One-time double-sided frictioning calendering line

A double-sided rubbing and calendering technology, applied in the field of rubber calendering, can solve problems such as the inability to achieve clear surface texture, high-strength adhesion and good wear resistance, the inability to guarantee the process temperature, and the inability to meet the process formula. The quality of rubbing glue, ensuring the quality of rubbing glue, and solving the effect of high production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The specific implementation manners of the present invention are further explained below in conjunction with the examples and accompanying drawings, but are not intended to limit the present invention.

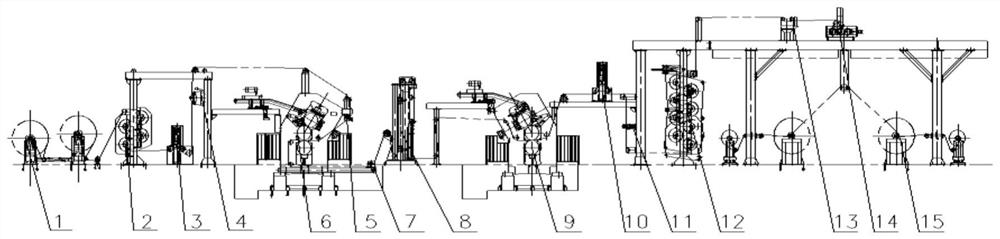

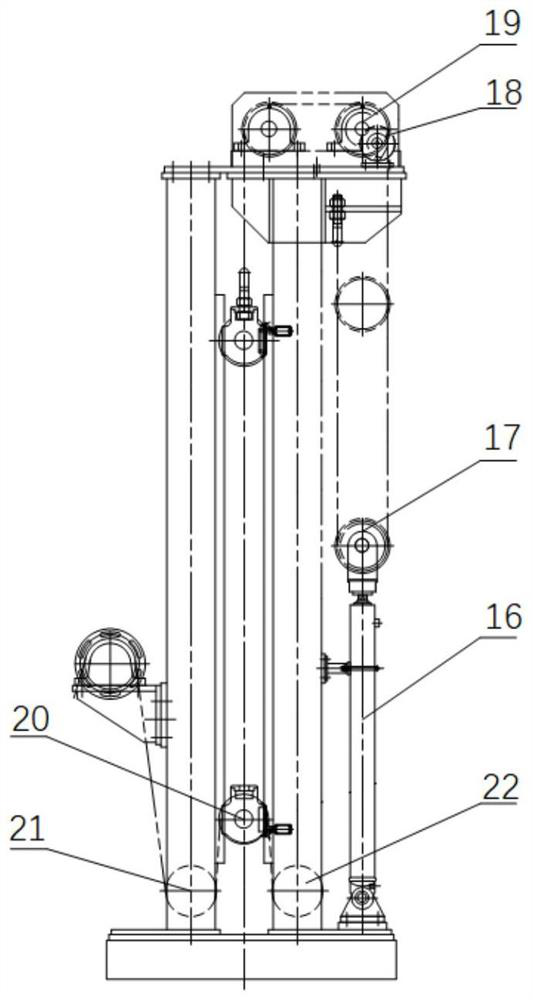

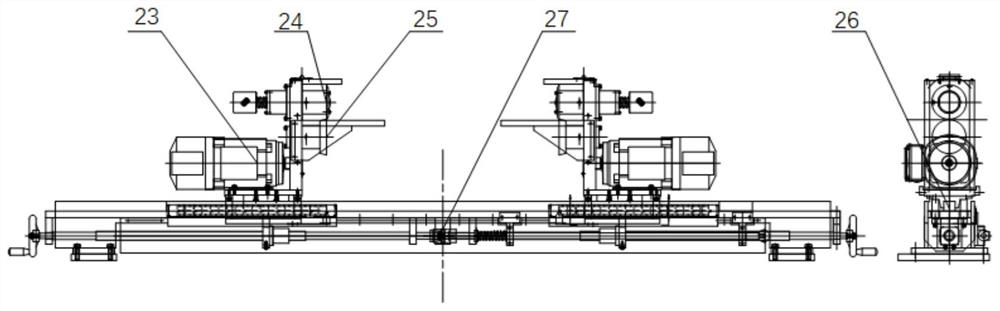

[0018] like figure 1 The one-time double-sided gluing calendering line shown uses two hydraulic distance-adjustable three-roll calenders and a set of calendering linkage device to complete a double-sided gluing process (applicable to different process formulas for upper and lower gluing). The calendering line includes a double-station guide device 1, a drying device 2, a front tension protection device 3, a large tension centering device 4, a spreading device 5, a 1# hydraulic distance-adjustable three-roll calender 6, and a connecting device connected in sequence. Conveyor 7, hydraulic tension adjustment device 8, 2# hydraulic distance adjustable three-roll calender 9, rear tension protection device 10, adhesive tape cutter device 11, cooling device 12, small tension c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com