A microwave coupling high gravity rotating bed device and its application

A technology of a supergravity rotating bed and a microwave generating device, which is applied in the field of supergravity, can solve the problems of rapid temperature rise of difficult fluids, long-term heat preservation, etc., and achieves the effects of isolating high temperature and high pressure, high thermal efficiency, and ensuring process temperature.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

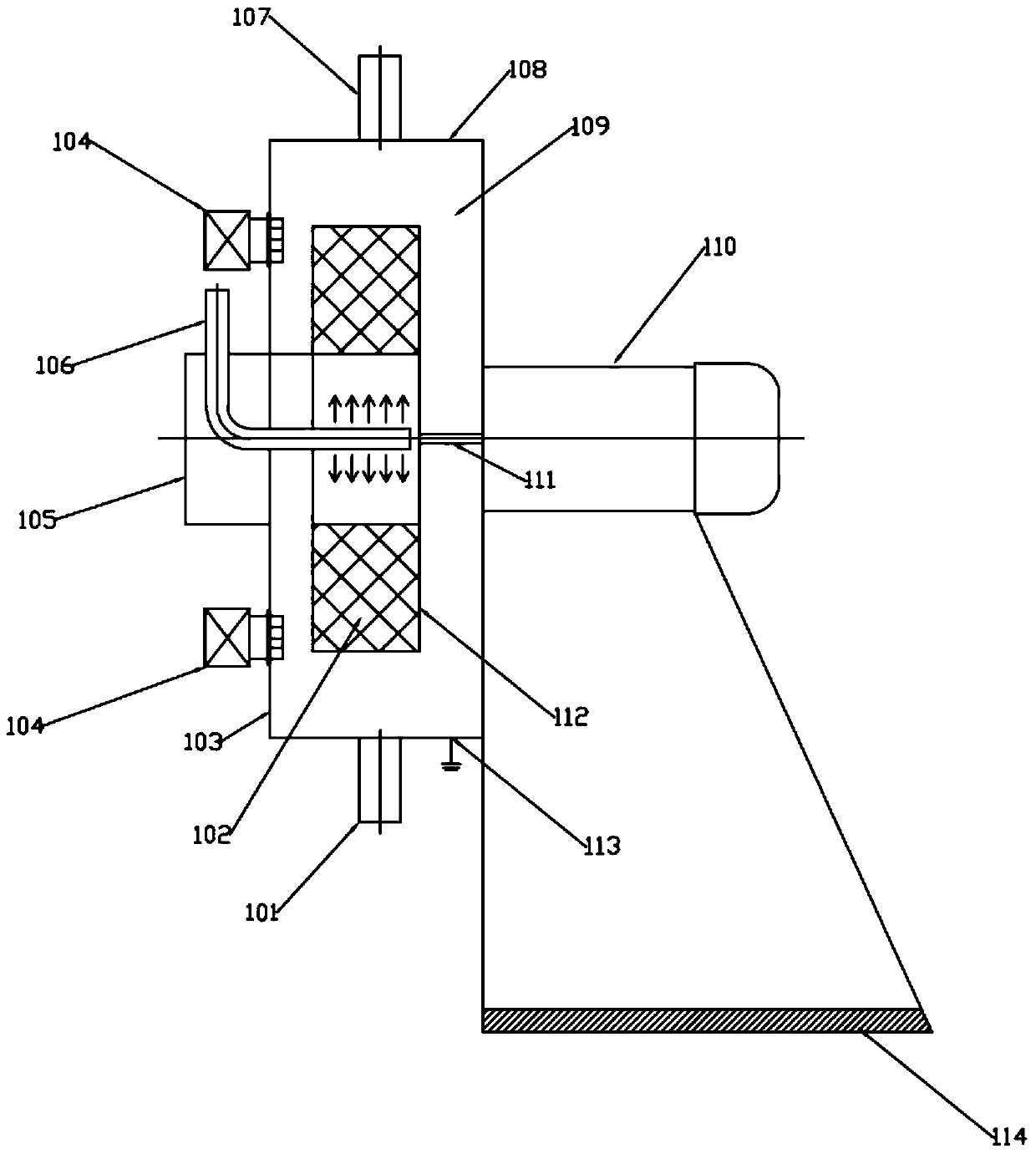

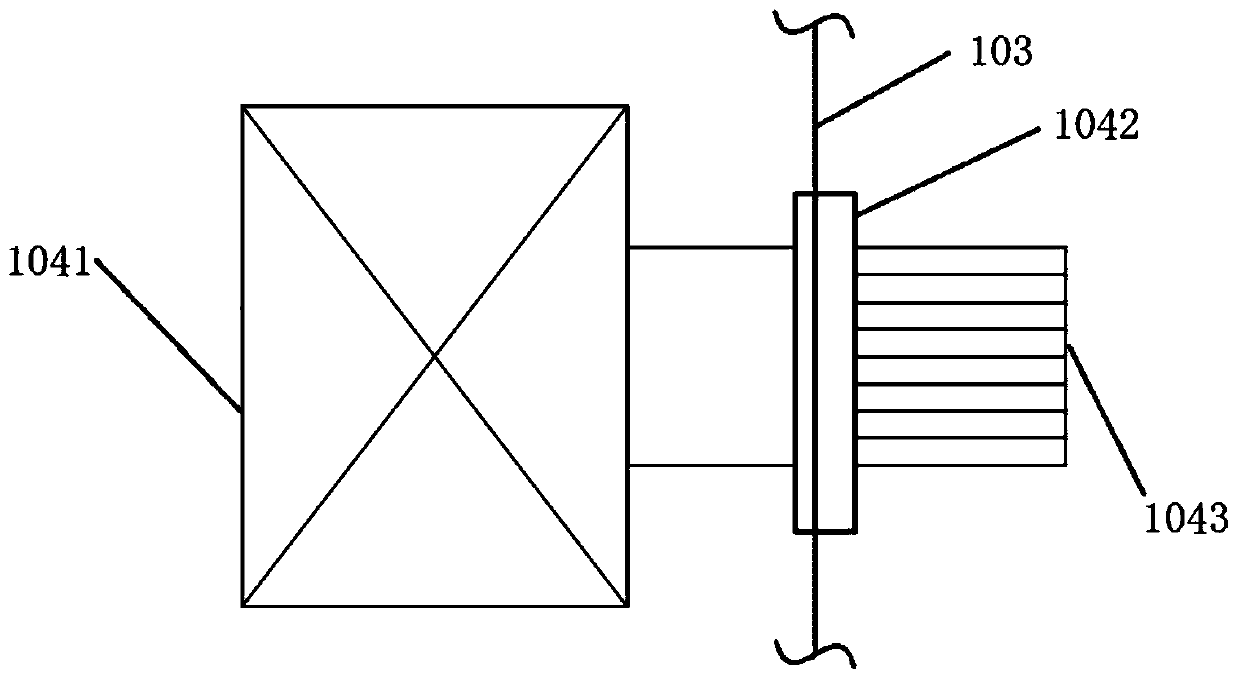

[0043] see figure 1As shown, a direct microwave coupling high-gravity rotating bed includes a housing 108, an end cover 103, a rotor 112 and a transmission device 110; the housing 108 and the end cover 103 form a closed cavity 109, in which A rotor 112 is arranged in the body 109, and a filler 102 is arranged on the rotor 112; the rotor 112 is connected with the transmission device 110 outside the airtight cavity through the rotating shaft 111; the gas inlet 107 and the liquid outlet 101 are arranged on the casing 108; The end cover is provided with a gas outlet 105 and a liquid input distributor 106, and the liquid input distributor penetrates from the end cover and extends into the central cavity of the rotor, and is close to the inner edge of the innermost packing; at the end of the supergravity rotating bed There is a microwave generating device 104 on the cover, and a plurality of microwave generating devices 104 are evenly distributed on one side of the end cover; and th...

Embodiment 2

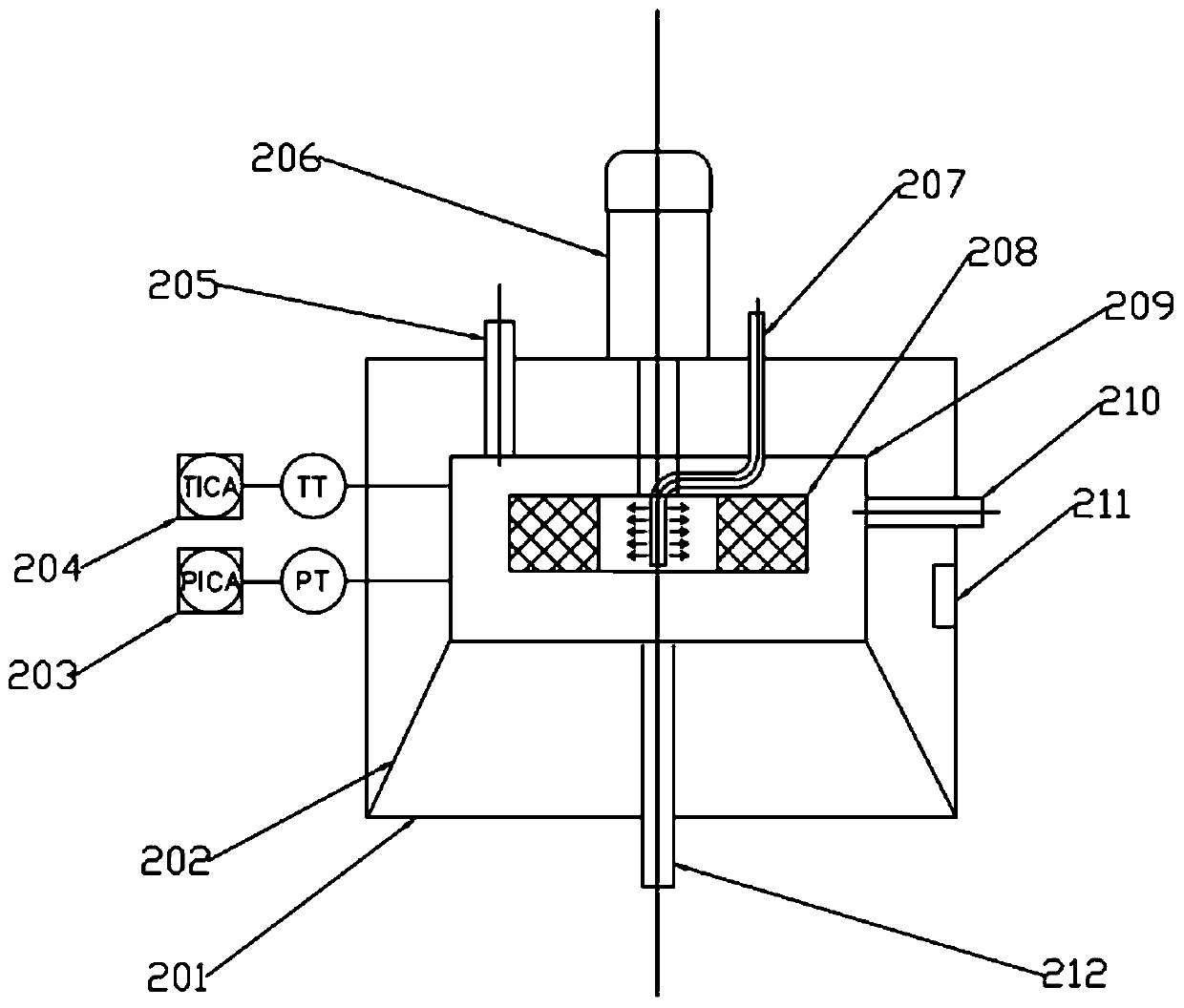

[0052] See image 3 As shown, an indirect microwave-coupled high-gravity rotating bed device includes a microwave generating device and a high-gravity rotating bed reaction device, wherein the microwave generating device includes a microwave resonant cavity 201 , a device support frame 202 and a microwave generator 211 . The microwave resonant cavity 201 is covered on the outer surface of the rotating bed device shell to form a second cavity, which is fixed with the rotating bed device through the device support frame 202 ; the microwave generator 211 is located on the inner wall of the microwave resonating cavity 201 . The high-gravity rotating bed reaction device includes a ceramic shell 209, a rotor 208 and a transmission device 206, and the ceramic shell forms a closed cavity. On the supergravity reaction device, there are liquid inlet 207, liquid outlet 212; gas inlet 210, gas outlet 205, and the motor is used to drive the packing to rotate. The microwave-coupled high-gr...

Embodiment 3

[0054] see Figure 4 As shown, a liquid-liquid reaction system device 300 comprising the ultrasonically coupled high-gravity rotating bed described in Embodiment 1 includes a microwave-coupled high-gravity rotating bed 301, with symmetrically distributed microwaves on the same side of the end cover of the high-gravity rotating bed The generator, the rotor is filled with integral silicon carbide, the liquid input distributor 302, the pump 303, the feed tank 304, and the product tank 305. The above-mentioned devices are connected by silicone tubes, see Figure 4 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com