Preparation method of high-alloy centrifugal roller

A roll and alloy technology, applied in manufacturing tools, heat treatment equipment, furnace types, etc., can solve the problems of complex production process, high equipment requirements, low production efficiency, etc., achieve simple production process, low equipment requirements, and improve production efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0019] A method for preparing a high-alloy centrifugal roll. The high-alloy centrifugal roll includes a working layer and a core, wherein the material of the working layer is high-alloy hypereutectoid steel, and the chemical components and the mass percentages of each component are C≥ 1.0%, Cr+Ni+Mo+V+W≥12%.

[0020] Pour the molten steel in the working layer of the prepared roll into the centrifugal casting machine, fill in the molten steel in the core after a period of time, and then transfer it to the heat preservation pit, below the solidus temperature of the working layer material and above the temperature of the pearlite transformation zone Carry out temperature control and slow cooling so that the average cooling rate is ≤20°C / h; when the temperature drops to the temperature of the pearlite transformation zone of the working layer material, perform rapid cooling treatment, and the cooling rate in the temperature of the pearlite transformation zone reaches the temperature...

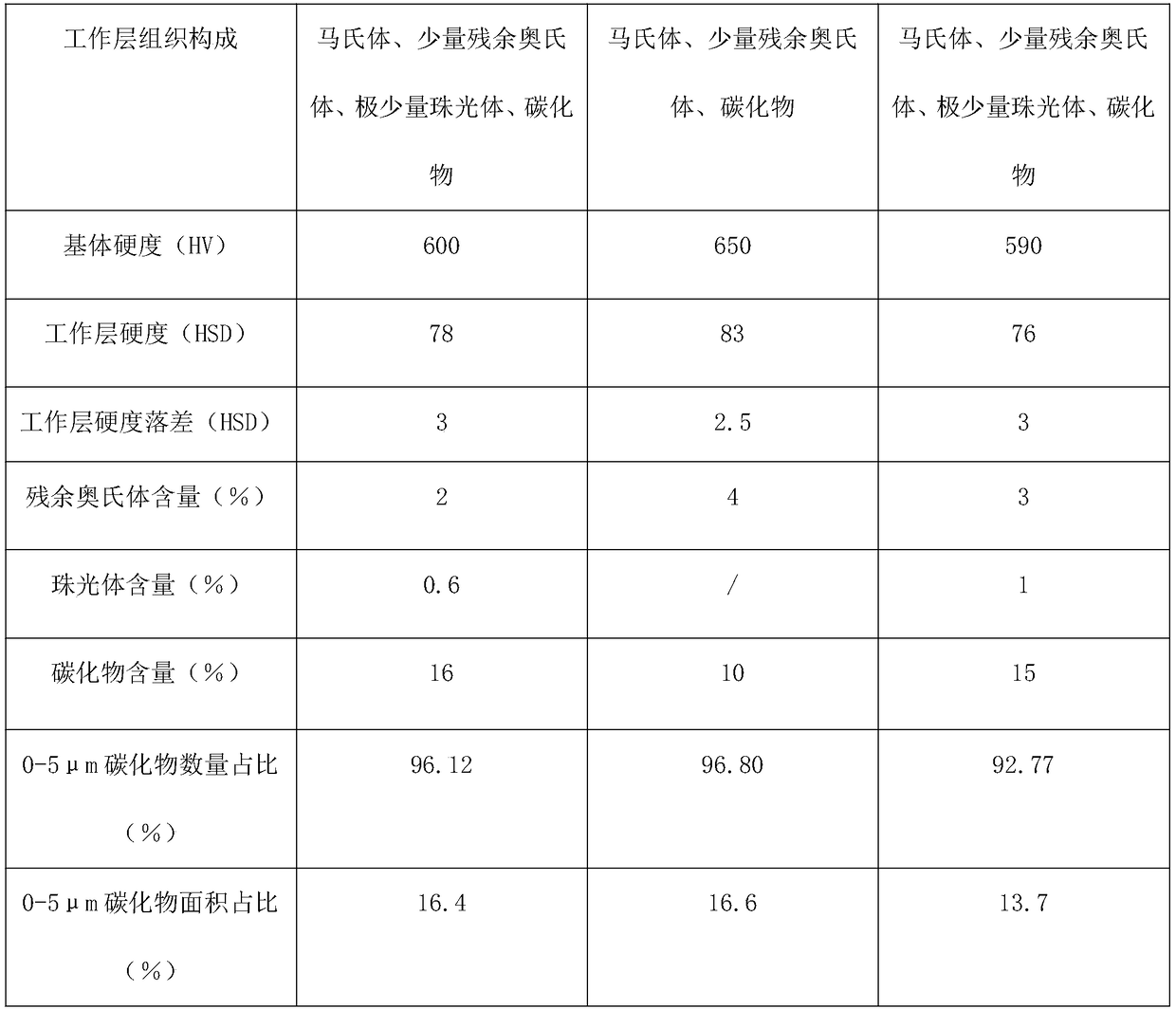

Embodiment 1

[0024] The invention discloses a preparation method of a high-alloy centrifugal roll. The high-alloy centrifugal roll includes a working layer and a core. The diameter of the roll body is 1200mm, the working layer is 50mm (radius), and the hardness requirement is 72-78HSD. The C content of the working layer of the design roll is 1.9-2.1%, and the Cr+Ni+Mo+V+W content is 18.5%.

[0025] Pour the molten steel in the working layer of the prepared roll into the centrifugal casting machine, fill in the molten steel in the core after a period of time, and test it with a thermal dilatometer. It is measured that the solidus line of the working layer material is about 1140 ° C, and the pearlite interval is about 740~620℃, the critical cooling rate is required to be 0.01℃ / s. Transfer the rolls to the heat preservation pit, and add a protective cover outside the rolls, so that the working rolls can be cooled slowly in the temperature range of 1140-740 ° C, so that the average cooling rat...

Embodiment 2

[0028] A preparation method of a high-alloy centrifugal roll. The high-alloy centrifugal roll includes a working layer and a core. The diameter of the roll body is 760mm, the working layer uses 40mm (radius), and the hardness requirement is 78-85HSD. The C content of the working layer of the design roll is 1.4-1.7%, and the Cr+Ni+Mo+V+W content is 13.5%.

[0029]Pour the molten steel in the working layer of the prepared roll into the centrifugal casting machine, fill in the molten steel in the core after a period of time, and test it with a thermal dilatometer. It is measured that the solidus of the working layer material is about 1150°C, and the pearlite interval is about 720~640℃, the critical cooling rate is required to be 0.02℃ / s. Transfer the rolls to the heat preservation pit, and add a protective cover outside the rolls, so that the working rolls can be cooled slowly in the temperature range of 1150-720 ° C, so that the average cooling rate is ≤ 20 ° C / h, after 16 hou...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com