Melt liquid raising device for multi-station parallel-connection pressurizing cast device

A pressurized casting and melt technology, applied in the field of liquid lifting system, can solve the problems of affecting casting production efficiency, casting quality, reducing the temperature of aluminum melt in the liquid rising pipe, and castings cannot be effectively fed, so as to achieve popularization and application High value, safe and reliable use process, simple installation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

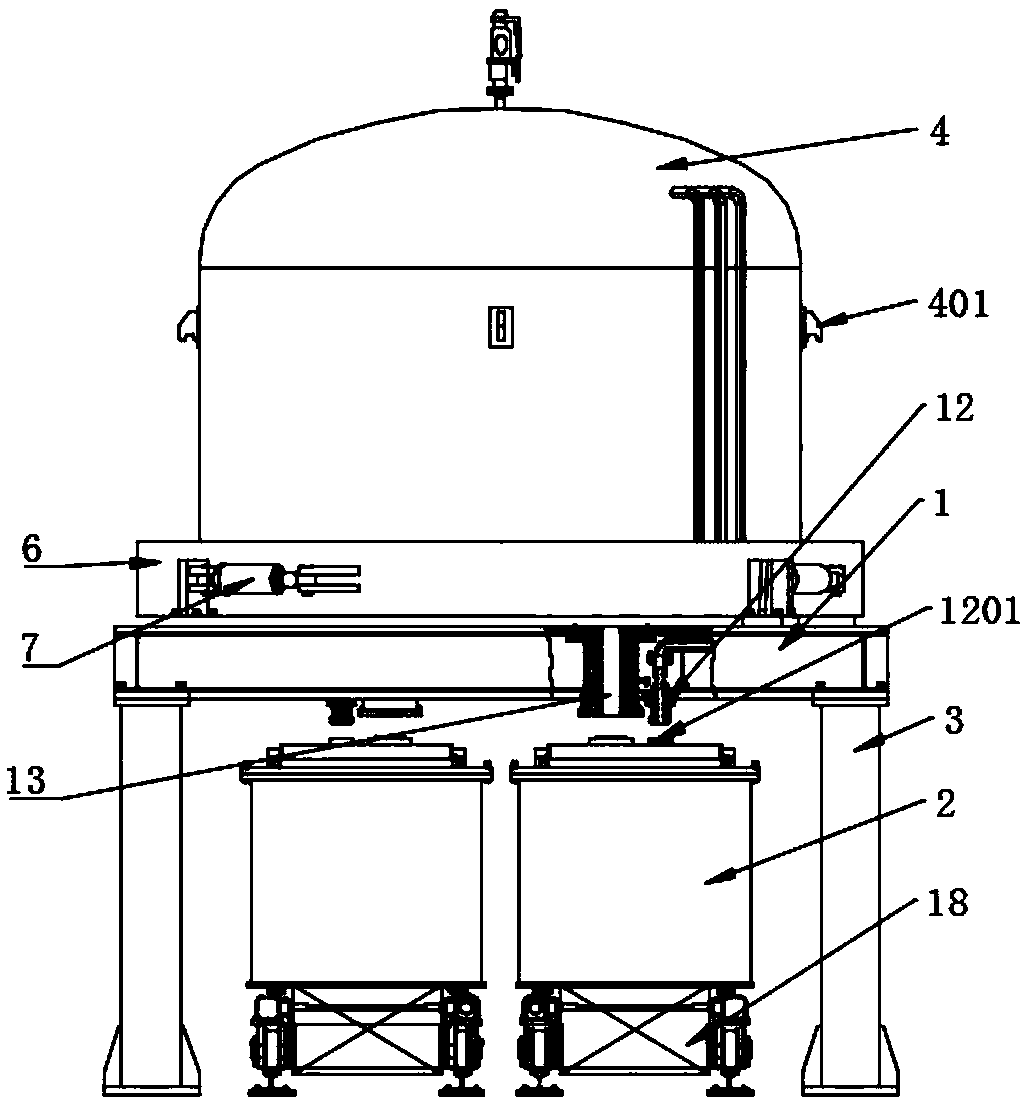

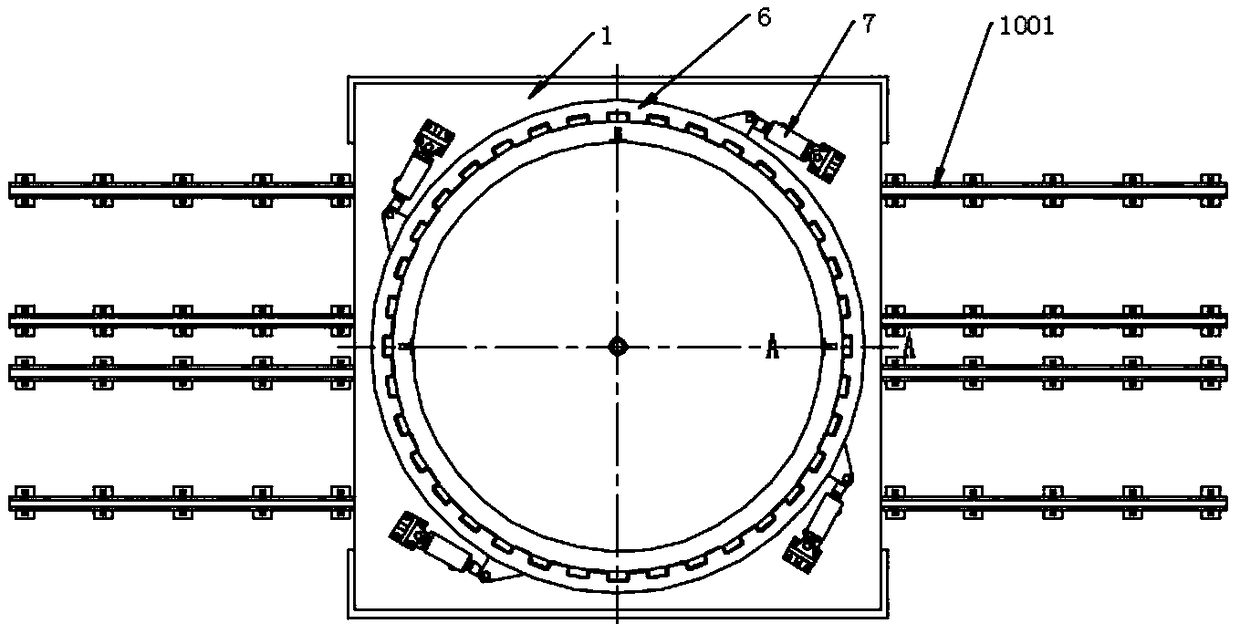

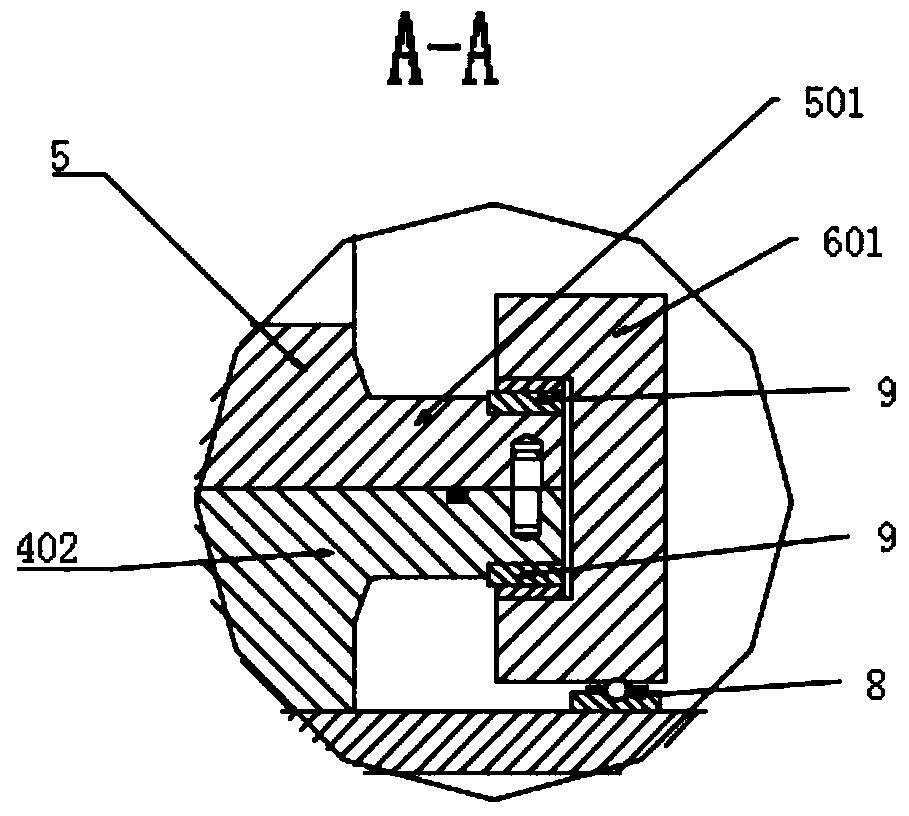

[0029] Embodiment 1: as Figure 1-9 As shown, this embodiment provides a melt lifting device for a multi-position parallel pressure casting device, wherein the multi-position parallel pressure casting device means that the casting device has multiple The liquid filling port and the liquid riser form a parallel pressurization of multiple positions through a plurality of liquid risers.

[0030] This embodiment provides a multi-position parallel pressure casting device for large aluminum alloy castings, which is suitable for manufacturing large and complex castings in the fields of aerospace, weapons, ships, automobiles, electronics, etc., especially large and complex aluminum alloy frames, Castings such as plate shapes and cabins can solve the problems of turbulent flow, cold shut, insufficient pouring, excessive pinhole and porosity, serious oxidation inclusions and other problems existing in the manufacture of these large and complex castings, and improve the yield of castings...

Embodiment 2

[0066] Embodiment 2: According to the multi-position parallel pressure casting device disclosed in Embodiment 1 and its melt liquid raising device, control system and method, this embodiment takes a large corrosion-resistant aluminum-magnesium alloy box member as the application object, and provides melting The operation steps of the body lifting process, the specific outline size of the large corrosion-resistant aluminum-magnesium alloy box member: 2440mm×2070mm×1450mm, the main body wall thickness is 20.0mm, the weight is 1642kg, and there are many internal reinforcement ribs, thick and large bosses and other structures, Material: ZL305.

[0067] The operation steps of the molten aluminum rising liquid process are carried out as follows:

[0068] (1) First melt 2500kg of aluminum melt in the melting furnace for use, and use the furnace body walking mechanism to withdraw the 4 holding furnaces from the multi-position parallel casting machine, and paint 5mm of insulating paint...

Embodiment 3

[0074] Embodiment 3: According to the multi-position parallel pressure casting device disclosed in Embodiment 1 and its melt raising device, control system and method, this embodiment takes a large-scale high-performance aluminum-copper alloy plate-shaped component as the application object, and provides melting The operation steps of the body lifting process, the specific outline size of the large high-performance aluminum-copper alloy plate-shaped component: 2430mm×2160mm×180mm, the main body wall thickness is 18.0mm, and the weight is 625kg. There are many internal reinforcement ribs and thick bosses. Typical plate shaped structure, material: ZL205A.

[0075] The operation steps of the molten aluminum rising liquid process are carried out as follows:

[0076] 1) First melt 1600kg of aluminum melt in the melting furnace for use, use the furnace body walking mechanism to withdraw the 4 holding furnaces from the multi-position parallel casting machine, paint 5mm heat preservat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal resistance | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com