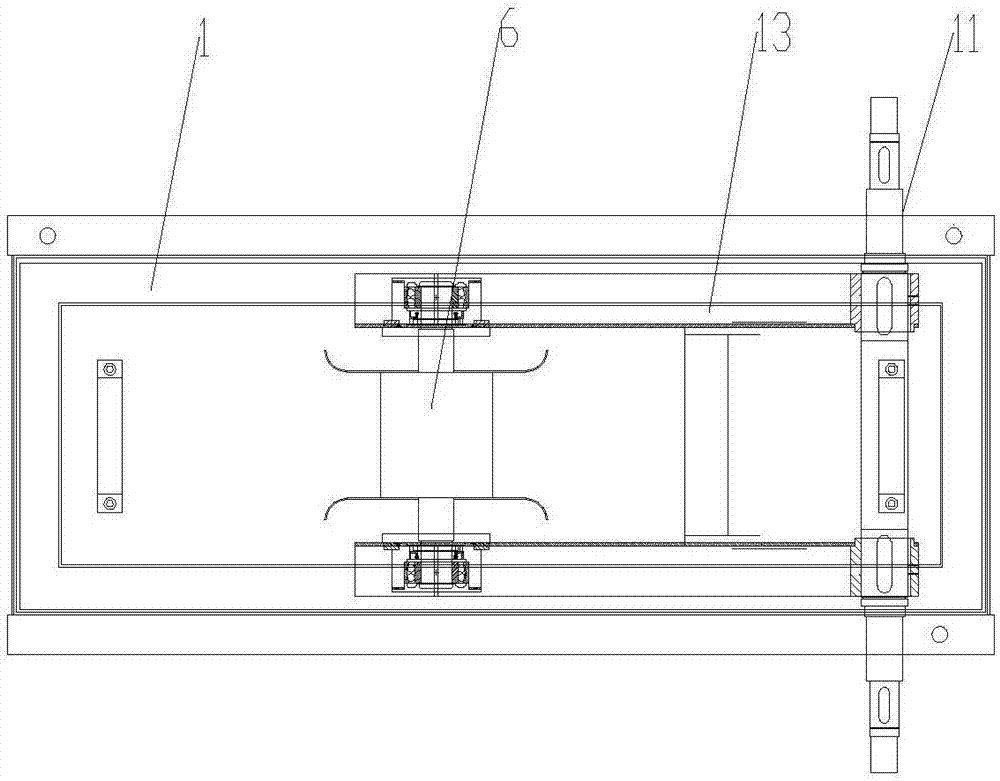

Pad Washer Closed Tension Stand

ActiveCN107142643BReduce lossGuaranteed processing temperatureTextile treatment containersTextile treatment carriersEngineeringMechanical engineering

The invention relates to a tension frame, in particular to a rolling-washing-machine closed tension frame, and belongs to the technical field of rolling washing machine devices. The rolling-washing-machine closed tension frame comprises a box wall plate, a cloth feeding guiding roller, a cloth discharging guiding roller, grooved wheel discs, adjusting air cylinders and swinging arms. A bearing base is fixed on the box wall plate, and a swinging-arm rotating shaft is rotationally connected in the bearing base; the two adjusting air cylinders are hinged to the left side and the right side of the box wall plate, the extending ends of the two adjusting air cylinders are connected with the left end and the right end of the swinging-arm rotating shaft through adjusting arms, the swinging arms are fixedly connected on the swinging-arm rotating shaft, and the front ends of the swinging arms are connected with the grooved wheel discs. According to the rolling-washing-machine closed tension frame, steam losses in device operating are reduced through the closed structure, and the technology temperature of cloth is guaranteed; meanwhile, the tension of the cloth is adjusted through the air-cylinder swinging arms, device operating is more stable and more reliable, operation is convenient, losses of accessories are greatly reduced, the device cost is reduced, and maintenance is more convenient.

Owner:无锡合众印染机械有限公司

Insulation apparatus for glass tank furnace

InactiveCN103387325BEvenly distributedReduced insulation performanceGlass furnace apparatusFiberGlass fiber

Owner:常州循天节能科技有限公司

Built-in direct-discharge type vapor-liquid phase change nozzle combination module

PendingCN113108233ARapid succession exclusionStop lossSpray nozzlesSteam trapsFluid phaseEngineering

The invention provides a built-in direct-discharge type vapor-liquid phase change nozzle combined module. The built-in direct-discharge type vapor-liquid phase change nozzle combined module comprises a cylindrical module body, wherein an equal-diameter direct-discharge through hole and a plurality of nozzle through holes arranged in the circumferential direction are formed in the module body; and the nozzle through holed sequentially comprise bowl-shaped grooves communicated with one another, throat measuring holes with different diameters and a liquid outlet spraying flow channel from top to bottom in the vertical direction. According to the built-in direct-discharge type vapor-liquid phase change nozzle combined module, an adjusting handle can be rotated at any time to adjust the diameter of a nozzle so as to change the condensate displacement change of an energy saver according to the change of the condensate load of steam equipment, so that the condensate displacement change is reasonably matched with the equipment working condition and the actual condensate load all the time, condensate is timely discharged, and meanwhile, steam loss can be effectively prevented, and the process temperature and the process pressure are ensured.

Owner:凯恩(天津)节能环保科技有限公司

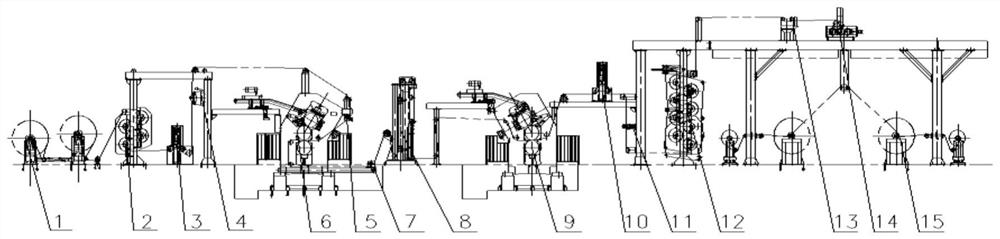

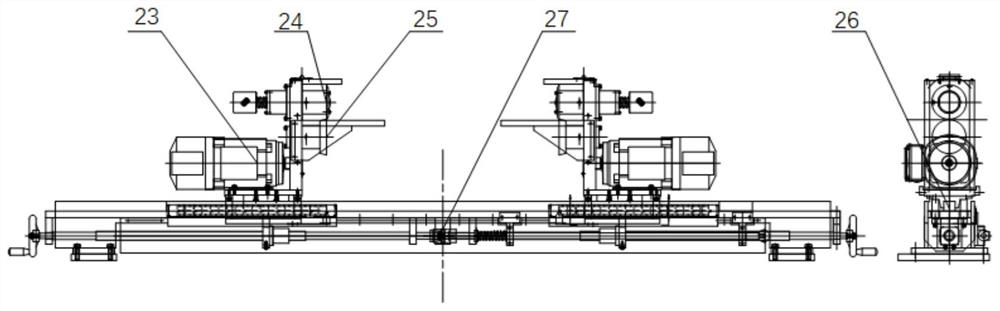

One-time double-sided frictioning calendering line

PendingCN114311478AImprove glue qualityImprove abrasion resistance and adhesionProcess engineeringLeather belt

The invention discloses a one-time double-sided rubberizing calendering line, and belongs to the technical field of rubber calendering. According to the invention, two hydraulic distance-adjusting three-roller calenders and a group of linkage devices are adopted, so that a canvas one-time double-sided frictioning process is realized, and different technological formula requirements of double-sided frictioning are met; the two hydraulic distance-adjusting three-roller calenders are adopted, after the first surface is rubberized, the process temperature is guaranteed, and the second surface is subjected to high-adhesion rubberizing when the rubberized fabric is not cooled, so that the canvas rubberizing quality is improved, and the wear resistance and the adhesive force of the belt are effectively improved; a hydraulic tension adjusting device is adopted, so that the tension of canvas between the two hydraulic distance-adjusting three-roller calenders is stable, and the frictioning quality is ensured; according to the invention, a traditional dip coating process in the triangular belt industry can be replaced, a one-time double-sided frictioning process is realized, and different process formulas are met; the problems that three adhesive tape wrapping cloth layers are high in production cost and flammable, explosive and safe in production are solved, meanwhile, the frictioning quality is improved, and the production efficiency is improved.

Owner:大连橡胶塑料机械有限公司

Low temperature vacuum drier

ActiveCN101046351BReduce the temperatureQuality improvementDrying solid materials without heatDrying machines with local agitationEngineeringVacuum pump

The low temperature vacuum drier for processing leather includes one cover on the machine frame, at least one layer of working board with heating element and vacuumizing ports and hoisted by means of oil cylinder onto the machine frame, one liquid collecting tank connected to the liquid draining grooves and connected to the vacuum pump, at least two safety devices on the uprights of the machine frame, one condensation system connected to the working board, one sealing cover below the working board, one cooling pipeline around the working board, and vacuum pump comprising oil circulating vacuum pump and Roots vacuum pump. The present invention has high vacuumizing capacity, lowered operation temperature, no damage on the leather tissue and raised quality of dried leather.

Owner:NANTONG SIRUI ENG

Rolling-washing-machine closed tension frame

ActiveCN107142643AReduce lossGuaranteed processing temperatureTextile treatment containersTextile treatment carriersEngineeringWall plate

The invention relates to a tension frame, in particular to a rolling-washing-machine closed tension frame, and belongs to the technical field of rolling washing machine devices. The rolling-washing-machine closed tension frame comprises a box wall plate, a cloth feeding guiding roller, a cloth discharging guiding roller, grooved wheel discs, adjusting air cylinders and swinging arms. A bearing base is fixed on the box wall plate, and a swinging-arm rotating shaft is rotationally connected in the bearing base; the two adjusting air cylinders are hinged to the left side and the right side of the box wall plate, the extending ends of the two adjusting air cylinders are connected with the left end and the right end of the swinging-arm rotating shaft through adjusting arms, the swinging arms are fixedly connected on the swinging-arm rotating shaft, and the front ends of the swinging arms are connected with the grooved wheel discs. According to the rolling-washing-machine closed tension frame, steam losses in device operating are reduced through the closed structure, and the technology temperature of cloth is guaranteed; meanwhile, the tension of the cloth is adjusted through the air-cylinder swinging arms, device operating is more stable and more reliable, operation is convenient, losses of accessories are greatly reduced, the device cost is reduced, and maintenance is more convenient.

Owner:无锡合众印染机械有限公司

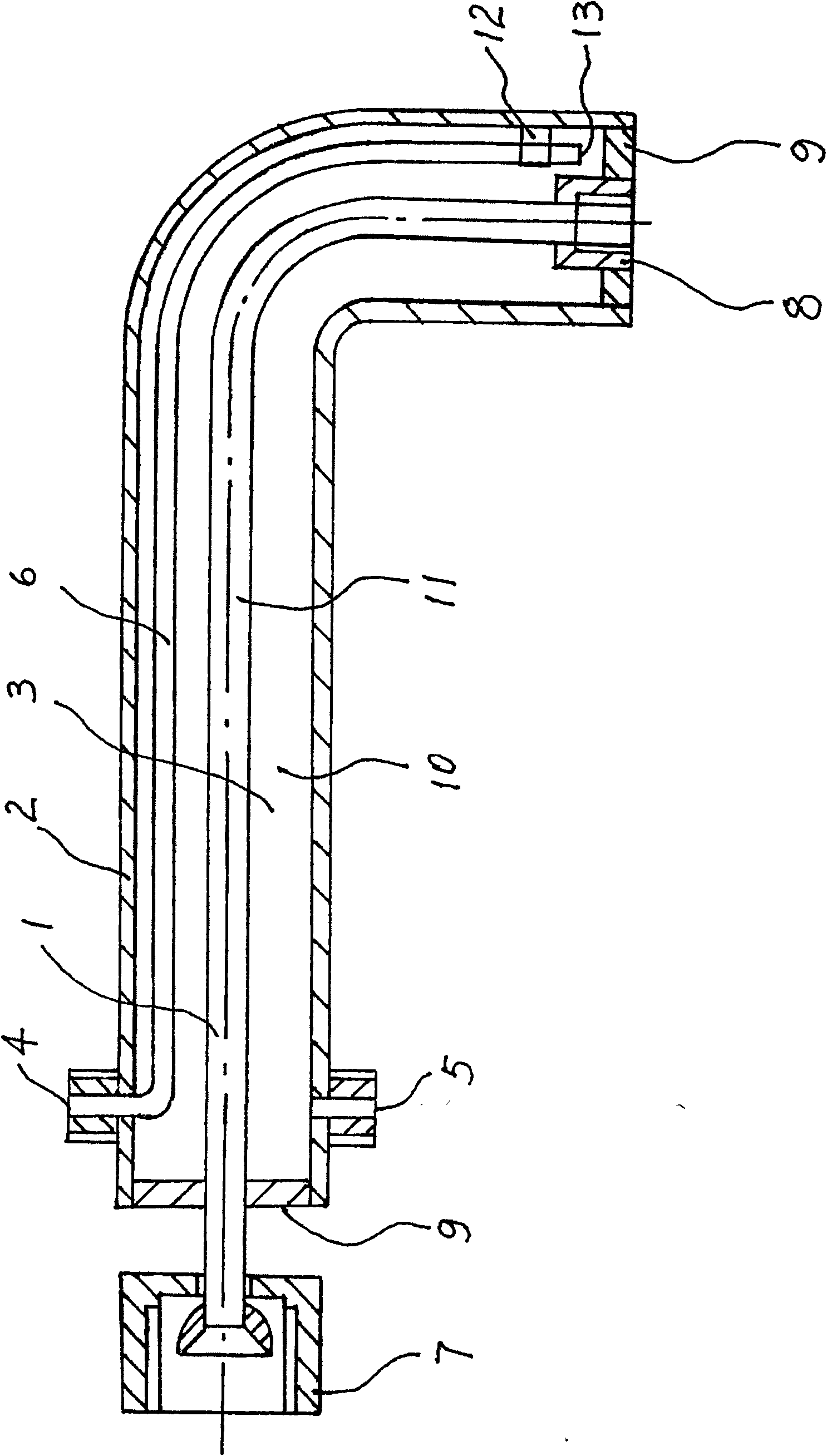

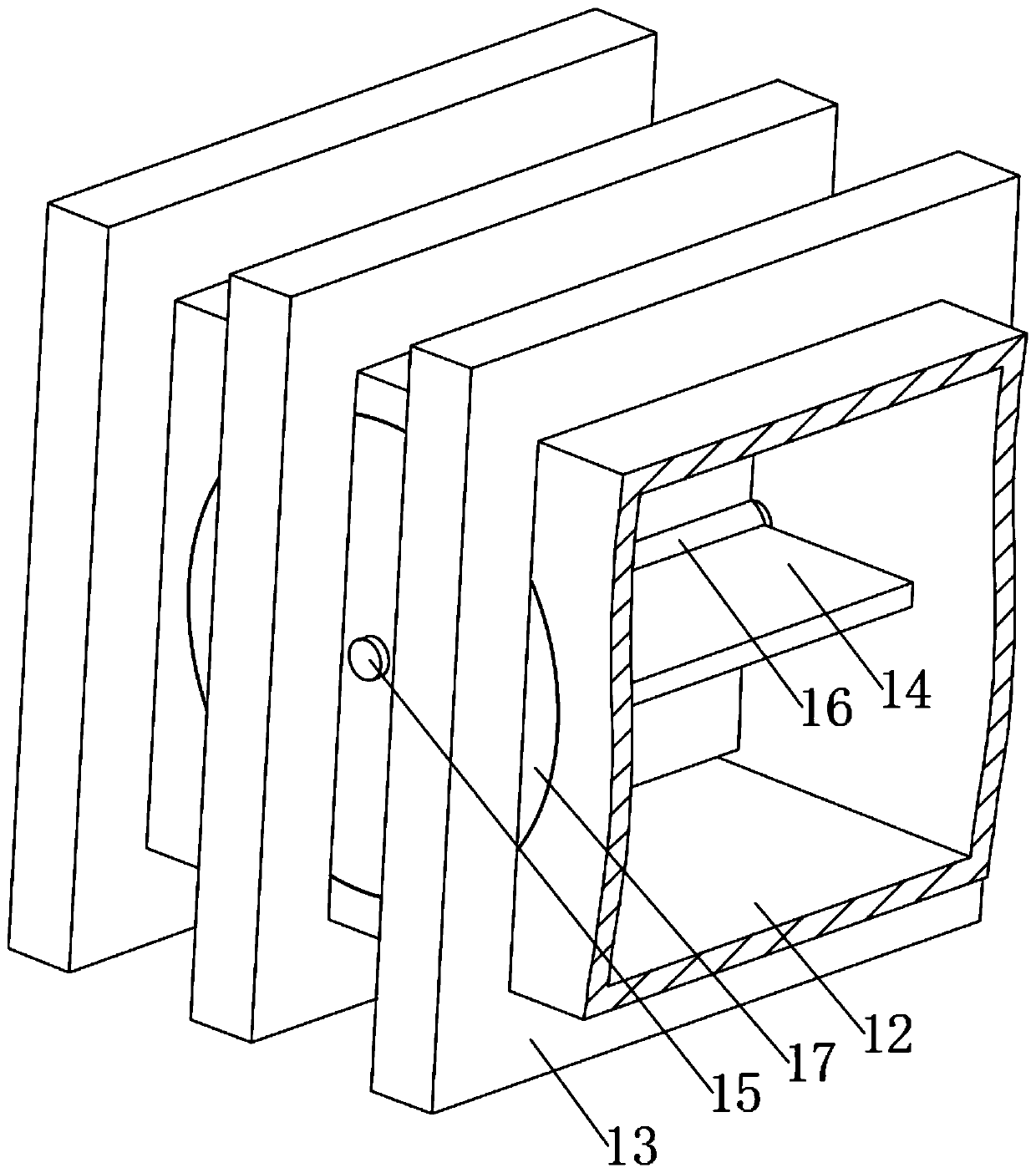

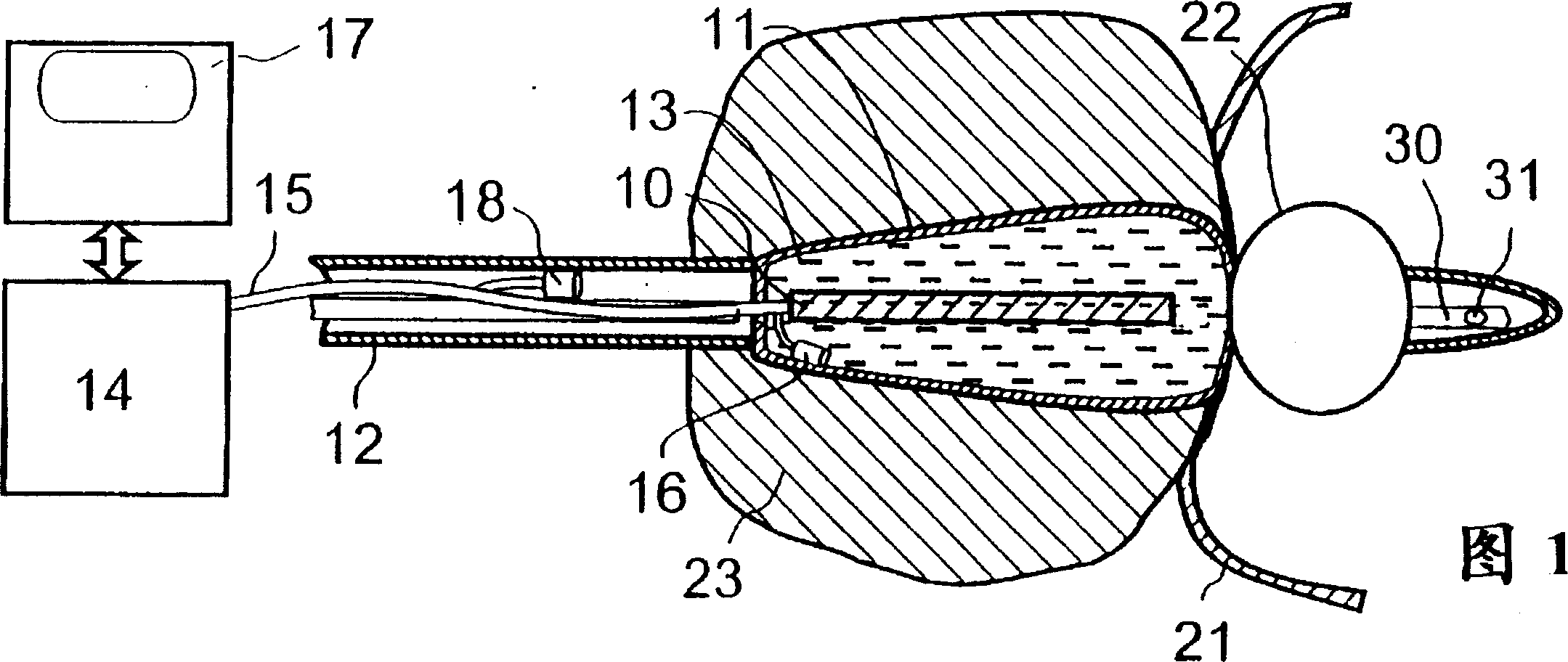

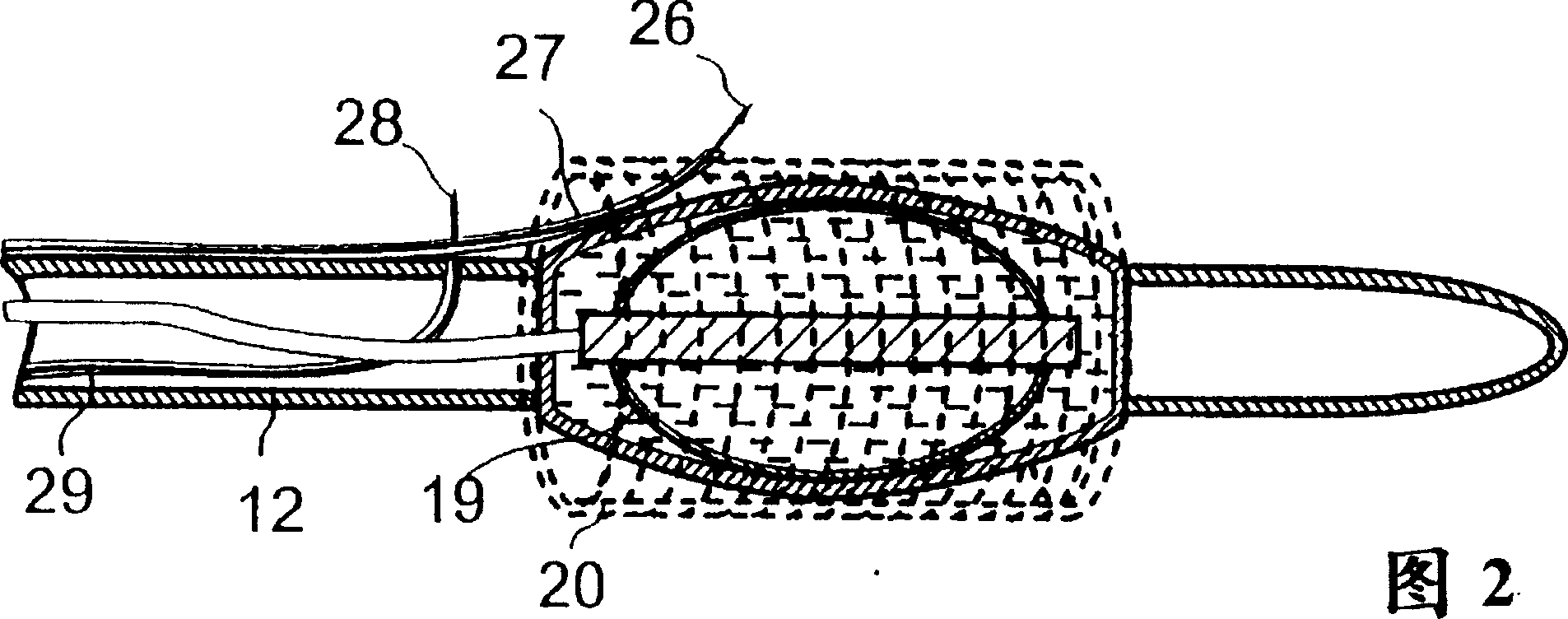

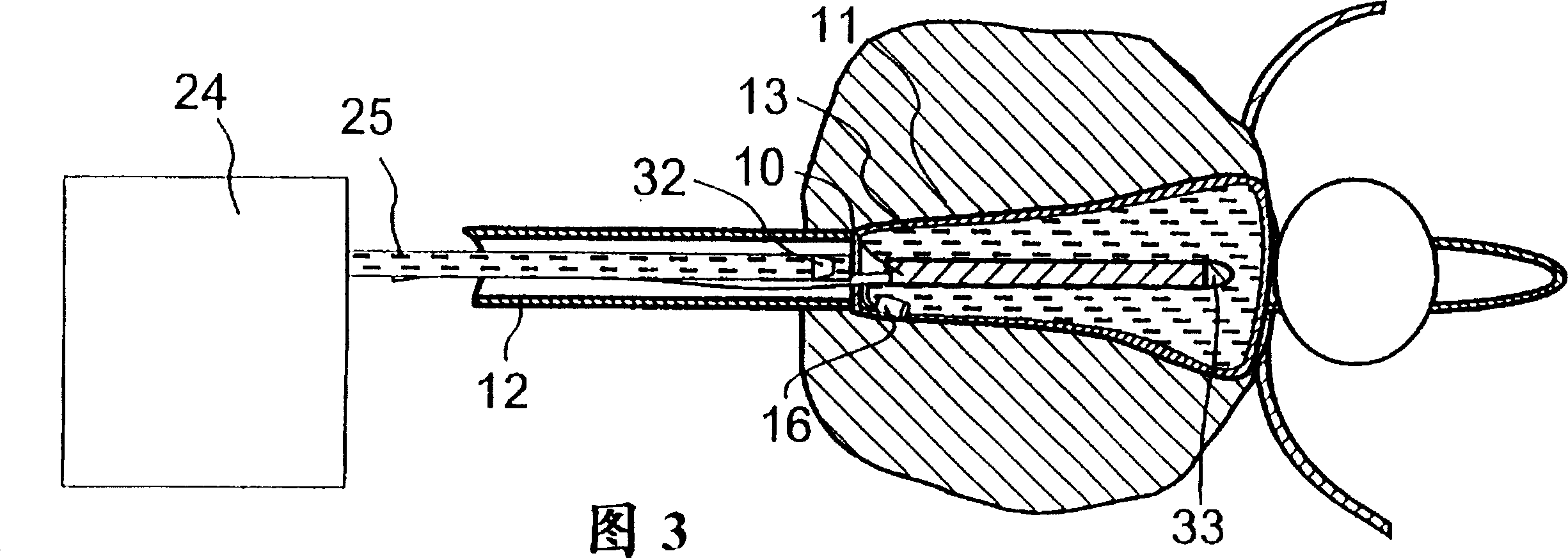

Device for local heat treatment of tissue

InactiveCN1158975CGuaranteed processing temperatureStentsBalloon catheterEnergy supplyConvective heating

A device for heat treatment of body tissue, comprising a catheter (12), which is insertable in the body and is equipped with an expandable fluid receptacle (11). The fluid receptacle (11) contains heating means (10) for convective heating of fluid contained in the receptacle (11) and, thus, heating of the tissue in an area of treatment located in the environment surrounding the fluid receptacle (11). The heating device (10) is connected to an energy supply unit (14) located outside of the body.

Owner:LUND INSTR AB

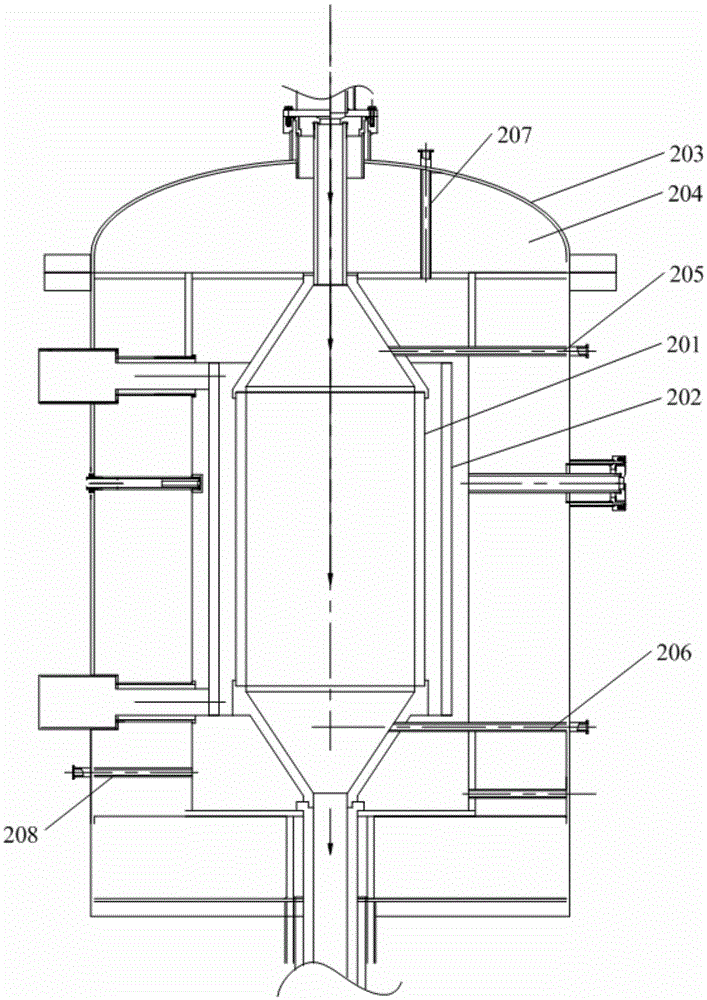

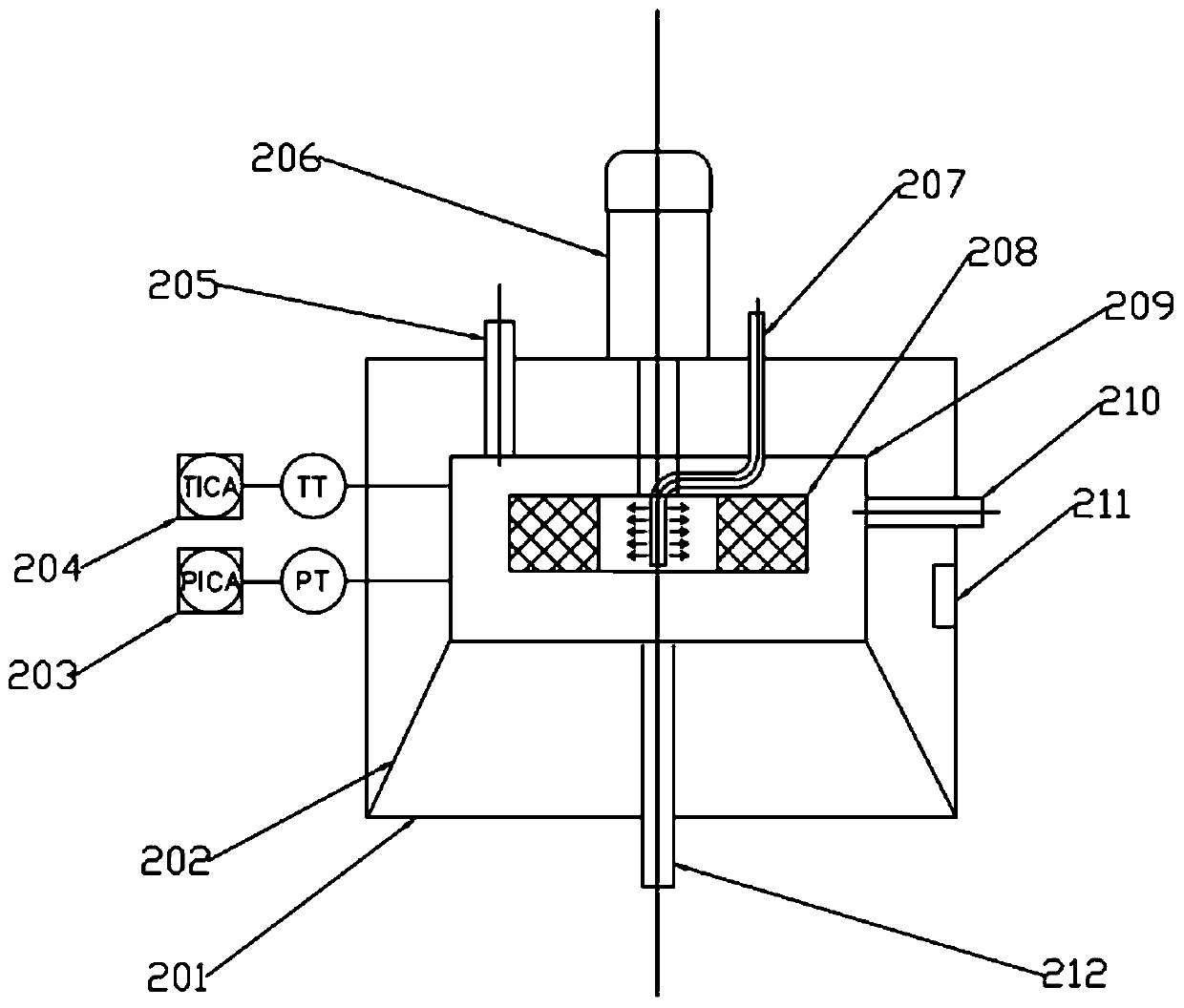

A microwave coupling high gravity rotating bed device and its application

ActiveCN107224958BAvoid destructionDoes not affect normal feedEnergy based chemical/physical/physico-chemical processesChemical/physical/physico-chemical moving reactorsMicrowaveReaction rate

The invention discloses a microwave-coupled supergravity revolving bed device and application thereof. The device comprises a microwave generating device, wherein the microwave generating device can feed emitted microwaves inside a closed chamber consisting of an end cover and a shell body, and the microwaves act on reactants inside the closed chamber so as to heat the reactants and / or increase reaction rate. According to different feed-in modes, direct feed-in devices and indirect feed-in devices are present. According to the device disclosed by the invention, the rapid heating of the reactants is achieved by using the auto-heating effect of the microwaves to liquid while a supergravity revolving bed gives full play to the strengthening of mass transfer and mixing, so that the process temperature is guaranteed; and by using an electromagnetic effect of the microwaves, the reaction rate of a slow reaction process. The supergravity revolving bed can be filled with different types of fillers and can be applied to liquid-containing systems of different types such as liquid-liquid, gas-liquid, liquid-solid and gas-liquid-solid. The device has the advantages of small investment, low energy consumption, high heating speed and the like.

Owner:BEIJING UNIV OF CHEM TECH

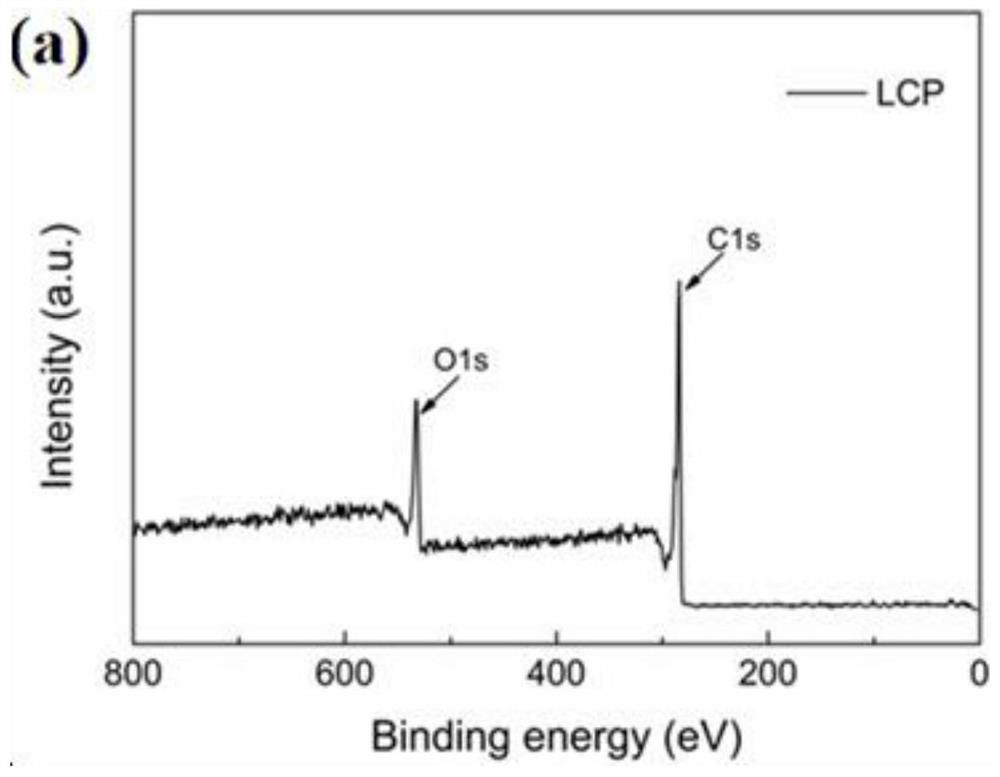

Liquid crystal polymer, preparation method thereof and liquid crystal polymer film

ActiveCN113527647AImprove mechanical propertiesReduce processing temperatureLiquid crystal compositionsPolymer scienceChain structure

The invention provides a liquid crystal polymer, a preparation method thereof and a liquid crystal polymer film. The liquid crystal polymer provided by the invention comprises three repetitive units as shown in formulas I-III, anthryl is introduced into a liquid crystal polymer structure, and meanwhile, a flexible chain structure is introduced to a part of anthracene rings and is matched with a phenyl structure; the design can break the regularity of the main chain structure of the liquid crystal polymer, reduce the forming temperature of the liquid crystal polymer in the processing process, and solve the problems of serious mechanical property differentiation, poor batch stability and the like of the formed product without influencing other performance indexes.

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com