Insulation apparatus for glass tank furnace

A heat preservation device and a glass tank kiln technology, applied in glass furnace equipment, glass manufacturing equipment, manufacturing tools, etc., can solve the problems of slender heat conduction path, less solid content, and lower solid heat conduction rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1)

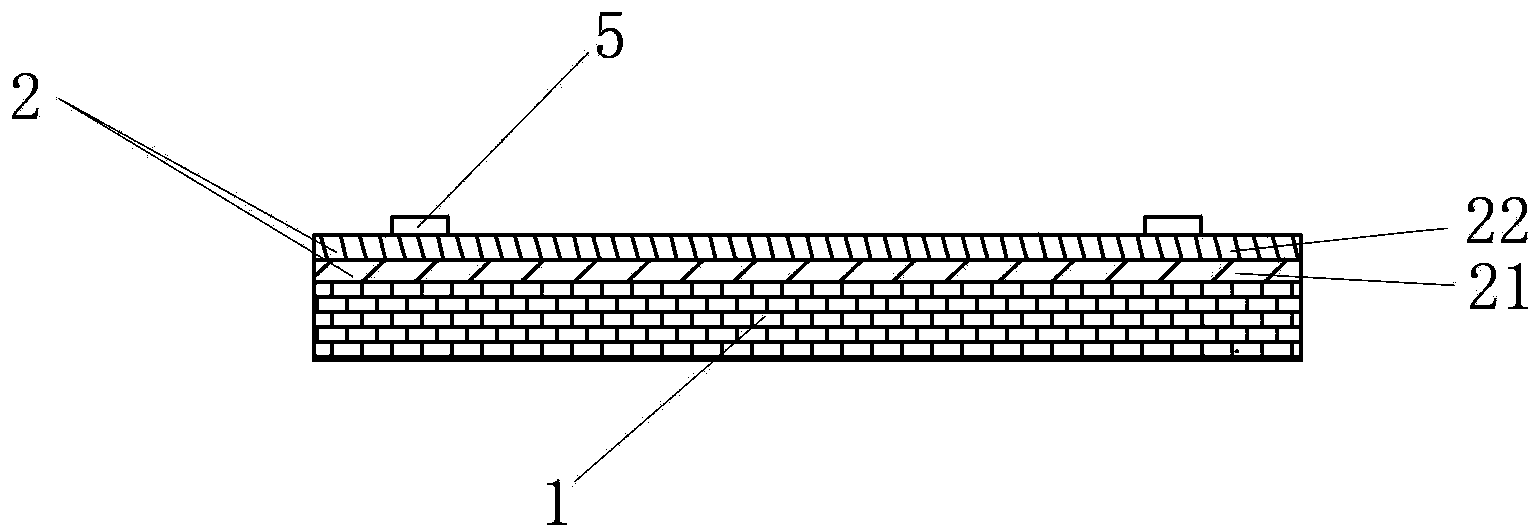

[0051] See figure 1 with figure 2 , The thermal insulation device of the glass tank kiln of this embodiment is the thermal insulation device of the float glass tank kiln, including the thermal insulation composite layer 2 and the fixing member 5 . The thermal insulation composite layer 2 is composed of an aluminum silicate fiber blanket layer 21 and a first airgel thermal insulation blanket layer 22 .

[0052] The aluminum silicate fiber blanket layer 21 and the first airgel thermal insulation blanket layer 22 are sequentially laid and covered on the outer surfaces of all parts of the glass tank kiln where the thermal insulation layer 1 is provided in the order from the inside to the outside, and the fixing member 5 is arranged on the first Outside the airgel thermal insulation blanket layer 22, the thermal insulation composite layer 2 is compacted and compacted on the outer surface of the thermal insulation layer 1 of the glass tank kiln. The thermal insulation layer 1 is ...

Embodiment 2)

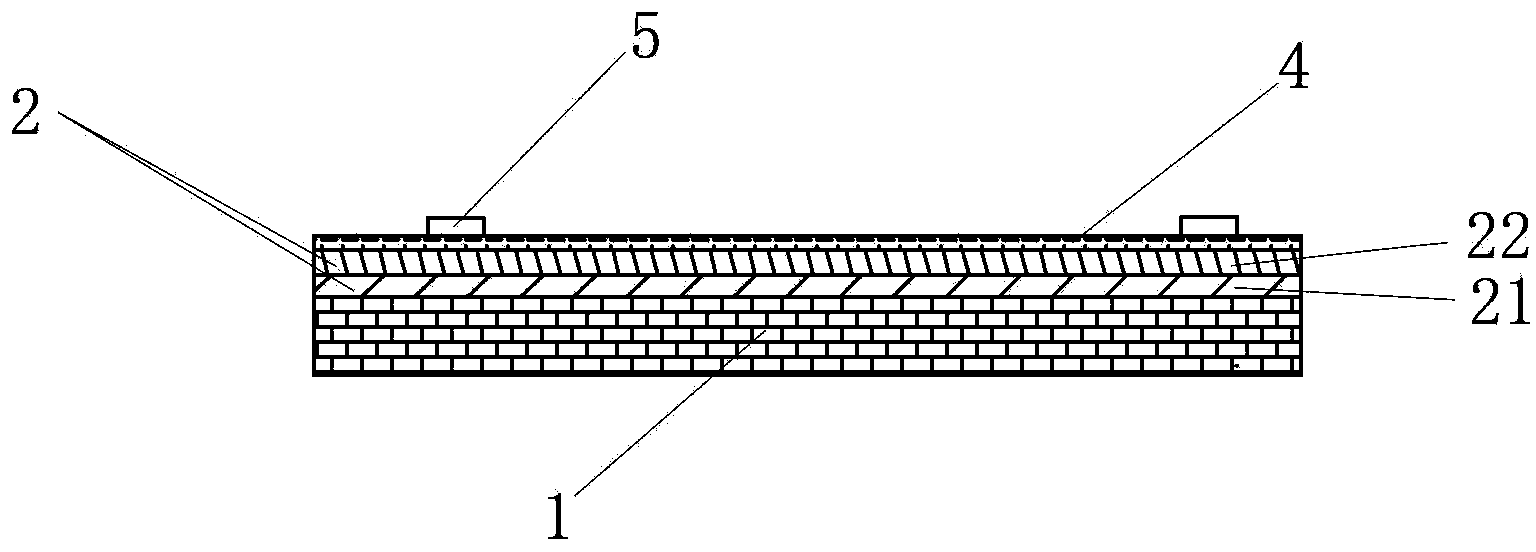

[0061] See image 3 , The rest of this embodiment is the same as that of Embodiment 1, except that: the heat preservation device of the glass tank kiln of this embodiment also includes a reflective layer 4 . The reflective layer 4 is an aluminum plate or galvanized iron sheet with a thickness of 0.5 mm, covering the outer surface of the first airgel insulation blanket layer 22 of the thermal insulation composite layer 2, and the fixing part 5 is arranged outside the reflective layer 4, so that the reflective layer 4 and The thermal insulation composite layer 2 is pressed sequentially from the outside to the inside, and is compacted on the outer surface of the thermal insulation layer 1 of the glass tank kiln.

[0062] Compared with the heat preservation device of embodiment 1, the heat preservation device of this embodiment can reflect a part of the heat radiated from the heat preservation layer 1 of the glass tank kiln back to the heat preservation layer 1 due to the existenc...

Embodiment 3)

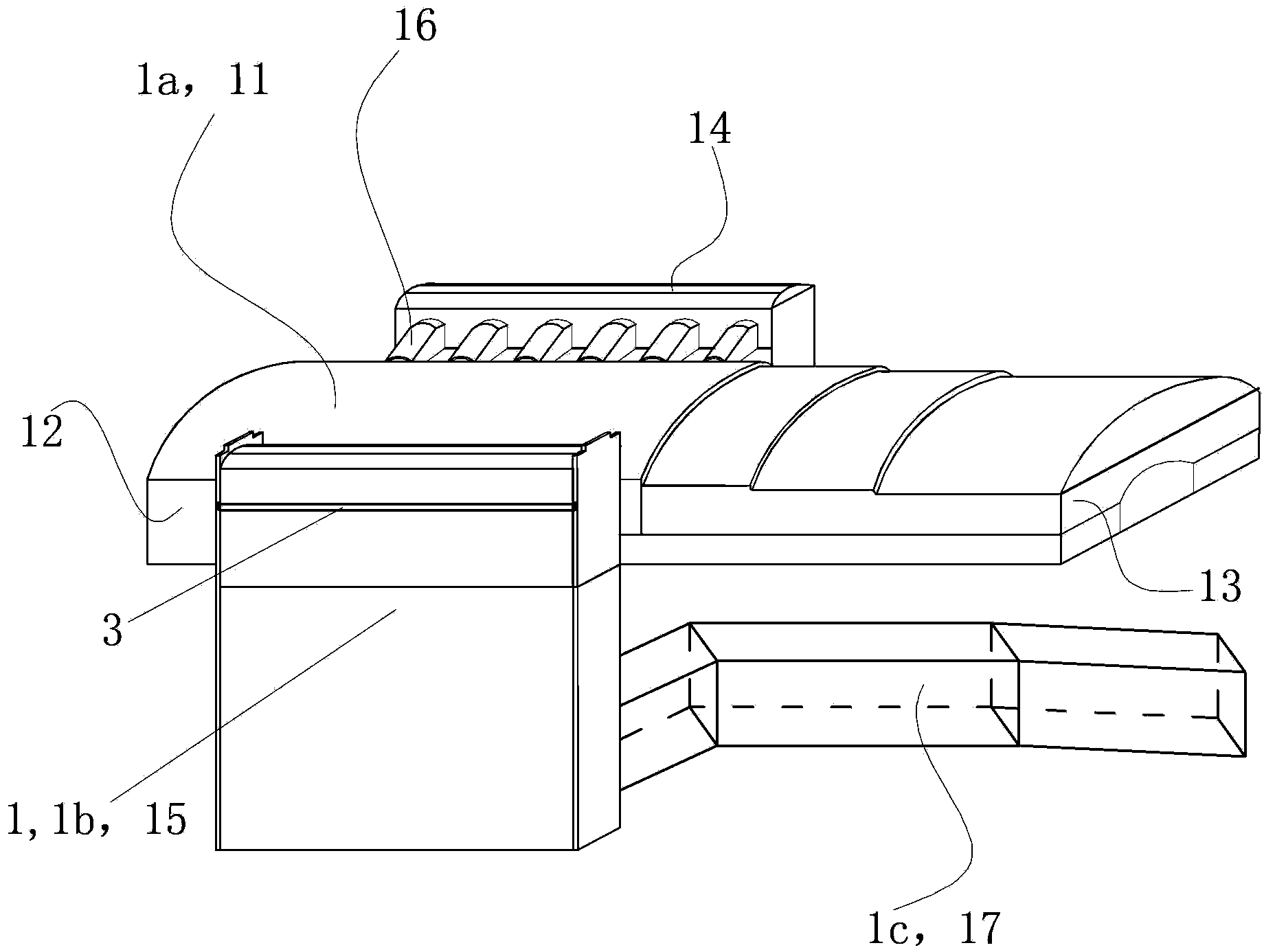

[0064] See Figure 4 with Figure 5 , the rest of this embodiment is the same as that of Embodiment 1, except that: the thermal insulation device of this embodiment also includes a thermal insulation composite layer 3 . The thermal insulation composite layer 3 is divided into a single thermal insulation composite layer 3a and a double thermal insulation composite layer 3b according to the number of glass fiber felt layers and airgel thermal insulation blanket layers included. The single thermal insulation composite layer 3a has only one composite layer, that is, the first glass fiber felt layer 31 and the second airgel thermal insulation blanket layer 32 are arranged sequentially from inside to outside. The double thermal insulation composite layer 3b has 2 composite layers, that is, the first glass fiber blanket layer 31, the second airgel thermal insulation blanket layer 32, the second glass fiber blanket layer 33 and the third airgel thermal insulation blanket layer 34 acc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com