Low temperature vacuum drier

A technology of low-temperature vacuum drying and vacuum pump, which is applied in local agitation dryers, static material dryers, dryers, etc. It can solve problems such as shortening the service life of vacuum pumps, increasing the gap between the impeller and the pump body, and affecting the quality of leather. Achieve superior performance, improve sealing performance, and reduce energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

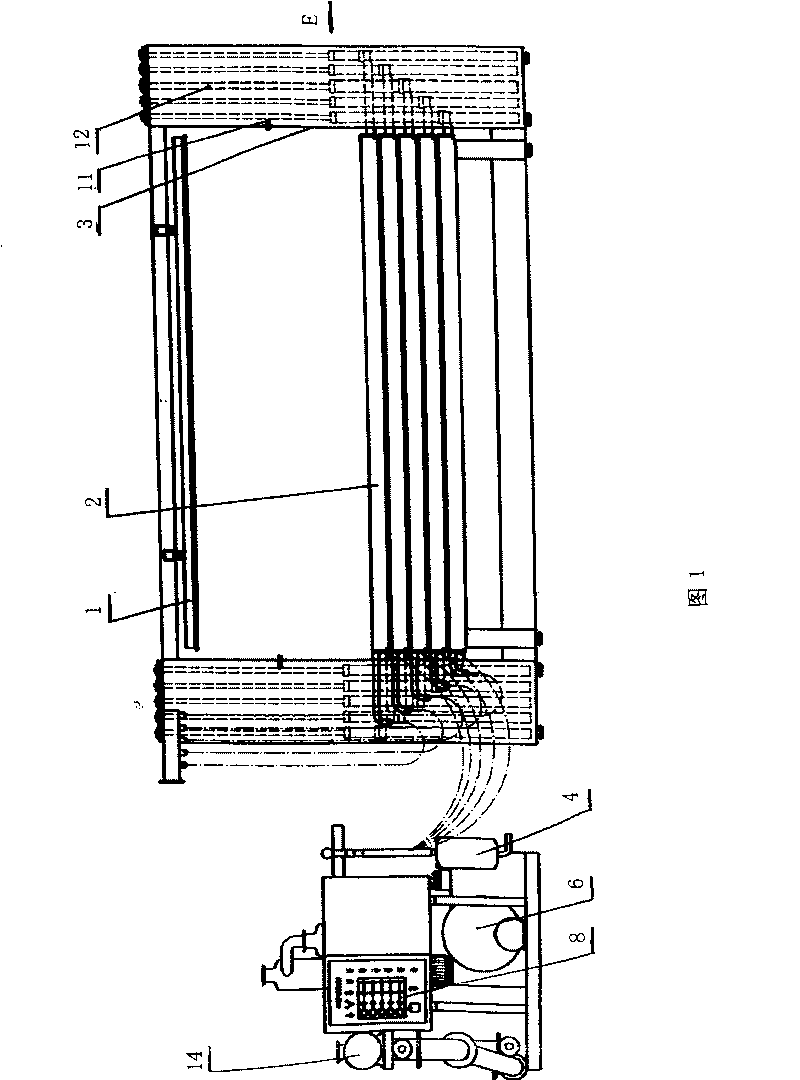

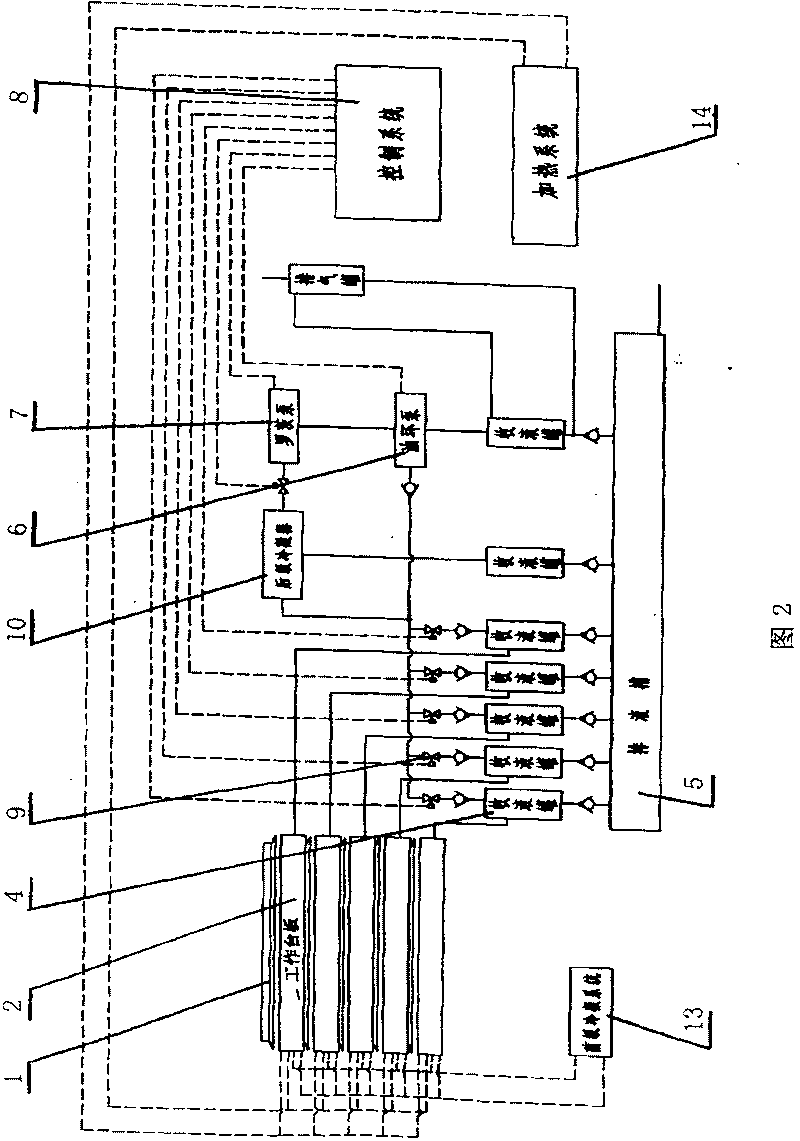

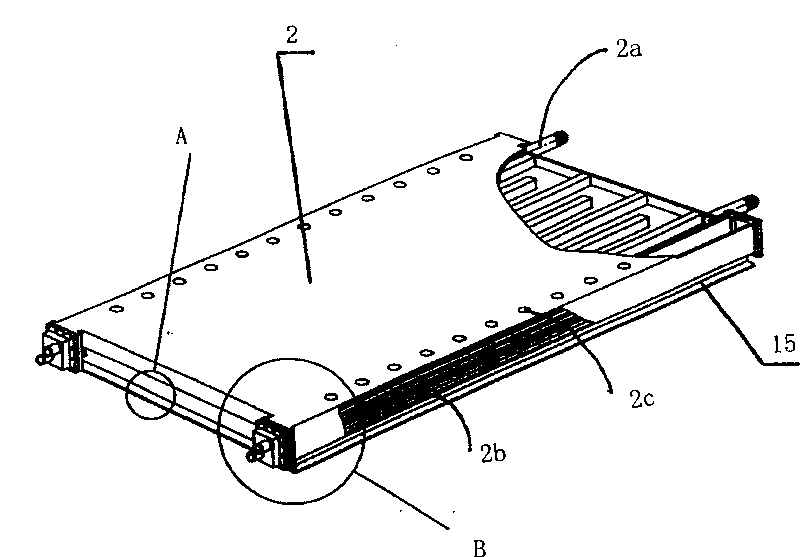

[0017] Refer to attached figure 1 , attached figure 2 , a low-temperature vacuum dryer of the present invention includes a cover 1, a worktable 2, a frame 3, a liquid receiving tank 4, a liquid drainage tank 5, a vacuum pump I 6, a vacuum pump II 7, a control system 8, and a control valve 9 , the rear condenser 10, the safety device 11, the oil cylinder 12, the front condensation system 13, the cover 1 is sealed with the worktable 2 on the top floor; The workbench 2 is designed to have five layers, the cover 1 is hoisted on the frame 3, and the workbench 2 of each layer is hoisted on the frame 3 through the oil cylinder 12; the workbench 2 is connected with the liquid receiving tank 4, and the workbench The plate 2 is connected with the heating system 14, the liquid outlet of the liquid receiving tank 4 is connected with the liquid discharge tank 5 respectively, the exhaust port of the liquid receiving tank 4 is respectively connected with the vacuum pump I 6, the vacuum pum...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com